- Semiconductors & Devices

FOR IMMEDIATE RELEASE No. 3748

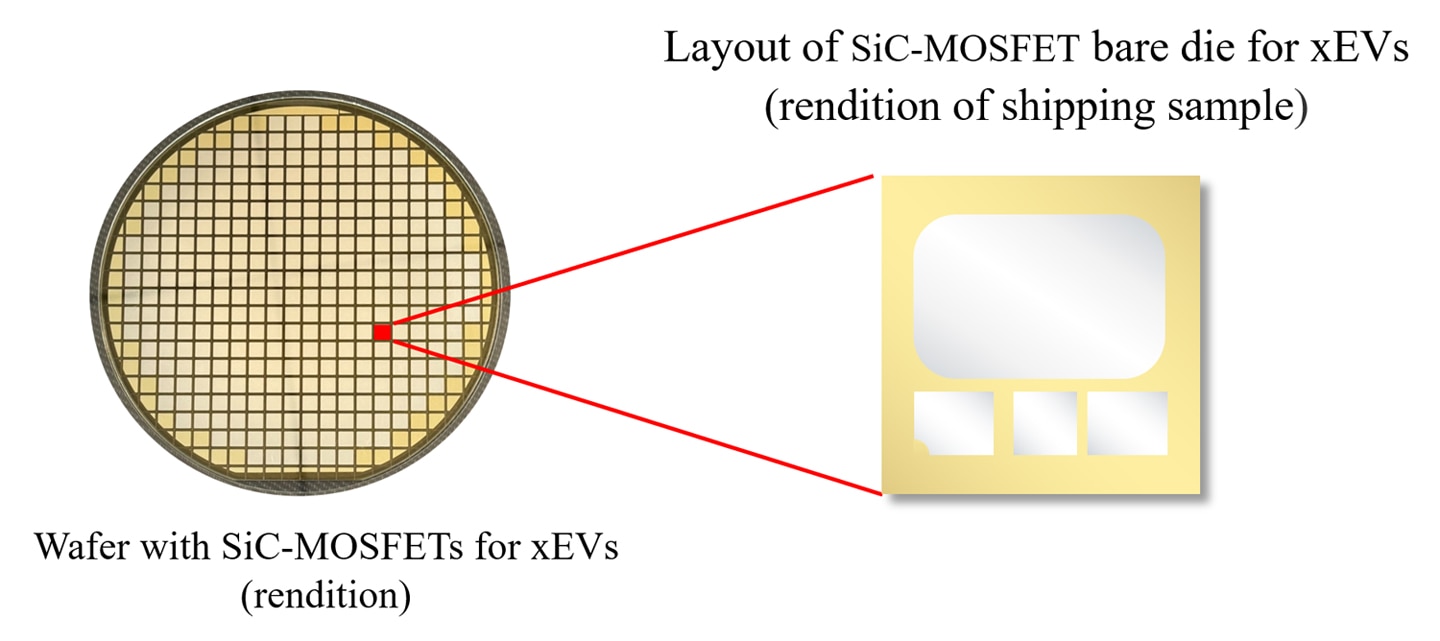

(left) Wafer with SiC-MOSFETs for xEVs (rendition) (right) Layout of SiC-MOSFET bare die for xEVs (rendition of shipping sample)

TOKYO, November 12, 2024 - Mitsubishi Electric Corporation (TOKYO: 6503) announced today that it will begin shipping samples of a silicon carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) bare die for use in drive-motor inverters of electric vehicles (EVs), plug-in hybrid vehicles (PHEVs) and other electric vehicles (xEVs) on November 14. Mitsubishi Electric's first standard-specification SiC-MOSFET power semiconductor chip will enable the company to respond to the diversification of inverters for xEVs and contribute to the growing popularity of these vehicles. The new SiC-MOSFET bare die for xEVs combines a proprietary chip structure and manufacturing technologies to contribute to decarbonization by enhancing inverter performance, extending driving range and improving energy efficiency in xEVs.

Mitsubishi Electric's new power semiconductor chip is a proprietary trench* SiC-MOSFET that reduces power loss by about 50% compared to conventional planar** SiC-MOSFETs. Thanks to proprietary manufacturing technologies, such as a gate oxide film process that suppresses fluctuations in power loss and on-resistance, the new chip achieves long-term stability to contribute to inverter durability and xEV performance.

- *Groove (trench) is dug from the surface of the wafer and the gate electrode is embedded.

- **Gate electrode is placed on the surface of the wafer.

Inquiry

Media contact

Related articles

- Semiconductors & Devices