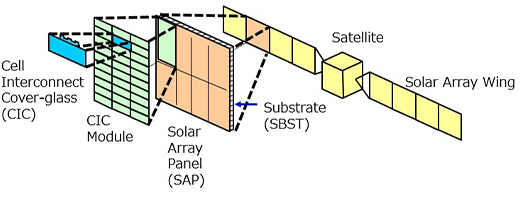

Solar Array Products (SAP,SAW,SPM)

Our lineup of solar array products, which is designed exclusively for the spacecraft, is lighter, more efficient, and more resistant to cosmic radiation than those for terrestrial use. We are capable of meeting various types of demand for solar array products: CIC, CIC Module, SAP, Substrate and SAW (Solar Array Wing). Furthermore, we are constantly striving to develop new products, such as SPM and SAW, to meet the changing needs of global customers with our experienced crew, state-of-the-art technology, manufacturing, and testing facilities

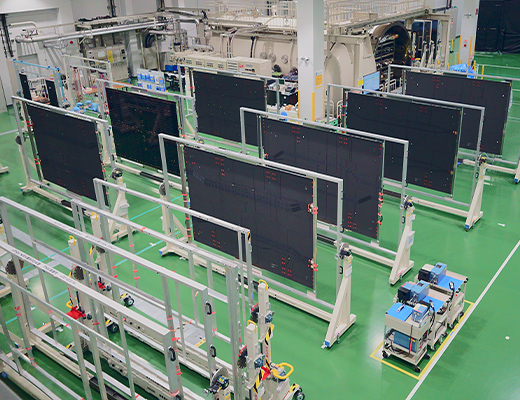

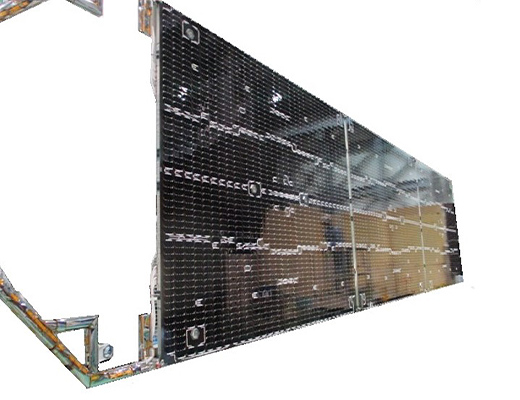

Solar Array Panels in Sagami Factory

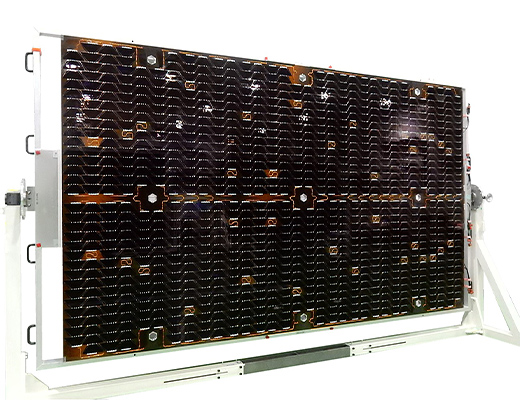

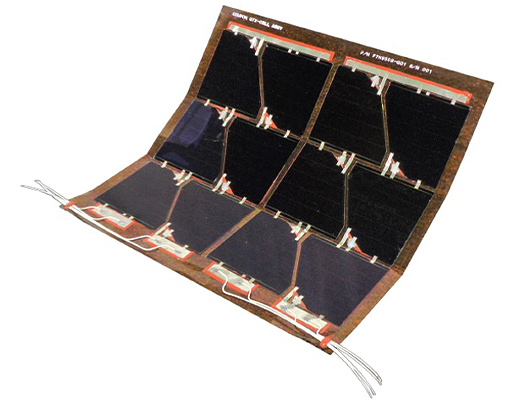

Solar Array Panels in Sagami FactorySolar Array Panel (SAP) for Rigid Solar Array Wing

- More than 1,800 Panels have been delivered to global customers since 1992. No failure reported.

- Flexible to various Photovoltaic Array (PVA) requirements.

- Fully automated processes (*1) applied to CIC assembly, stringing and laydown.

- Long-Term Purchase Agreements with major satellite manufacturers in US and Europe.

- Examples of adopted project: Intelsat, Eutelsat, Echostar…etc.

Data Sheets

Solar Array Panel

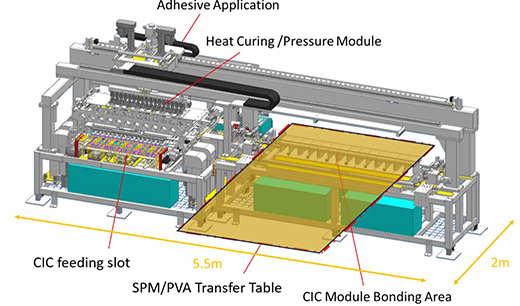

*1 Key process of PVA products, CICing and stringing has been fully automated, also laydown process has been semi-automated, by introducing new automated machines below. Both are applicable to Solar Array Panel and Solar Power Module.

Automated Laydown Machine:

- Applicable to Solar Array Panel and Solar Panel Module

- Laydown process of adhesive mixing, CIC (*) alignment, applying adhesive to CIC rear side, CIC placement to designated location, applying pressure and curing are all automated. (*) Connector Integrated Cell

- Internal heat curing by heat and pressure to reduce cycle time

- Enable to achieve 4 times as efficient as current machines’ productivity

Automated CIC Welding Machine:

- Automated CIC welding machine performs the multiple welding of interconnector and bypass diode consecutively onto the variable types of solar cells

- MELCO’s automated CIC welding machine completed more than 300 thousand of CICs for space use over the last 5 years complying with global standards of AIAA or ECSS.

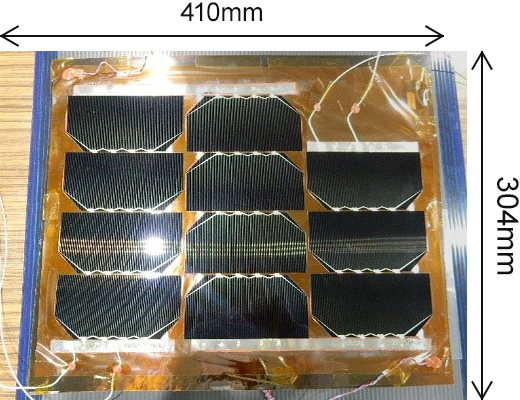

Solar Power Module (SPM) with Rigid Cells

- Developed through MELCO’s in-house research & development (R&D).

- Combines flexible plastic film and heritage Photovoltaic Array (PVA) technologies.

- Fully automated processes applied (*1) to CIC assembly, stringing and laydown.

- Validation (*2) completed successfully on the SPM sample with 6” wafer-based.

Data Sheets

Solar Power Module

*2 Demonstration successfully completed for NASA project with no degradation after all validation tests below:

- Fundamental tests

- Mechanical tests (roll-unroll)

- Thermal cycling tests for LEO (-105˚C to +75˚C, 886 cycles)

- Very low temperature thermal vacuum test (-200˚C to +110˚C, 3 cycles)

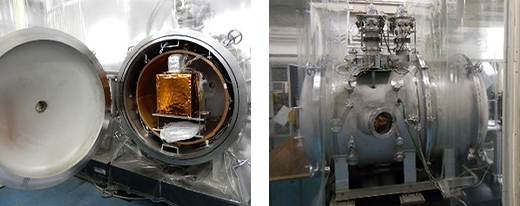

Low Temperature T/V Chamber

Low Temperature T/V Chamber

used for the validation Demonstration Coupon

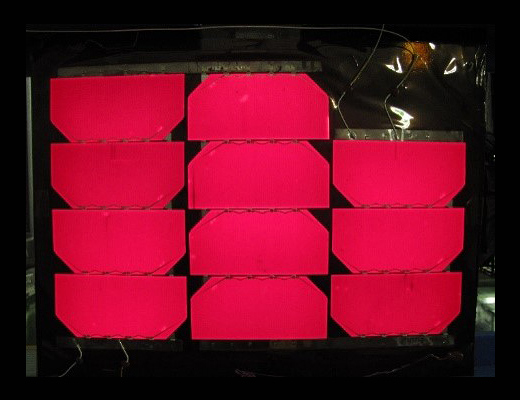

Demonstration Coupon El Image after

El Image after

Very Low Temp. in TVAC

Solar Array Wing

- More than 70 wings have been delivered to global customers.

- Panel deployment with spring force and motorless mechanism realizing lightweight and high reliability.

- No failure reported during on-orbit operation with various power range/orbit (LEO/GEO/Lunar) for more than 20 years since the first flight.

Data Sheets

Coming soon

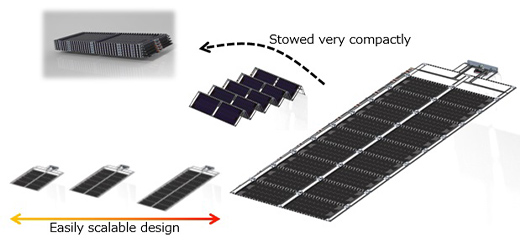

New Solar Array Wing (Under development)

- Developed in corporation with JAXA in research & development (R&D) program.

- Lower cost, mass productivity, lower stowed volume and easily scalable design than conventional rigid wings.

- Qualification to be completed by 2026.

Data Sheets

Coming soon

Solar Array Panel Substrate

- More than 2,600 substrates have been delivered to global customers since 1976.

- 3 separate autoclaves available to accommodate diverse requirements.

- Various sizes and types are available upon request.

Data Sheets

Solar Array Panel Substrate