SolutionsTotal Maintenance

In today’s dramatically changing business environment, the impact of sudden equipment downtime on corporate profits is enormous, and an increasing number of businesses are implementing planned equipment maintenance with the aim of achieving non-stop factories.

Meanwhile, the manufacturing industry faces another major issue of passing down the expertise of highly experienced employees.

Case15Immediately detecting errors and identifying error locations in machining tools

Corrective

Maintenance

Line level

Detecting machining abnormalities instantly can be difficult.

The error location can be difficult to identify even when an error is detected.

Immediately detect errors with machining error diagnosis/Identify error locations in machine tools by comparing waveforms

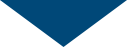

With iQ Monozukuri Tool Wear Diagnosis for Machine Tools, create a machining error diagnosis model from the machining IoT data to detect machining errors immediately.

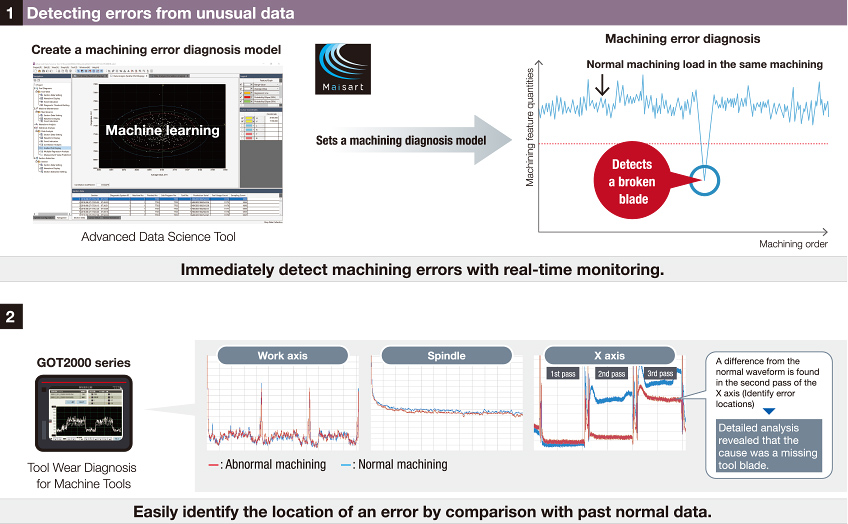

Identify the location of an error by comparing the abnormal machining data and the normal machining data on the Advanced Data Science Tool or GOT.

Immediately detect errors by monitoring the machining state in real time.

Quickly troubleshoot errors by identifying the error location through comparing overlaid waveforms.