SolutionsTotal Maintenance

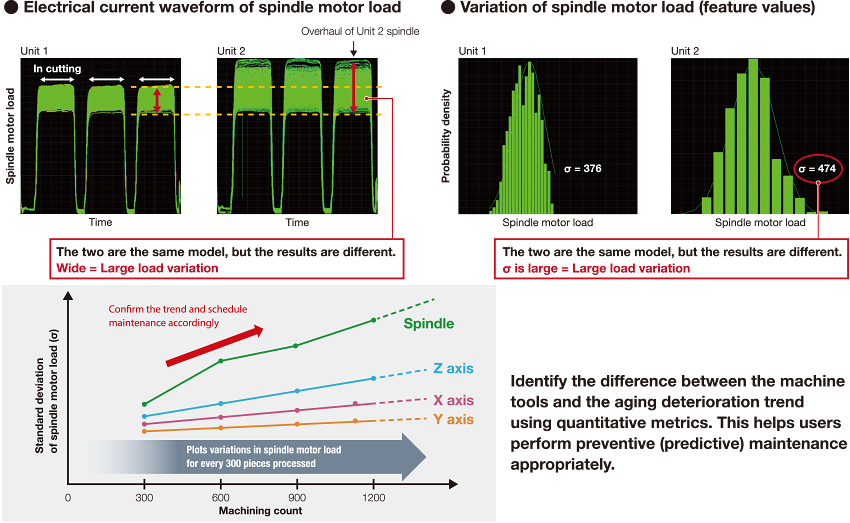

In today’s dramatically changing business environment, the impact of sudden equipment downtime on corporate profits is enormous, and an increasing number of businesses are implementing planned equipment maintenance with the aim of achieving non-stop factories.

Meanwhile, the manufacturing industry faces another major issue of passing down the expertise of highly experienced employees.

Case04Running laser-processing machines in continuous automatic operation

Predictive

Maintenance

Equipment level

(1) Processing defects occur during automatic operation at night, so upon arriving on-site the next morning, the processing machine has stopped and workpieces have not been finished.

(2) Adjusting programs when processing defects occur is time-consuming.

Utilize AI to support continuous automatic operation

An AI-assisted function automatically detects and adjusts processing defects to optimal machining conditions to support continuous automatic operation of processing machines.

(1) Reduces manual adjustment for rectifying processing defects and

enables operation to automatically continue.

(2) Helps prevent sudden stoppages of processing machines during

nighttime and weekend operation.