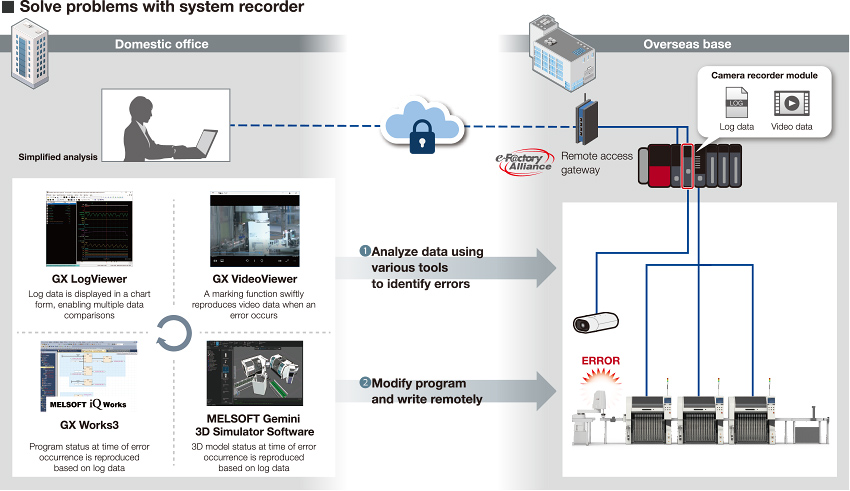

SolutionsTotal Maintenance

In today’s dramatically changing business environment, the impact of sudden equipment downtime on corporate profits is enormous, and an increasing number of businesses are implementing planned equipment maintenance with the aim of achieving non-stop factories.

Meanwhile, the manufacturing industry faces another major issue of passing down the expertise of highly experienced employees.

Case13Using robots reliably

Corrective

Maintenance

Device level

Need to compare the current condition of a robot with when the robot was first introduced because errors that did not occur at first-time use have been occasionally occurring.

Automatically collect daily operational information and periodically save robot program

Daily operational information is automatically saved, enabling status check at the time of introduction.

Backup data is automatically saved periodically, enabling restoration from the calendar.

Easily compare the condition of robots with and without errors by automatically aggregating the robot daily operational information and managing the history data.

Restore robot programs anytime from automatically backed up data in the SD card.

In case of sudden failures, these failures can be quickly resolved.