The Inside View

Hiroshi Nishiyuki highlights how IloT applications can deliver ‘visible’ results

First Published in Japanese in May 2021 [3 parts]

Part 3: Streamlining maintenance operations in factories reduces downtime and cost

For factories, it can be difficult to secure capital investment budgets to purchase new equipment. It’s one of the reasons why companies are increasingly looking for ways to extend the life of their existing assets, in which maintenance plays an important part. In recent years, attention has turned to predictive maintenance, meaning industrial internet-of-things (IIoT) achieved with sensors or leveraging AI technologies to collect data and detect signs of wear before equipment fails. Such prewarning helps prevent unexpected downtimes and optimize the component replacement cycle.

What is maintenance?

Hiroshi Nishiyuki, Head of Mitsubishi Electric’s FA Systems Design and Engineering, explains the importance of maintenance, “Do you drive a car in your everyday life? As many drivers might already know, car owners need to have their cars inspected and serviced regularly, and the associated maintenance must be performed by a qualified mechanic. The engine oil also needs replacing periodically, and wear parts like tires and brake pads need to be swapped out regularly, for example when they reach the pre-determined usage limits.”

During a service, if a component has not yet reached its usage limit but it is expected to exceed it before the next inspection, the mechanic will often replace it, incurring costs for labor and parts. On the other hand, regardless of the timing, if the car has a flat tire or it suddenly breaks down, it needs to be fixed as soon as possible.

Nishiyuki continues, “In a factory, the downtime of manufacturing facilities and equipment can affect the production plan, impacting the entire organization. That’s why maintenance engineers carry out daily inspections and replace components when they reach their usage limits before problems arise and fix equipment quickly if problems do occur.”

According to the Japanese Industrial Standards (JIS), this type of maintenance is defined as “preventive maintenance” and “corrective maintenance” respectively.

Total maintenance solutions for factories

In the current economic climate, it can be difficult to secure budgets for capital investment to purchase new equipment. That’s why companies are increasingly looking for ways to extend the life of their assets; maintenance plays an important part in this.

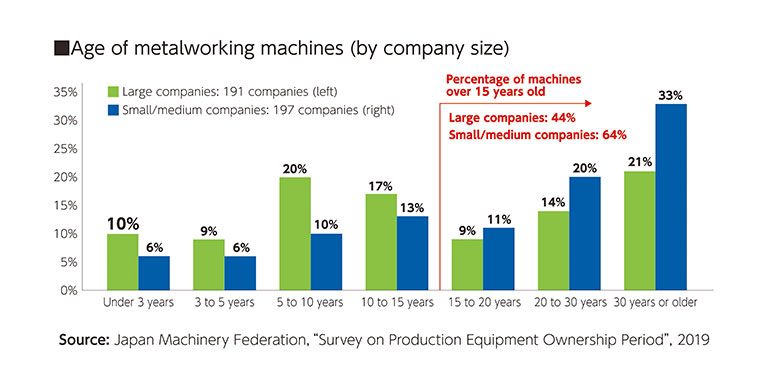

According to a survey by the Japan Machinery Federation in 2019, over 50% of metalworking machines in Japan have been in operation for 15 years or more, and over 25% are at least 30 years old. Such data shows the importance of maintenance.

Nishiyuki explained, “In recent years, attention has turned to predictive maintenance. This typically means industrial internet-of-things (IIoT) linked with sensors or leveraging AI technologies to collect data and detect signs of wear before equipment fails.” Such prewarning helps prevent unexpected breakdowns and optimize the component replacement cycle.

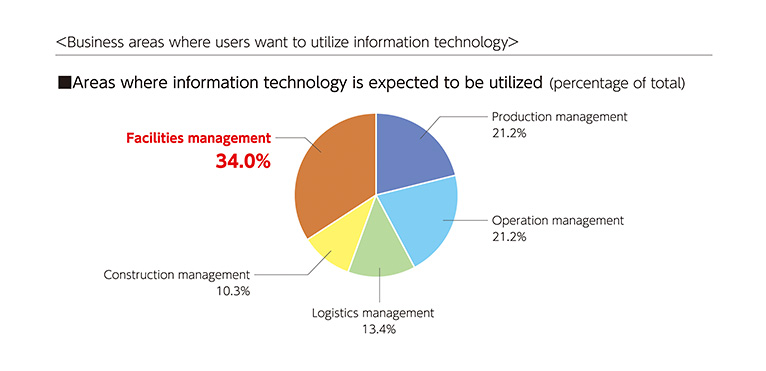

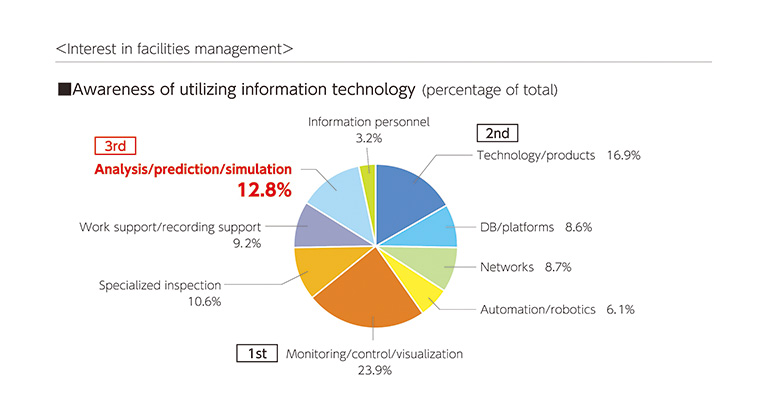

According to a survey carried out by the Japan Institute of Plant Maintenance in 2020, in terms of areas where technologies such as the IIoT and AI are expected to be utilized, the top answer (over 30%) was facilities management, with analysis/prediction/simulation in third position for how it would be leveraged.

Reflecting on the current interests in the manufacturing industry, Nishiyuki emphasized, “To meet the needs of companies across industries, Mitsubishi Electric’s Total Maintenance Solutions provide comprehensive support for maintenance operations. By leveraging IIoT to collect data about equipment conditions, then using AI for analysis and predictive diagnostics, it is possible to achieve efficient, data-driven maintenance.”

“Predictive and preventive maintenance help to avoid issues before they arise. Corrective maintenance addresses equipment failures once these have occurred. Mitsubishi Electric has a wide range of solutions for any scale of equipment or production line, supporting customers in all aspects of their maintenance activities.,” added Hiroshi Nishiyuki.

Click here for more details on “Total Maintenance Solutions”

Below are some relevant case studies highlighting such solutions.

Predictive maintenance

Smart solutions at the “Yukimi Daifuku” ice cream factory: the first step towards a fully automated system

Confectionery manufacturer Lotte is proactively working towards making its Urawa Factory smarter. The flagship of this facility is the “Yukimi Daifuku” ice cream production line, where predictive maintenance and continuous quality improvement strategies are being realized using real time data analysis and edge computing solutions.

Case study: Lotte Co. Ltd, Urawa Factory

Case study: Lotte Co. Ltd, Urawa FactoryMaking the “Yukimi Daifuku” factory smart ― Real-time millisecond level data acquisition and analysis

Preventive maintenance

Confectionery manufacturer Takeuchi Confectionery implements IIoT-based preventive maintenance solutions

IIoT is seen as an advanced technology, but the work of operators remains a key element in the confectionery business. One manufacturer, the Takeuchi Confectionery Group in Kaga, Ishikawa in Japan, has successfully implemented preventive maintenance strategies by harnessing IIoT-driven technologies for their process in baking “Kintsuba”, which are steamed red-bean sweets. They introduced a diagnostic solution that can predict the number of times a given asset can be used based on its condition.

Corrective maintenance

MELSEC iQ-R System Recorder significantly streamlines root cause analysis for equipment failure

At a highly automated production site, it can sometimes be difficult to pinpoint the precise cause behind equipment malfunctions. Using Mitsubishi Electric’s MELSEC iQ-R System Recorder module, which links PLC data with video recordings, factories can significantly reduce the work involved in troubleshooting.

System Recorder reduce the time for investigating the cause of equipment trouble by 93%

Click here for details on Mitsubishi Electric’s MELSEC iQ-R System Recorder module

Forewarned is forearmed

Implementing technologies to enable predictive maintenance requires investment. So, why should companies pay to introduce such a system? The answer is that, even if problems only occur rarely, the downtime associated with equipment failure can be very costly.

Hiroshi Nishiyuki added, “A similar argument can be applied to the implementation of cybersecurity measures. As IIoT-driven solutions and smart factories become more widespread, more pieces of equipment and facilities are being connected to communications networks. This means that the status of equipment can be viewed from the shop floor or remote locations, with relevant data readily accessible on the Cloud.”

For both predictive maintenance and cybersecurity, it can be difficult to see a direct return on investment, because issues only occur rarely. Even if a company is willing to invest in predictive maintenance, it may be reluctant to invest in cybersecurity, because enterprises generally don’t think their factories would ever fall victim to cyber attacks.

However, safeguarding against these events is similar to asking “What are you doing about the risk of fire?” Of course, companies need to take measures to prevent fires, but they must also decide in advance and practice what to do in case of one. Otherwise, a fire could cause significant damage and stop the factory from operating. This is a matter of risk management or business continuity planning (BCP), ensuring companies are prepared for a disaster, such as a fire or for example in Japan after an earthquake. Investment is necessary, but perhaps it is a matter of how much should be invested.

Recently, insurance companies have started offering cybersecurity insurance policies. This issue is now gaining more attention, as specialized consultants can perform simulations to show how much a company could lose as a result of a cyber attack.

To respond to concerns of such risks, Nishiyuki explained, “It is important to work with trusted partners who are capable of supporting companies to prepare for and minimize such risks. For example, Mitsubishi Electric has a product security policy and guidelines*1 for factory automation (FA) products used in factories. Its Nagoya Works and Industrial Mechatronics Systems Works production facilities are IEC 62443-4-1 certified, an international security standard for industry, and their product development process also meets various security requirements.*2”

The Japan Computer Emergency Response Team Coordination Center (JPCERT/CC)*3 has also published guidelines for industrial security as well as a security guide for introducing IIoT applications in factories.

*1 Details available here:

Product security

*2 Click here for details

Mitsubishi Electric news releases

Nagoya Works and Industrial Mechatronics Systems Works Awarded IEC 62443-4-1 Certification![]()

*3 Click here for details

JPCERT/CC (JPCERT Coordination Center)![]()

Conclusion

Hiroshi Nishiyuki concluded, “The manufacturing industry is currently going through unprecedented changes. Mitsubishi Electric continues to support these developments with the aim of helping customers through their own digital transformation journey. I recommend that companies find a trusted partner like Mitsubishi Electric, who they can consult with about specific issues or concerns about finding the most suitable solutions for factories.”

Products

- Summary

- Part 1: Practical Use of IoT to Deliver Machine-shop Benefit

- Part 2: Understanding the ROI of Visualization

- Part 3: Streamlining maintenance operations in factories reduces downtime and cost