Controllers MELSEC iQ-R Series Product features -System Recorder-

System recorder

Mitsubishi Electric's solution for improving productivity through easier data management

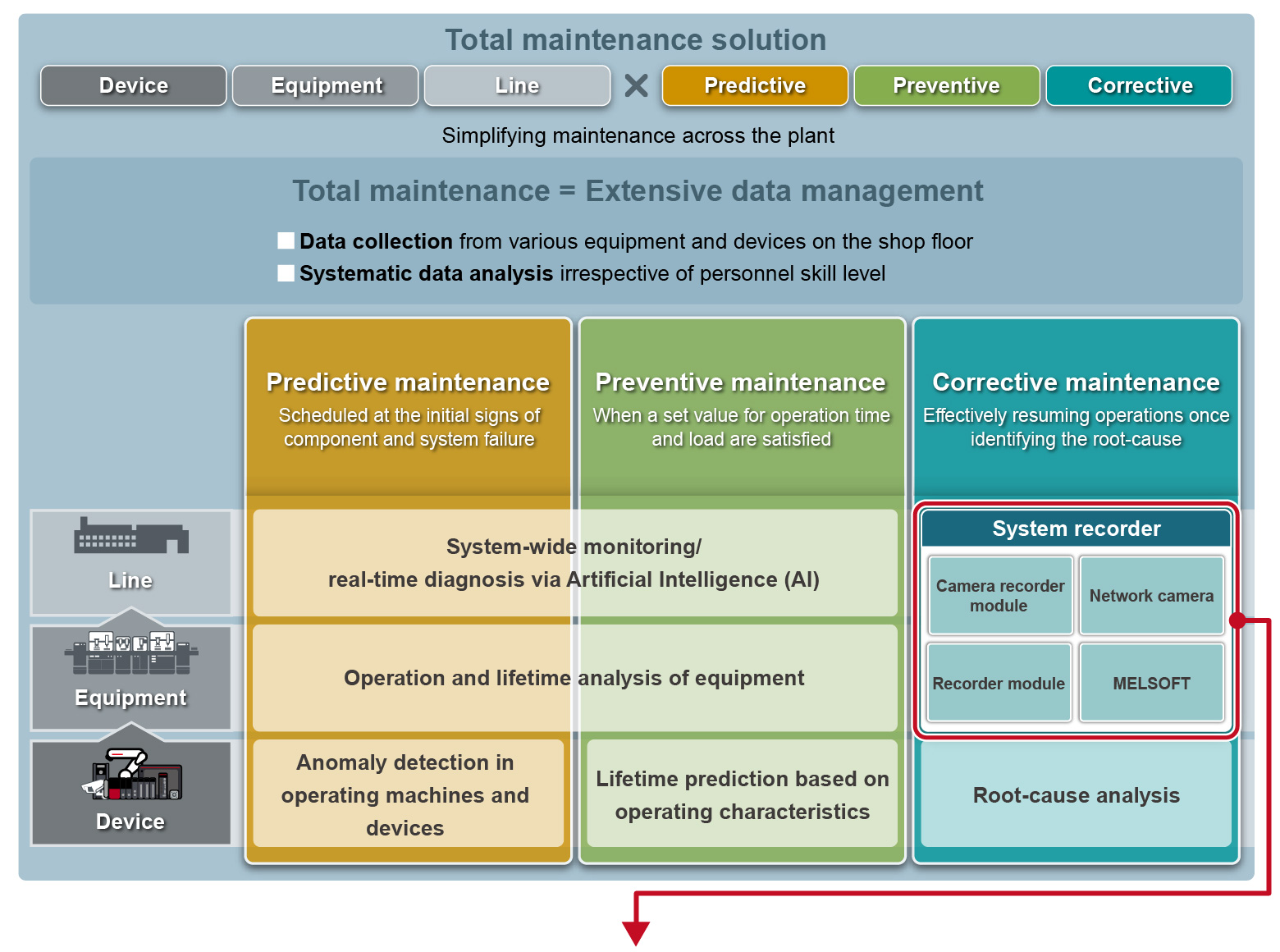

Maintenance is critical for ensuring continuous production. Maintenance includes ❶predictive maintenance to detect signs of error, periodical ❷preventive maintenance, and ❸corrective maintenance for prompt troubleshooting at the time of failure. Mitsubishi Electric proposes an enhanced maintenance solution by recording and sampling production and machine operating data and utilizing this data within various stages of maintenance.

The system recorder is a ❸corrective maintenance solution that ensures prompt troubleshooting and error prevention.

The system recorder is a corrective maintenance solution that ensures effective resumption of operations reducing downtime through its extensive system-wide data recording and simplified analysis software features.

System-wide recording and simplified analysis

System-wide recording

- Extensive recording ensures simpler cause analysis

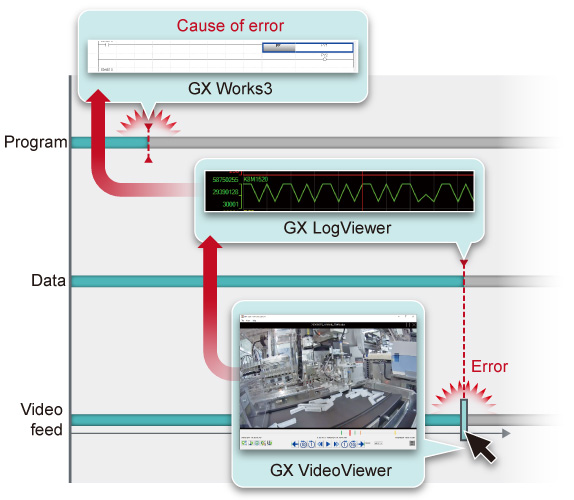

Error cause identification is made simpler by the extensive recording of various equipment and device data together with a real-time video feed reducing the need for multiple retesting due to insufficient data.

- System-wide recording

Irregularities between various equipment including control and drive systems together with operations are all linked.

- Automatic system-wide recording

Recording of errors that can occur outside standard operating shifts.

Simplified analysis

- Extensive data shown in the same timeline

Waveform, data, program, operations log, and video feeds are shown in sequence ready for analysis.

- Easier cause identification

Data flow analysis makes understanding the root-cause of failures easier by showing the relationship between failed and normal devices.

- Structured program ensures easier troubleshooting

Supports structured programs and device labels enabling easier resolution of problems, thereby reducing TCO*1.

- *1.TCO: Total Cost of Ownership

System-wide recording

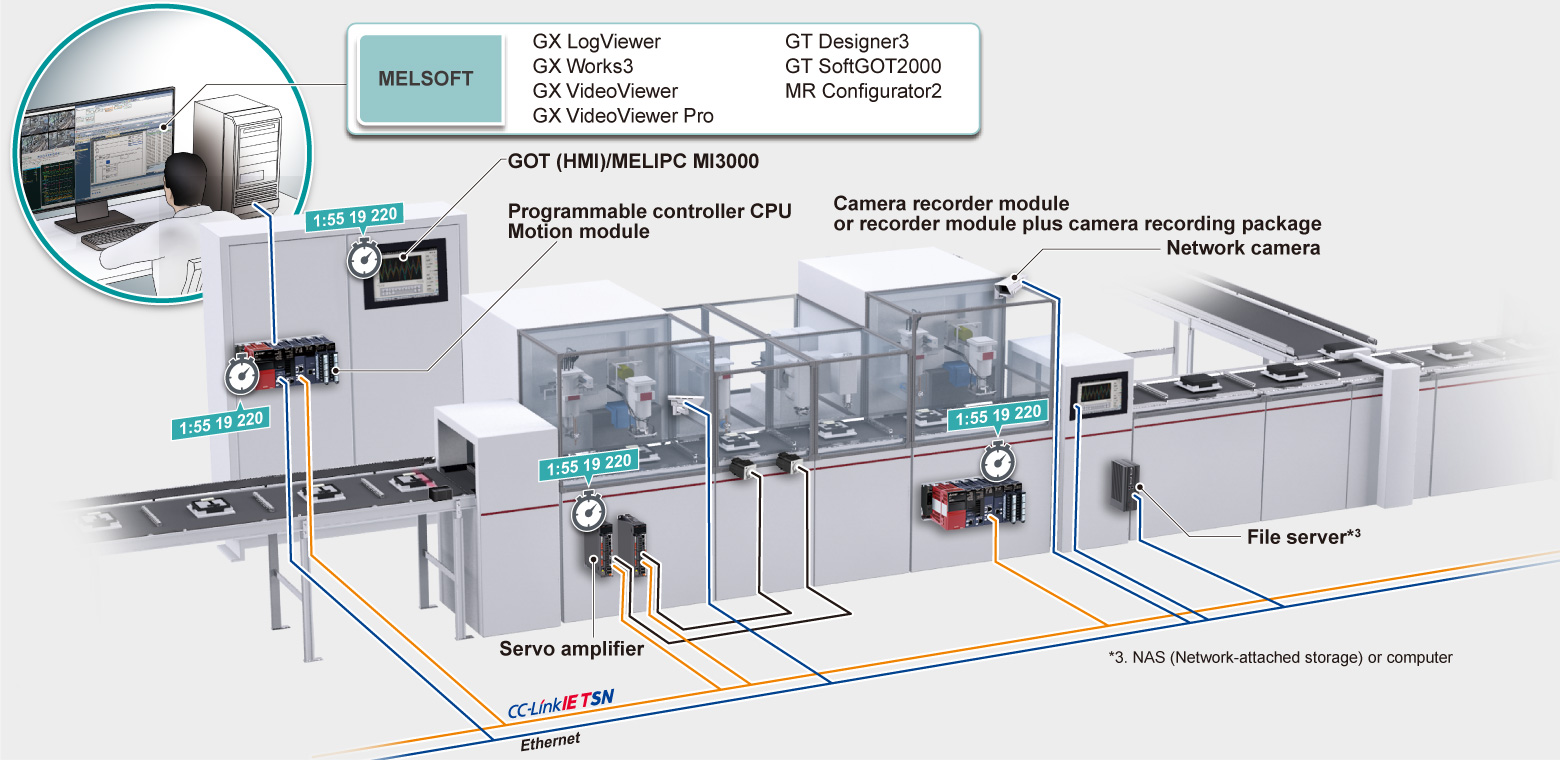

Control data

- Device/label collection every (programmable controller) scan

- Recording method according to applications

- Extensive recording trigger settings

- Automatic saving to file server

- Record video feeds at the moment an error occurs with network cameras

Video data

- Optimized focusing on camera subject

- Support high resolution and long-duration recording

- Collecting all servo axis data in real-time

- Co-recording function enables easier error cause identification by recording entire system data within compatible modules*2NEW

- Error cause identification via network across entire system by co-recording compatible modules*2NEW

Event history

Simplified analysis

- Log marker function

GX VideoViewer ProGX VideoViewerGX LogViewerGX Works3 - Difference extraction function

GX VideoViewer Pro - Offline monitoring

GX LogViewerGX Works3GT Designer3 - Data flow analysis function

GX Works3 - Simplified analysis of motion control

GX LogViewer - Simplified analysis using panel computer

GX Works3GX LogViewerGT Designer3GX VideoViewer

- *2.The recorder module, camera recorder module, motion CPU module, and motion module are supported.

System recorder demonstration movie

MELSEC iQ-R system recorder demonstration movie (English)

Movie about the camera recorder module which realizes downtime reduction through its extensive system-wide data recording and simplified analysis at an error.