The Inside View

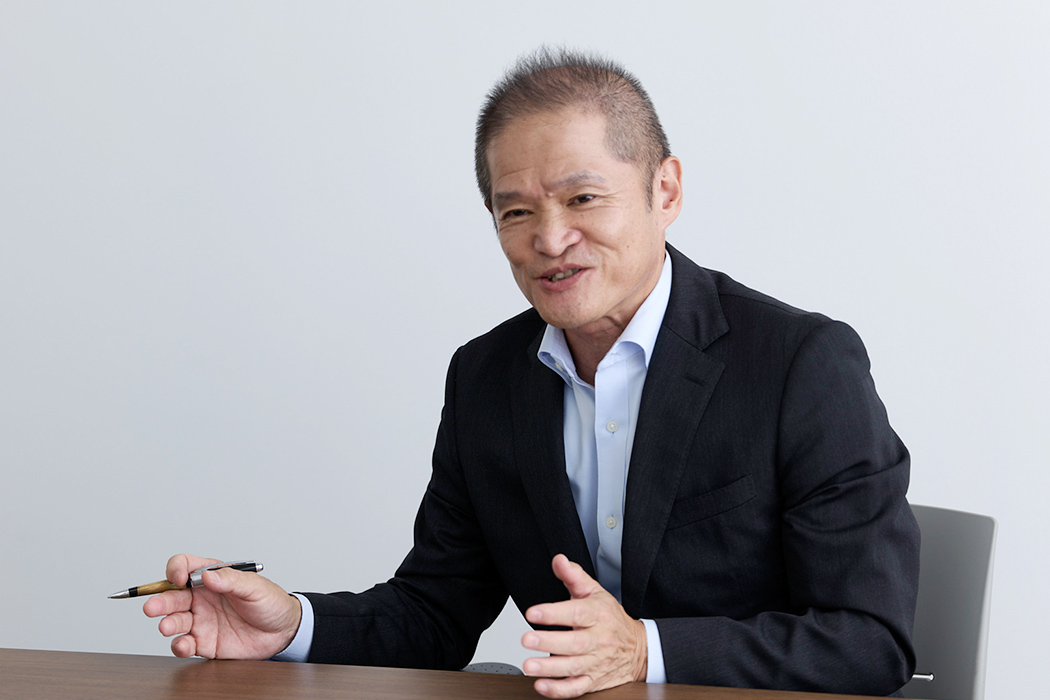

How Mitsubishi Electric servos earned a leading position in the Japanese marketSeisuke Tsutsumi

First Published in Japanese in February 2023 [3 parts]

Part 3: Working with customers to create innovative equipment

As we have seen in Parts 1 and 2, Mitsubishi Electric has developed a number of industry-leading technologies for servos. That is one of the reasons we managed to gain a high market share after a late start, but I believe there is another important reason: our customer-oriented approach. It is not enough to simply produce and sell advanced, high-performance servos. We cannot hope to win the support of the market without a positive attitude towards "working with customers to create innovative equipment to help them expand their business".

Meeting the challenges

I was once involved in a project to replace a hydraulic mechanism with a servo system for an equipment manufacturer.

Before starting this project, the goal we set with the customer was to "build the largest equipment in the world." The main challenge was the difficulty of getting a motor to instantaneously generate the large force that can be produced by hydraulic pressure. It would be possible to do this by increasing the output of the motor itself, but we did not have a motor that could handle such a large output at the time. So, with our philosophy of "working with the customer to create innovative equipment", we started by developing a new motor especially for this project.

The customer later exhibited the completed equipment at a trade show in the United States. This led to a request from a major U.S. manufacturer, asking us to sell them this motor. They must have looked closely at the equipment, realized that this motor was the key, and found us because of the model name printed on the nameplate. In the end, the sale didn't work out, but we were pleased that they knew we were working behind the scenes.

We still have a good relationship with the aforementioned customer, especially after working together to produce equipment so good that other companies wanted to imitate it. Somehow, I even got involved in the development planning of the customer's own equipment! I still have a personal friendship with the people I worked with on that project.

The project team

Another equipment manufacturer was working on a project to develop a machine to cover trays of food with plastic wrap. The challenge they faced was how to keep the serving of food on the tray, as it tended to fall off when lifting and stopping the trays for wrapping. The problem could be solved by making the lifting operation slower, but this would reduce productivity.

The customer even installed a high-speed camera to check the serving of food during the wrapping process. If a customer is willing to go to such lengths to increase productivity, we must be prepared to support them. We decided to use simulation to find the optimal motor operating pattern to ensure a fast wrapping process without damaging the food on the tray.

However, this was at a time of lower PC performance and when image simulation software simply did not exist. If we wanted to perform a simulation, we would have to develop our own software to do it. I think the customer was skeptical about how realistic this would be with a deadline they needed to meet approaching, but I said: "Leave it to me." So, we started development of the simulation program.

Much to the customer's delight, we ended up completing the whole process, from program development to finding the optimal operation pattern, in just one month. I am still in touch with the people I worked with on that project, too.

Earning our customers' trust

Trying to maintain an attitude of "working with customers to create innovative equipment" can sometimes lead to disagreements. While working with a machine builder on a project to develop manufacturing equipment for liquid crystal panels, we were tackling the difficult challenge of applying a thin, uniform film over the panels. This film was so thin that vibrations from the motor or even a passing truck would affect the equipment, causing variations in thickness.

It was difficult to develop a control system that would not vibrate, and we were not making much progress. The customer was very concerned and wanted to escalate the situation. It is a natural reaction when you are not sure what is happening, and you do not see any progress. However, I explained that the key to solving this was to work together. I felt that as engineers we knew most about the technology, and the customer knew most about their application, so together we should be able to solve the problem and help the customer to create a new innovative machine. Thankfully I managed to convince them, and with calm minds we eventually solved the issue and the project was successful. When the equipment was released, the catalog stated that a Mitsubishi Electric servo was used. I was delighted to see this proof that we had gained the customer's trust.

A servo needs to increase the added value of a customer's equipment so that they can make more profit. There are three ways to make more profit: selling more products, selling them at a higher price, or producing them for less. No matter how many new servo technologies and solutions we develop, it is meaningless unless it helps the customer in one of these ways.

Selling off technology does not lead to increased profits for our customers, either. Once, when we had delivered a servo system to a customer, they asked us to sell them the servo control program so that they could produce it in-house in future. Although they offered a high price, we refused. Our servo amplifier hardware is equipped with servo control configured with our own software, and that is why it performs so well.

What's more, without raising our customers' profits, it would be impossible for us to increase our own profit. Rather than simply creating products, the best way to demonstrate our value is through our ability to boost customer profits.

To help customers understand that the solutions we provide will lead to higher profits, we need to always be there at the customer's side. It is vital to stay close to be "in the know". I once found out that a customer was reading the Stories of the Romans historical novels by Nanami Shiono, so I set out to read all 43 books in the series so that we would have something in common to talk about. We had several meals together and talked about the books while I was working my way through the series. The same customer has since introduced me to many other titles, and before I knew it, I found I had finished over a hundred books.

We always aim to increase the customer's profits, and always stay close by the customer's side. We have pursued these aims for many years, and I believe that this, above all else, is why we have a large share of the servo market today.