Human-Machine Interfaces(HMIs)-GOT GOT2000 Series

Predictive maintenance

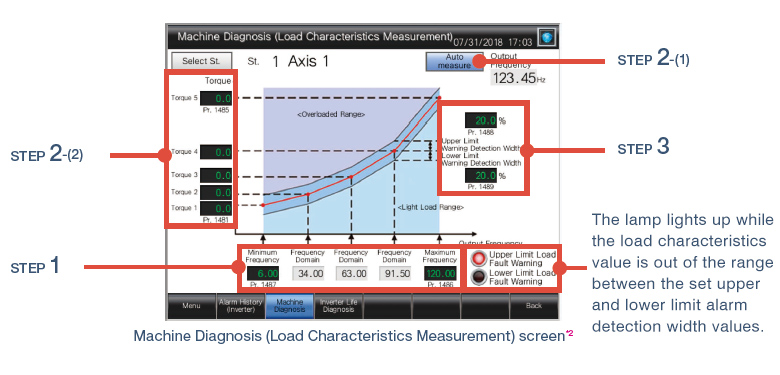

Machine diagnosis (load characteristics measurement)

- CASE1*1

- CASE2

- CASE3

- CASE4*1

- CASE5

Challenge

We want to detect clogged filters and clogged pipes!

Solutions

Detect system errors with the inverter, and display them on the GOT

The relation of output frequency and torque in the normal state can be saved in the inverter, and used to check whether the operation is taking place with a normal load. If the result is out of the normal range, an error or warning is output so that it is useful to detect system errors and perform maintenance work.

Set/display the range of frequency to detect load characteristics error.

- (1)The inverter automatically measures the relation of the output frequency and torque in the normal state, and calculates the load characteristics reference value.

- (2)The load characteristics reference value calculated in the above (1) is displayed. To finely adjust this value, change the value manually.

Set the upper and lower limit warning detection width (threshold value) against the load characteristics reference value.

The initial value is 20%.

<Possible error causes>

■ In overload range: clogged filter, clogged pipe, etc.

■ In light load range: broken belt, broken blade, idle run, etc.

- *1FR-E700-NE, FR-E700, and FR-D700 are not supported by machine diagnosis (load characteristics measurement).

- *2Sample screens (VGA) are available. The screen image is the sample screen of FR-A800-E for CASE 1. The screen image differs from the one for FR-E800. The sample screen of this function is not available for FR-E700/FR-D700 in CASE 4.

- *3Sample screens are not supported by GT23, GT21, GS21, and GT SoftGOT2000.

- *4Supported by GT SoftGOT2000 (Multiple channels) only.