Topics

- Semiconductors & Devices

- Topics

Expanding our SiC power semiconductor device business to achieve GX

The power semiconductor device plays a crucial role in our challenge to achieve GX (green transformation) with a view to a future where carbon neutrality and social change are possible.

SiC power semiconductor devices—which are made from compound semiconductor SiC (silicon carbide) that binds silicon (Si) and carbon (C) at a 1:1 ratio—offer significantly reduced power loss compared to conventional silicon-based power semiconductor devices while enabling high-temperature operation and high-speed switching. As such, SiC power semiconductor devices are anticipated to contribute to energy-saving in a diversity of power electronics devices, including home appliances such as air conditioners, industrial devices, train carriages, and cars. Therefore, rapid market expansion is predicted as SiC power semiconductor devices are adopted in electric vehicles.

Furthermore, a power semiconductor device utilizing gallium oxide (Ga2O3) is highly anticipated as a next-generation semiconductor wafer material.

In our challenge to achieve GX, Mitsubishi Electric will aim to expand our power semiconductor device business through various investments as well as R&D and commercialization of cutting-edge power semiconductor devices.

News : November 20, 2024

Power Device Works to Construct New Plant

News : November 20, 2024

Power Device Works to Construct New Plant

Mitsubishi Electric will invest approximately 10 billion yen to construct a new facility for the assembly and inspection of power semiconductor modules at its Power Device Works in Fukuoka Prefecture, Japan. The plant is scheduled to begin operations in October 2026.

News : March 14,2023

Construct New Wafer Plant to Boost SiC Power Semiconductor Business

News : March 14,2023

Construct New Wafer Plant to Boost SiC Power Semiconductor Business

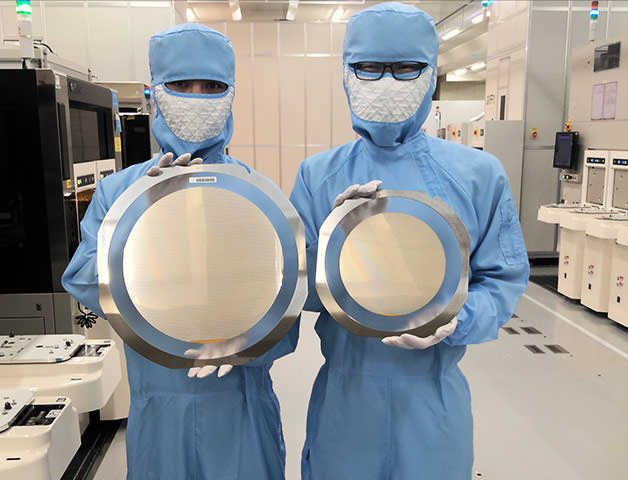

Mitsubishi Electric will double its previously announced investment plan to approx. 260 billion yen in the five-year period to March 2026 mainly for constructing a new wafer plant to increase production of silicon carbide (SiC) power semiconductors. A major portion of the increased investment, approximately 100 billion yen, will be used to construct a new 8-inch SiC wafer plant and enhance related production facilities. The new factory, which will incorporate an owned facility in the Shisui area of Kumamoto Prefecture, will produce large-diameter 8-inch SiC wafers, introduce a clean room featuring state-of-the-art energy efficiency and high-level automated production efficiency.

NEWS : October 10, 2023

Invest in Coherent's New SiC Business

NEWS : October 10, 2023

Invest in Coherent's New SiC Business

Mitsubishi Electric has agreed with Coherent Corp. to invest USD 500 million (approx. 75 billion yen*) in a new silicon carbide (SiC) business to be carved out from Coherent, aiming to expand its SiC power semiconductor device business by strengthening vertical collaboration with Coherent, who has been a supplier of SiC substrates to Mitsubishi Electric.

By further deepening its collaboration with Coherent through this investment, Mitsubishi Electric aims to stabilize its procurement of SiC substrates for SiC power semiconductor devices, for which demand is forecasted to grow rapidly, and thereby expand its supply of reliable high-performance SiC power semiconductor devices to meet rising global demand.

NEWS : May 26, 2023

Mitsubishi Electric and Coherent Enter into A Collaboration to Scale Manufacturing of SiC Power Electronics on A 200 mm Technology

NEWS : May 26, 2023

Mitsubishi Electric and Coherent Enter into A Collaboration to Scale Manufacturing of SiC Power Electronics on A 200 mm Technology

Mitsubishi Electric Corporate and Coherent Corp. have signed a memorandum of understanding (MOU) to collaborate on a program to scale manufacturing of SiC power electronics on a 200 mm technology platform. Under the MOU, Coherent will develop a supply of 200 mm n-type 4H SiC substrates for Mitsubishi Electric’s future SiC power devices manufactured at the new facility.

NEWS : Nov. 13, 2023

Mitsubishi Electric and Nexperia to Partner in Joint SiC Power Semiconductors Development

NEWS : Nov. 13, 2023

Mitsubishi Electric and Nexperia to Partner in Joint SiC Power Semiconductors Development

Mitsubishi Electric will enter into a strategic partnership with Nexperia B.V. to jointly develop silicon carbide (SiC) power semiconductors for the power electronics market. Mitsubishi Electric will leverage its wide-bandgap semiconductor technologies to develop and supply SiC MOSFET chips that Nexperia will use to develop SiC discrete devices.

NEWS : July 28, 2023

Mitsubishi Electric Buys Stake in Novel Crystal Technology to Accelerate Development of Gallium-oxide Power Semiconductors

NEWS : July 28, 2023

Mitsubishi Electric Buys Stake in Novel Crystal Technology to Accelerate Development of Gallium-oxide Power Semiconductors

Mitsubishi Electric has taken an equity position in Novel Crystal Technology, Inc., a Japanese company that develops and sells gallium-oxide wafers, a promising candidate for use in superior energy-saving power semiconductors that Mitsubishi Electric intends to develop at an accelerated pace in support of global decarbonization.

Mitsubishi Electric now expects to accelerate its development of superior energy-saving gallium-oxide power semiconductors by combining its own expertise in the design and manufacture of low-energy-loss, high reliability power semiconductors with Novel Crystal Technology's expertise in the production of gallium-oxide wafers.

News : September 30, 2024

Begins Supplying Power Semiconductor Chips Made from 12-inch Wafers for Semiconductor Module Assembly

News : September 30, 2024

Begins Supplying Power Semiconductor Chips Made from 12-inch Wafers for Semiconductor Module Assembly

Mitsubishi Electric Power Device Works' Fukuyama Factory has begun large-scale supply of power semiconductor chips made from 12-inch silicon (Si) wafers for the assembly of semiconductor modules, effective immediately. The advanced Si power semiconductor modules will initially be used in consumer products. Going forward, a timely supply of semiconductor chips will be ensured to meet the growing demand for energy-saving power-electronics devices across various applications.