Sustainability

Is “Sustainability” Sustainable?

June 2023 [2 Parts]

Part 2: SDGs in action!

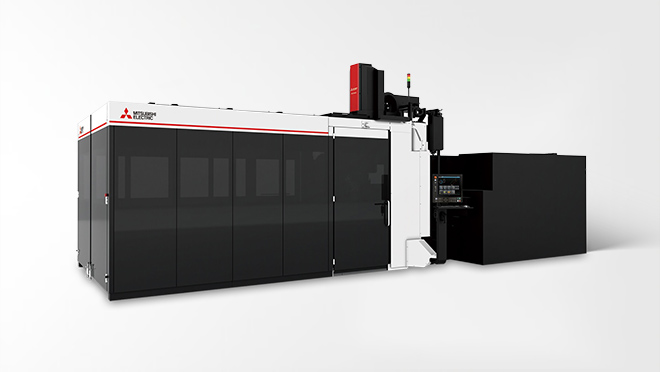

Award winning “national green factory”

Mitsubishi Electric Automation Manufacturing, a factory automation manufacturing plant based in Changshu China, has been certified by the Chinese government as a “national green factory” after extensive evaluation. The plant known as MEAMC, has achieved an overall 10% reduction in power consumption, which at a product level translates to 27% less energy being needed to manufacture each product. This has been achieved through the combined use of Mitsubishi Electric’s e-F@ctory intelligent manufacturing system and the use of E-JIT (environment & energy just in time) to simultaneously optimize environmental, energy and production efficiency.

A foundation that helps disabled youths join the workforce

The Mitsubishi Electric America Foundation (MEAF) was established in 1991 by Mitsubishi Electric Corporation Japan and the Mitsubishi Electric US group companies with an endowment of $15 million. Its mission is to help disabled youngsters to actively participate in society through maximizing their own potential. Since 2011 the Foundation’s vision has been to empower those affected through increased employment. According to the US CDC one in four Americans have some form of disability which for many prevents them from gaining employment opportunities. Of those that can work, often they are unable to find work, so to help address this issue the Mitsubishi Electric America Foundation launched its national M>PWR initiative in 2011. By investing its philanthropic resources in innovative approaches to prepare youths with disabilities for employment the foundation aims to plant the seeds of change and to identify strategies that are effective at scale in helping disabled youths transition into the competitive workforce.

A foundation that helps disabled youths join the workforce

The Mitsubishi Electric America Foundation (MEAF) was established in 1991 by Mitsubishi Electric Corporation Japan and the Mitsubishi Electric US group companies with an endowment of $15 million. Its mission is to help disabled youngsters to actively participate in society through maximizing their own potential. Since 2011 the Foundation’s vision has been to empower those affected through increased employment. According to the US CDC one in four Americans have some form of disability which for many prevents them from gaining employment opportunities. Of those that can work, often they are unable to find work, so to help address this issue the Mitsubishi Electric America Foundation launched its national M>PWR initiative in 2011. By investing its philanthropic resources in innovative approaches to prepare youths with disabilities for employment the foundation aims to plant the seeds of change and to identify strategies that are effective at scale in helping disabled youths transition into the competitive workforce.

SDG product contribution

A Commitment to Sustainability:

Delivering Both Economic and Social Value