Solutions

IoT Solutions for Machining Lines

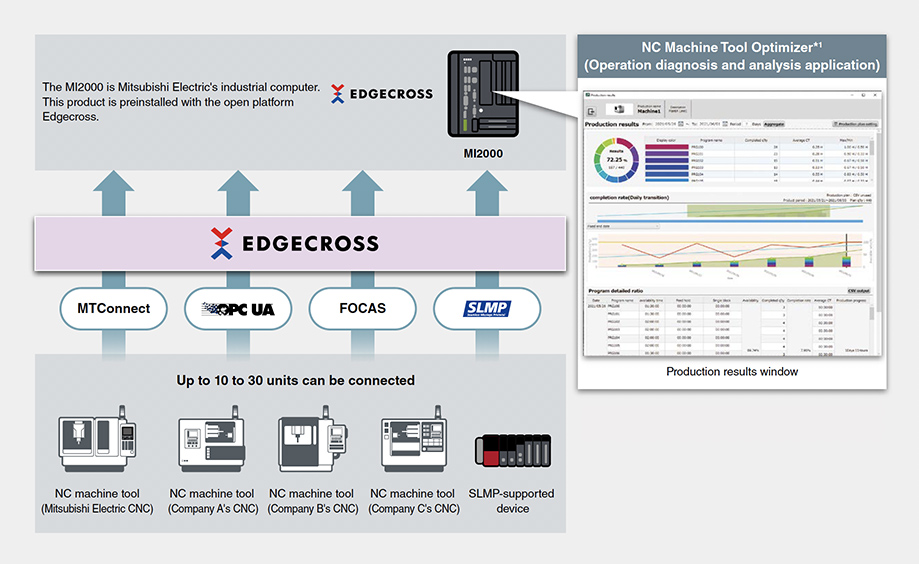

Case.02Allowing a wide variety of machine tools to be visualized and analyzed all together

- Monitoring

- Individual equipment

- Overall line

- Overall factory

Issues

Not all equipment is properly monitored and it is unknown whether each machine is running at optimal performance.

Equipment consists of new and old components from various vendors, and their respective data collection methods are complicated or unknown.

Equipment consists of new and old components from various vendors, and their respective data collection methods are complicated or unknown.

Solution

- NC Machine Tool Optimizer collects operation information from machine tools, PLCs, and peripheral equipment of various manufacturers and visualizes their operation statuses

- Operation statuses of all machine tools in the entire factory can be monitored by connecting multiple sites

- *1Depending on the edition of NC Machine Tool Optimizer, the supported models, protocols, and maximum number of connections may vary. For details, please refer to the product catalog.

Benefits

- Manage machine tools from multiple sites and vendors with the same indicator, which facilitates improvements on the shop floor and helps improve productivity