Solutions

e-F@ctory Alliance

As a solutions provider, we collaborate with many partners across all monozukuri fields. This ecosystem provides optimal solutions in various regions and fields in response to the issues experienced by our customers.

e-F@ctory Alliance Alliance Partner Cases

Producing entire production systems

Achieving advanced systems integration

Combining Mitsubishi Electric FA equipment and other products, systems integrators propose systems solutions for everything from shop floors to information systems to customers.

Development of application software strengthening connection affinity with Mitsubishi FA devices

Utilizing information-sharing products and technologies such as Mitsubishi Electric's EZSocket and SLMP, vendors develop and propose excellent application software and drivers that ensure the connection compatibility of Mitsubishi Electric FA equipment.

Provide device compatibility with Mitsubishi FA equipment Achieve improved system builds and maintainability

Manufacturers proposing peripheral equipment that is easy to connect with Mitsubishi Electric FA equipment and is easier to use.

e-F@ctory Alliance Worldwide

Please select the country / region where you currently live.

Americas

Asia-Pacific

Case.01

Engineering Design

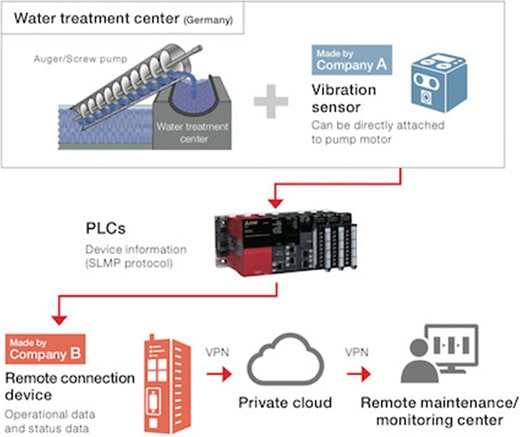

A status monitoring system possible through alliances between Device Partner A, who provides smart vibration sensors,and Device Partner B, who provides remote connectivity.

Discovered flaws in gears four months after installation.

Feature

- Vibration sensor produced by Company A packaged with PLC

- Plug & Play realizes easy installation

- Even without expertise knowledge, secure VPN environments can be built using the remote connecting device produced by Company B

- Build scalable status monitoring system in short period of time, and quickly recover short-term investment

Conceptual diagram

Case.02

Engineering Design/

Production/Operation

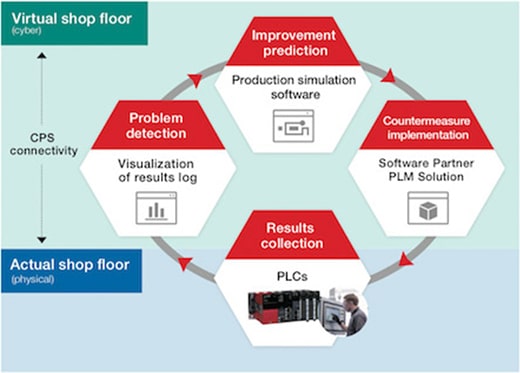

Supporting “Prediction of Improvement Results”by simulating production using “visualization”of shop floor results information collected by the PLC.

Feature

- “Visualization” of shop floor results information collected by the PLC in real-time for the early detection of shop floor issues

- Early detection of the most effective measure by predicting the results of an improvement proposed for a particular issue using production simulation software

- A solution realizing a cyber-physical system enabling shop floor information to be used to improve productivity

Conceptual diagram

Case.03

Engineering Design

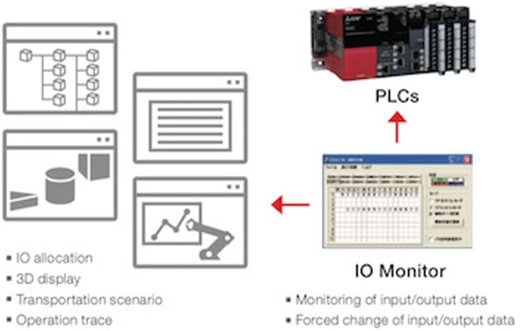

Advance verification of large equipment/device operations using digital mock-up preparation software.

Feature

- Verification with high-speed simulation

- 3D data high-speed display using a light 3D format

- High-speed mechanism simulation and dynamic interference check utilizing Multi-Core

- Simulation with high-speed communications possible through a dedicated connection interface with the PLC

- Concurrent development of equipment/devices possible through connectivity with other software

Conceptual diagram

Case.04

Operation/Maintenance

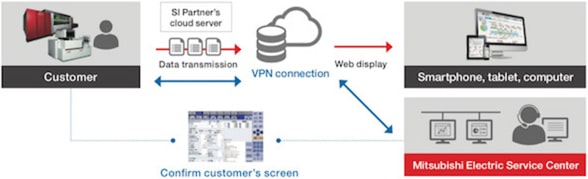

Thanks to the support of our partners, we offer a cloud service for the remote status monitoring and remote maintenance of laser processing machines and electrical-discharge machines.

A remote service supporting the productivity and maintainability of laser processing machines and electrical-discharge machines

- Transfer of machining results and consumable parts information from the processing machine to the cloud server to achieve visualization

- Directly connect and diagnose production equipment remotely during fault occurrence

Dashboard function

- Real-time display of operational information, predicted machining time, etc.

- Collect and accumulate operational results, power/gas consumption, etc.

Contributing to improving production prosses and reducing running costs

Improving maintainability

with a remote diagnosis function

- Remote diagnosis and preventive maintenance of customer’s processing machine from our service center

- Swift response by Mitsubishi Electric personnel when breakdowns occur

- Able to update software versions and change machining conditions from our service center