Human-Machine Interfaces(HMIs)-GOT GT SoftGOT

Solving issues in building systems

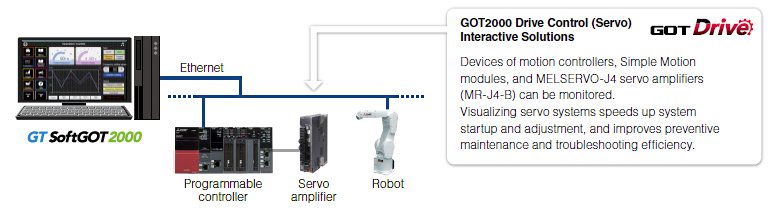

Easy connection between a personal computer and industrial devices at the shop floor

Various communication drivers are supported to enable easy connection of industrial devices

Various industrial devices data can be monitored

GT SoftGOT2000 has various communication drivers as standard.

Just by selecting connection destination in HMI/GOT Screen Design Software GT Works3, industrial devices can be connected.

*For the connectable models and connection types, please refer to the GT SoftGOT2000 Solutions “GT SoftGOT2000 Connectable Model List” .

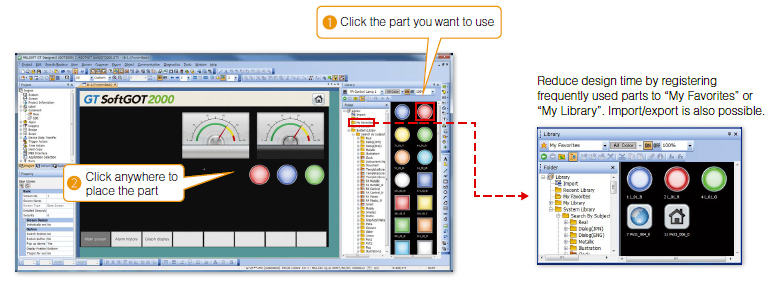

Creating screens easily without excess efforts

Simple operation for beginners enables easy screen creation

HMI/GOT Screen Design Software MELSOFT GT Works3

Using parts is simple. Just select a part and place on the screen! Design your screen with intuitive pick and place operation.

*For the details of GT Works3 functions, please refer to “GT Works3”.

Efficiently create screens with sample screens included in GT Works3

Recommended functions that are often used at shop floor are included in GT Works3 as sample screens.

The sample screens of GOT2000 Series can be used for GT SoftGOT2000 just by changing resolution. Since there is no need to create screens from scratch, screen design work can be reduced.

![Sample screens [English, Japanese, Chinese (Simplified)]](/fa/products/hmi/got/pmerit/sgt/sgt2000/images/solution_02_03.jpg)

*For the details, please contact your local sales office.

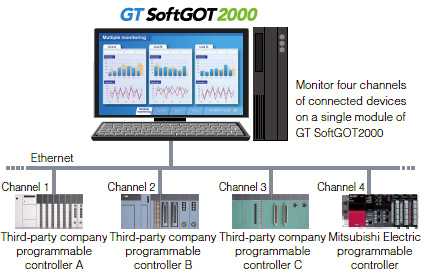

Collectively monitoring programmable controllers of different manufacturers

Programmable controllers from multiple manufacturers can be monitored collectively

Multi-channel connection [NEW]

In multi-channel connection

(GT SoftGOT2000 (Multi-channel)) only

Up to four channels of industrial devices connected by Ethernet connection can be monitored on a single module of GT SoftGOT2000. Since there is no need to create project for each connected device, monitoring multiple devices on one screen increases efficiency in monitoring work and operation.

Collectively monitor multiple lines from an office

Multiple lines can be monitored collectively on a single personal computer

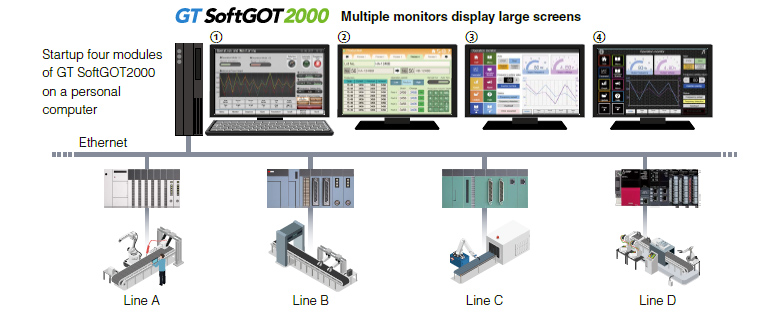

Startup multiple modules

Since multiple modules of GT SoftGOT2000 can be started on a single personal computer, multiple lines can be monitored collectively. By displaying the screen on multiple monitors, the contents can be viewed in larger screens.

Collectively monitor with multi-channel connection [NEW]

In multi-channel connection, multiple lines can be monitored by starting a single module of GT SoftGOT2000 without starting up multiple modules of the software.

Monitoring the information of on-site GOT as is from office personal computer

The same screens as the on-site GOT can be monitored on a personal computer

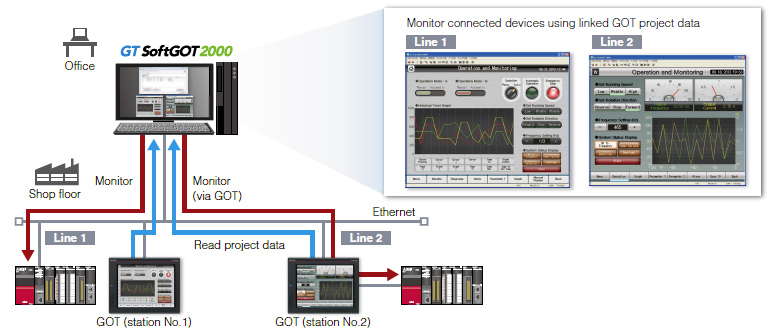

SoftGOT-GOT link function

In single channel connection

(GT SoftGOT2000) only

If GOT is used at the shop floor, GT SoftGOT2000 reads project data from the GOT via Ethernet, and uses the project data to monitor connected devices.

There is no need to create project data dedicated for GT SoftGOT2000 and quick remote monitoring of industrial devices is enabled via Ethernet.

Since GT SoftGOT2000 can also display a different screen from the one shown on the GOT at the shop floor, monitoring on GT SoftGOT2000 does not affect shop floor operation.

In addition, exclusive control of authorization is provided as standard to prevent simultaneous operations and ensure safe operation.

*SoftGOT-GOT link function is supported by GT27 and GT25. Not supported by GT23, GT21, and GS21.

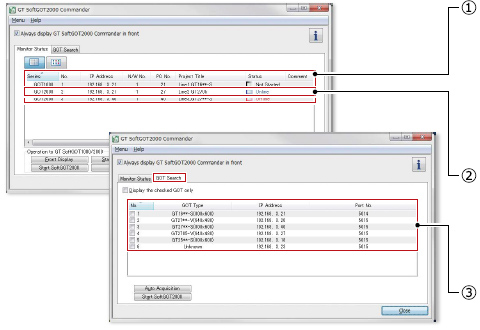

GT SoftGOT2000 Commander makes monitoring work efficient

When using the SoftGOT-GOT link function, GT SoftGOT2000 Commander can be used to collectively check the monitoring status of GT SoftGOT2000 modules, and start or stop monitoring of the modules.

*GT SoftGOT2000 Commander is a software included in GT Works3, the same as GT SoftGOT2000.

①Effective usage when there are multiple GOTs that use the SoftGOT-GOT link function

The list shows which GT SoftGOT2000 module is linked to which GOT, and each monitoring status.

Since it is recommended to use up to four modules of GT SoftGOT2000 online simultaneously, after starting up 20 modules of the software, up to four modules can be set online and thus large-scale systems can be monitored efficiently.

②Managing start/stop of monitoring is easy

Double-click the Comment column of each line to switch between Online and Offline, or between Not started and Online (Offline).

- Online: during monitoring

- Offline: stopped monitoring

③Automatically search for GOTs to monitor

GOTs that can use the SoftGOT-GOT link function can be searched.

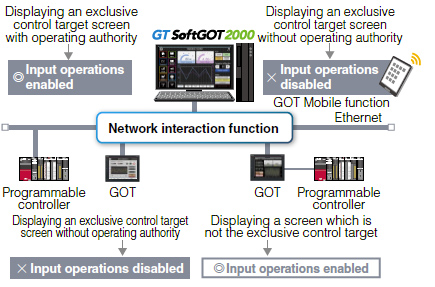

Prevent simultaneous operation by exclusive authorization control with various devices

Network interaction function

Simultaneous operations from GT SoftGOT2000, GOT, and the GOT Mobile function client terminals on the same network can be prohibited. The exclusive control can be enabled/disabled for each screen.

Easily supporting FDA 21 CFR Part 11 of a system

Various functions to support FDA 21 CFR Part 11 are available

Utilizing support functions and sample screens

GT SoftGOT2000 can be used to support FDA 21 CFR Part 11*1, the standards about electronic data recording of the traceability information, which is required in the food and pharmaceutical industries. Sample screens are available for helping you configure systems.*2

- *1The range that GT SoftGOT2000 can support is limited. For the details, please refer to the Technical Bulletin

- *2Sample screens are for use with the GOT2000 Series. To use the sample screens with GT SoftGOT2000, it is required to change the GOT type to GT SoftGOT2000.

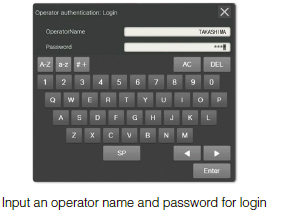

Access management per operator

The operator authentication function enables management of users who can login to GT SoftGOT2000.

Operator authentication function

*To prevent impersonations, user accounts should be managed thoroughly by the users.

Operator authentication screen

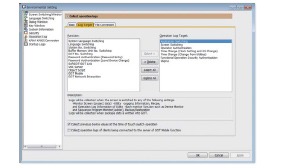

Recording audit trails (histories for the follow-up survey later)

Audit trails can be recorded by setting the operation log appropriately.

Information required to be recorded

- Time stamp

- User name of the logged-in operator

- Description and details of the operation

performed by the operator

(logs before and after the data change)

Operation log target setting screen (GT Designer3)

Sample screens to support configuring systems

Sample screens show setting examples that support FDA 21 CFR Part 11.

*For the details, please contact your local sales office.