Mio Nonaka

SERENDIE – stories

STORIES / INTERVIEW

Solving Thermal Social Issues with EMS Knowledge: Next Steps by Leveraging Our Digital Platform “Serendie”

2024.11.22

Mitsubishi Electric Corporation

Associate Expert, Energy Solution Group, E&F Solution Department

Joined the company in 2006, she has been engaged in research and development on energy and air-conditioning control systems at the Advanced Technology R&D Center within the Corporate Research and Development Group. Appointed to her current position in April 2024, she is responsible for business planning, focusing on comprehensive thermal solutions.

How is Mitsubishi Electric’s digital platform Serendie being utilized in its solutions and services? In this article, we take a closer look at a case study on “Heat-Related Total Solutions” announced by Mitsubishi Electric Corporation in May 2024, which offers one-stop support for optimizing the use of electricity and heat. Mio Nonaka of Mitsubishi Electric’s E&F Solution Department, which promotes heat-related total solutions, discusses the value and potential of Serendie.

Expertise in Electric Energy Management Applied to Thermal Energy Management

——What is the background behind Mitsubishi Electric’s development and provision of heat-related total solutions?

Nonaka Mitsubishi Electric has a lot of experience in providing electrical equipment and energy management systems (EMS). We also manufacture heat-generating equipment such as air-conditioning and hot water supply systems as well as industrial cooling and heating systems.

Despite having these components, providing a comprehensive solution for both electrical and thermal energy needs was still a work in progress. While the country is moving forward with carbon neutrality incentives to reduce greenhouse gas emissions to virtually zero by 2050, manufacturers, building owners, and heat-supply operators are generating and utilizing a lot of heat, and thus reducing CO2 emissions during heat production has become an issue. Therefore, we wondered if we could apply the energy management technology that Mitsubishi Electric has developed in the electrical field to the heat-related field as well.

——What are the features of your heat-related total solutions?

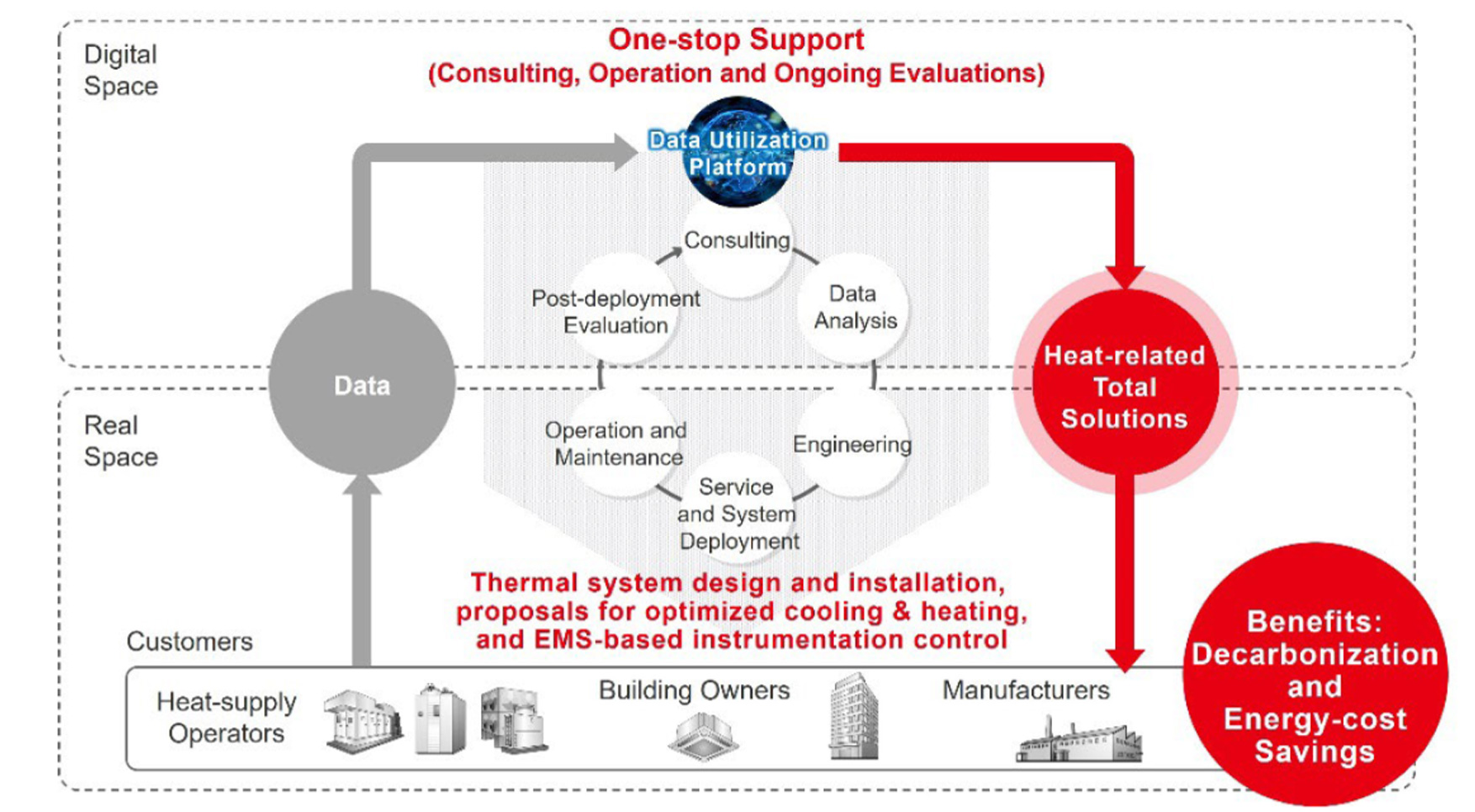

Nonaka We believe that our business has three main characteristics. The first is that we can provide a one-stop service. For heat-related total solutions, we analyze data from the customer’s real space in a digital space and propose equipment replacements and operational improvements. If the proposal is accepted, we can provide seamless support from equipment installation to subsequent operation and maintenance, as well as subsequent re-evaluation.

The second is that we are taking the energy management technology that we have developed in EMS for electricity and applying it to thermal systems. We believe that our strength lies in the fact that we have the technological base and can apply it to solutions for thermal energy management.

The third is support for data scientists and data analysis infrastructure. We feel that the quality and speed of data analysis has improved by working with “Serendie”, the digital platform that Mitsubishi Electric is building.

——Specifically, what kind of ideas and processes do you use to provide solutions?

Nonaka Mitsubishi Electric is committed to transforming itself into a “Circular Digital-Engineering Company”. Our concept is to solve social problems and grow together with our customers through a cycle of gathering data from the customers’ real space, analyzing it in the digital space, proposing improvements, and then gathering and analyzing data again.

We incorporate this concept into our heat-related total solutions. We provide one-stop services that cover consulting for customers’ heat-related issues, designing heat systems and supplying hot and cold water equipment through data analysis, and supporting the efficient operation of electricity and heat energy with EMS.

——What types of industries and business categories do you envision serving? And what kinds of solutions do you plan to offer to address the specific issues in each?

Nonaka Our three main target groups are manufacturers, building owners and heat-supply operators. The issues and approaches vary depending on each customer’s industry and their use of heat.

The manufacturing industry emits a significant amount of CO2 to produce heat. Although there is an understanding of the need to work toward decarbonization, concrete measures are often unclear. First, we conduct data analysis to assess current CO2 emissions and energy usage. If data is not available, we begin by discussing what kind of data should be collected. Then, we examine potential measures to reduce CO2 emissions and evaluate their economic feasibility, taking costs into account.

Building owners and heat-supply operators need to consider additional measures beyond the energy-saving and decarbonization initiatives they have been implementing. Many of our customers have accumulated data on a variety of equipment, which can be utilized to make proposals. For these customers, we believe that our Circular Digital Engineering fits well, as it allows us to gather data and provide new perspectives and solutions.

Heat-Related Total Solutions System

* “Serendie” is the name of the Data Utilization Platform in the digital space.

Utilizing Serendie as an Accessible Data Analysis Platform for Everyone

——What value do you see in Serendie, which also serves as a means to achieve Circular Digital Engineering?

Nonaka In heat-related total solutions, we will operate a circular system in both real and digital spaces.

Mitsubishi Electric has traditionally focused on selling products in the real space. However, our business extends beyond that; our group includes engineering firms and affiliate companies that provide maintenance and operational support after delivery. By leveraging the collective expertise across these group companies, we are able to enhance our support in the real space.

On the other hand, valuable analysis in the digital space becomes possible by leveraging the human resources of the DX Innovation Center (DIC), established in April 2023 as a cross-company organization under the direct control of the President, as well as utilizing our digital platform, Serendie. I believe that our strength lies in our ability to integrate these organizations and expertise, connecting them into a circular network that unites the entire organization.

In addition, we are considering seeking support from external partners for knowledge in areas that Mitsubishi Electric and its group companies currently lack. The E&F Solution Department is promoting business development by exploring which markets and partners will enable us to create better business opportunities.

——Could you provide some specific examples of how you work with Serendie in delivering heat-related total solutions?

Nonaka Actually, the E&F Solution Department and DIC were established around the same time and have been working together for over a year. Our heat-related total solutions are gaining recognition following the announcement in May 2024, and we are now beginning to engage in business discussions with customers. We are seeing an increase in opportunities to receive and analyze data from our customers, and for these cases, we utilize “Dataiku,” a data science tool provided on the data analysis platform of Serendie.

In both the E&F Solution Department, where I work, and DIC, we have data scientists whose high skill levels have significantly improved the quality and speed of our proposals. Dataiku is an easy-to-use tool that helps us leverage their expertise effectively. We have come to recognize that using Dataiku is the best way for us to share and analyze results with other stakeholders involved in the business. It is user-friendly not only for data scientists but also for a wide range of users, allowing us to visualize our data and enhance productivity.

——Aside from that, are there any other tools or features provided by Serendie which you believe could be utilized effectively?

Nonaka With regard to heat-related total solutions, it is essential to combine various types of data. For example, the operation data of air conditioners and heat sources, as well as data on building usage and weather, are stored in different locations, yet they need to be integrated and analyzed comprehensively. We believe that the WebAPI integration platform provided by Serendie will be of great help in such cases. Along with the data utilization platform, we anticipate that this data integration platform will be highly effective.

Enhanced Accuracy in Heat Demand Forecasts Through the Utilization of Serendie

——What do you consider important when collaborating with customers on heat-related total solutions?

Nonaka We are collaborating on joint Proof of Concept (PoC) with our customers, who are heat-supply operators and building owners. We conduct experiments in the customers’ environments, refine the technology based on data analysis and discussions, and then conduct further experiments. In this way, we move back and forth between the real space and the digital space as we advance the PoC. I feel that it is important to exchange knowledge and insights with customers throughout this cycle to enhance our technology and add value.

We are in the process of starting specific discussions with some of our manufacturing customers. We anticipate receiving CO2 emissions reports and inquiries from companies within the supply chain. We need to visualize how much CO2 is being emitted, outline the associated costs, and present scenarios that highlight the benefits of identifying and reducing waste. This approach will lead to the eventual merits they can enjoy.

——Please let us know about any other specific results you have achieved.

Nonaka In PoC with heat-supply operators, we focused on forecasting the demand for heat usage. We collaborated with the customer in a cycle of assessment and improvement by applying various forecasting techniques. In fact, we found that simply using a forecasting technique we initially thought would be effective did not yield sufficiently accurate results in some cases. Therefore, we examined the indicators used for forecasting and adjusted the parameters. At the same time, we sought the customer’s insights and provided feedback through a cycle of analysis using Dataiku. As a result, we were able to considerably improve the accuracy of heat demand forecasts

In our PoC with general contractors, we conducted a demonstration experiments on air-conditioning heat source control for demand response (DR). To achieve the target DR level, we tested several different control patterns to determine the most effective way to manage storage batteries, heat sources, and air-conditioning systems, analyzing the results together with the customer. We are working to enhance our technology by combining the customer’s insights with our own, iteratively refining the control approach and re-testing.

——Finally, what are your future prospects for heat-related total solutions?

Nonaka In the short term, we are currently starting PoCs with several customers, and we believe we need to make decisions on moving toward commercialization within the next few years. In particular, we have just begun discussions with a number of manufacturers, so we will need to establish reliable solutions through a series of future PoCs.

Our long-term goal is to establish the business as a “Circular Digital Engineering Solution” and to build a foundation for scaling it up by leveraging the cycle of heat-related total solutions. We plan to continue our efforts with the aim of expanding the business by around 2030.