World roundup

Competition Between Talented Engineers

― Mitsubishi Electric Cup Automation Contest (MECA)

Published in November 2023

Part 2: The Struggles of Talented Young Engineers – Systems Application Category

The challenge for the finals in the Systems Application category was to assemble a specified processing system within a set time limit. Judges rigorously scored the teams’ ability to enhance the hardware design, software programming, installation and debugging, management and security, as well as other skills needed for business. Twenty-five teams, each made up of three students and supervised by a professor, took on this difficult challenge.

The additional request made their smiles disappear.

On the morning of the finals, July 28, 2023, the competition got underway. The teams were all in a room neatly marked off in small work areas and provided with tools and machinery; there was a three-hour time limit.

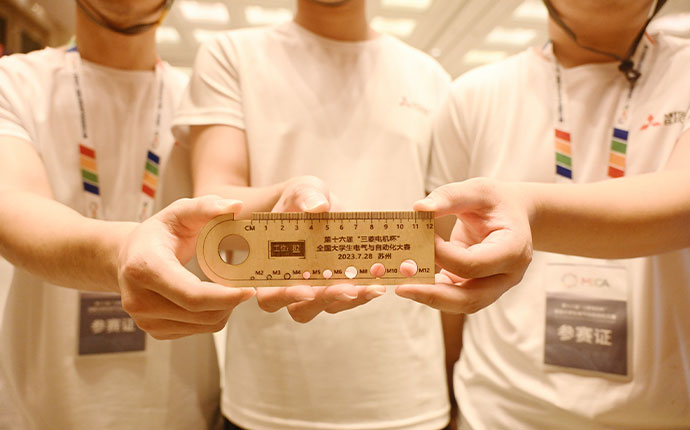

The students all worked on the task of assembling a processing machine that manufactures irregularly shaped rulers, based on a processing sample using Mitsubishi Electric’s FA products. The crux of the challenge was to reproduce a ruler to exactly the same specifications as the sample. As well as producing the machine, the task included the additional challenge of developing a software/interface to reproduce a digital twin*.

* A technology that uses real world data to create synchronized 3D simulations.

With only three hours allowed, the students had to be fully focused on completing the task

In the preliminaries that began in May 2023, participants were asked to write a paper on how to create a processing machine or system to manufacture the processing sample specified by the contest’s judging panel. From this, teams were selected to attend the finals. However, additional information on the processing sample to be produced at the final, such as details for printing and hollowed-out circles were not actually disclosed to the competitors until the day before. (About 20% of the information was additional, according to some participants.) So, on the day of the finals, participants had to redesign the processing system to accommodate the additional requirements, then assemble the processing machine, all within three hours.

To complete the task within the given time frame, familiarity with Mitsubishi Electric’s FA products was a major advantage. Some of the teams were lucky to be from universities where Mitsubishi Electric sponsor a laboratory.

The Liaoning Mechatronics College Team (Entry No. 82) gave some insight into their experience at the finals:

──What was the most difficult part?

It was difficult to do the calculations and programming to turn the circular base of the processing machine so that it cut the right shape.

It was my first time to use digital twin software, so it took me some time to figure it out. And with only three hours, there wasn’t that much time.

──How did the three of you get to know each other?

Although we all major in the same subject, our classes are different, so we did not know each other. We came together after we heard about the competition, and at the finals we have shared the responsibilities, so one of us was in charge of assembly and connection, another programming, and the third HMI design.

Another Liaoning Mechatronics College Team (Entry No. 63) also gave their thoughts

──Was the task of creating a software and 3D simulator difficult?

This was my first time to use this kind of software, so I made the effort to do some research online beforehand and speak to an experienced engineer.

The yellow box in the foreground is the cutting machine.

──Why did you choose the Mitsubishi Electric Cup rather than one of the other robot contests?

There are many robot contests, but the reason why I chose the Mitsubishi Electric Cup is because I use Mitsubishi Electric products at university on a regular basis. One whole floor of our school is a laboratory for Mitsubishi Electric products, such as robot arms and PLCs. There aren’t many products from other manufacturers.

──Are you glad you took part in this contest?

I was nervous at first, but soon fully focused on the task. The opportunity to visit Suzhou also allows me to see some historic sites alongside the high tech industry. I am hoping to compete again next year.

──How did get to know your teammates?

We are all in the same class. We decided to take charge of our own specialist areas, such as machining or programming.

This ruler has exactly the same dimensions as the given sample.

──You have the same school’s name as entry No. 82. Do you all know each other?

We are all in the second year at the same college, so our paths have crossed!

Industry-academia collaboration in China

The two teams that we spoke to were from the same college. So, what does this school think of the Mitsubishi Electric Cup Automation Contest?

According to its website, the school is focused on responding to the needs of national development. Its primary goal is to nurture standards of excellence by upholding the philosophy of promoting teaching, learning and innovation by combining education with competitions.

If hard-working and talented students continue to participate in the Mitsubishi Electric Cup Automation Contest, they can look forward to being hired as work-ready engineers, possibly in Suzhou’s manufacturing industry.

Liaoning Mechatronics College take first prize

Winning first prize in the Systems Application category

On July 28, the finals of the 16th Mitsubishi Electric Cup Automation Contest were held at the Suzhou Taihu International Convention Center. Out of nearly 100 teams from over 60 universities nationwide, two teams made up of students from the automatic control department at Liaoning Mechatronics College won first prize.

Visit the Liaoning Mechatronics College website to learn more:

https://www.lnmec.net.cn/info/1045/6181.htm

In the next section, we report on the Creative Design category, which saw many strong ideas.

- MECA Competition Overview

- Part 1: Contest for Young Engineers Promoted Through Industry-Academia-Government Collaboration

- Part 3: Road to the Best Prize

Which Entry Won the Corporate Special Award? ― Creative Design Category - Part 4: Engineer Interview ― Participating was the Best Decision of my College Life