Solutions

Food & Beverage

Complexity of Production Processes

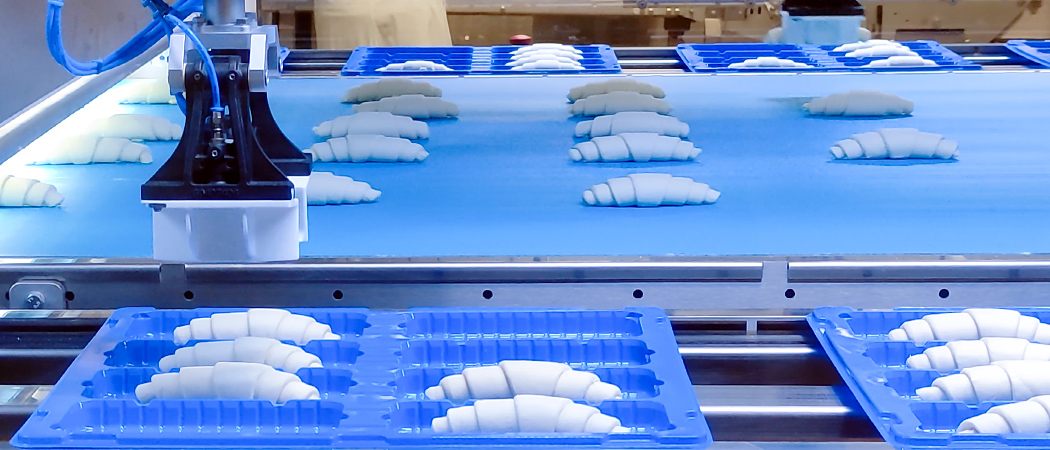

Food and beverage production is one of the most complex processes in manufacturing. It truly is a hybrid industry often mixing multiple elements from process/batch control through to discrete packaging. The challenge is to be able to visualize the entire operation so that decisions can be made in a timely manner and their impact on other elements can be evaluated.

Challenges

-

Challenge 1

Challenge 1How do you see what cannot be seen?

Grasping the operational "picture" in a single glance is one of the challenges of the production manager.

To do this, greater utilization of data networks and SCADA systems is required, even direct integration with the Manufacturing Execution Systems becomes essential. -

Challenge 2

Challenge 2Integration with Legacy Systems

Many food and beverage manufacturers have existing manual or semi-automated systems in place which cannot easily be changed.

There are many challenges to seamlessly integrating new automation technologies with legacy systems. Sometimes they are connectivity based involving networks and protocols, sometimes process based involving digital twins and analysis and even sometimes human based, requiring support and training. -

Challenge 3

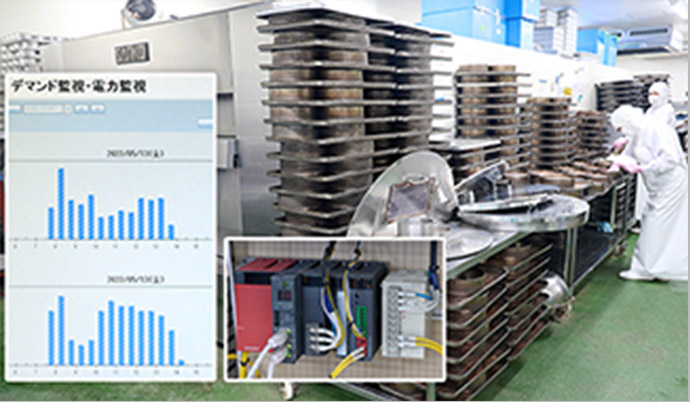

Challenge 3Sustainable manufacturing

Manufacturing sustainability relies on two fundamental aspects. The first is the resilience of the manufacturing process, achieved through efficient maintenance scheduling, proactive monitoring, and streamlined processes, all crucial for optimizing production efficiency and minimizing downtime. The second pillar is energy consumption, which directly impacts operational efficiency and underpins environmental responsibility. Sustainable energy management entails integrating it into automation processes to utilize energy efficiently and judiciously.

Discover the Future of Food & Beverage Automation

Unlock the full potential of automation in the food and beverage industry with our latest thought leadership white paper. From navigating the complexity of production processes to tackling workforce shortages and ensuring regulatory compliance, this essential resource offers actionable insights and innovative solutions to overcome the sector's toughest challenges.

Key Highlights:

- Proven strategies for integrating automation with legacy systems

- Insights into balancing product customization with efficiency

- Best practices for maintaining food safety and hygiene standards

Stay ahead of the curve—download your copy today and start transforming your manufacturing operations!

Register to download here:

Can we ask you

about your experience

using this website today?

Videos

-

Mitsubishi Electric & Malte Schlüter – Interpack 2023

-

Food and Beverage industry: Can cocoa be smart? | Mitsubishi Electric Podcast

-

Digital Journey - with a map | Mitsubishi Electric Podcast

-

N&N Nadratowski: Meat production improvement | Mitsubishi Electric

-

Food safe robotics and 3D vision combine to create the ultimate depositing solution