Solutions

Process Control/

Redundant

Concept

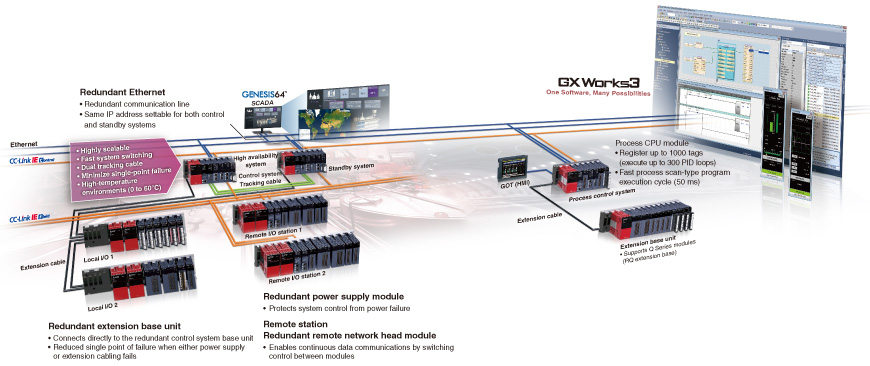

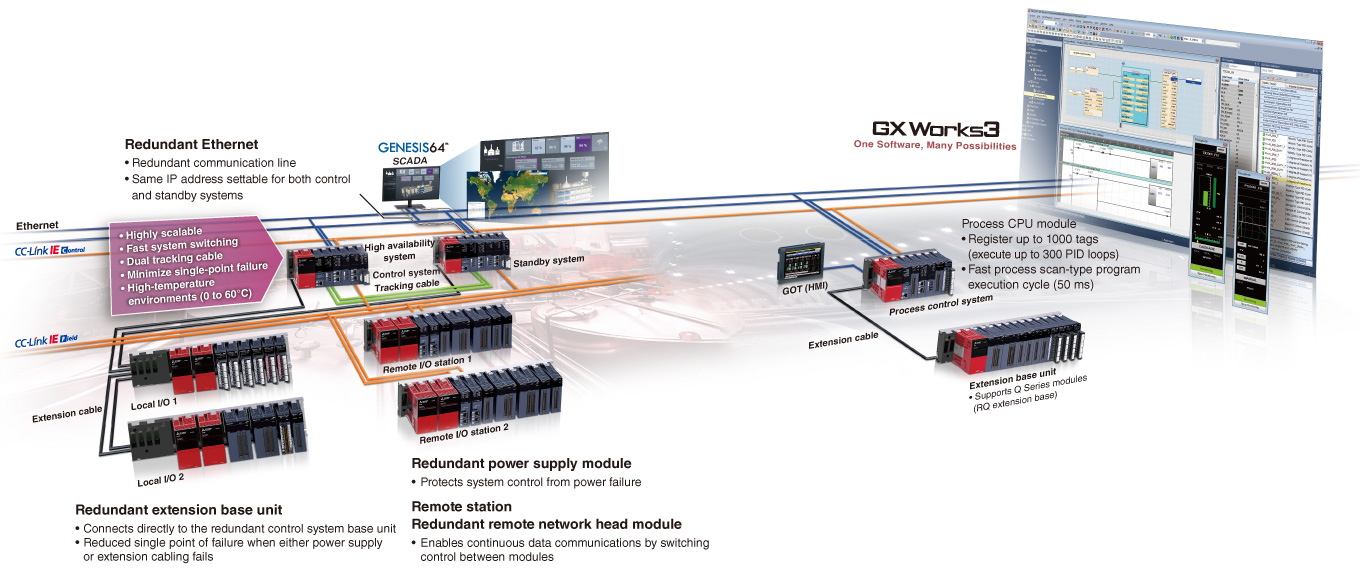

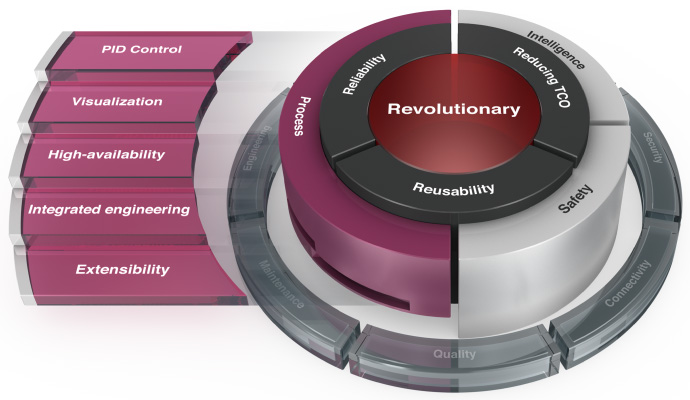

Highly-available process control in a scalable automation solution

The MELSEC process/redundant system is an open and highly flexible general-purpose system, rather than highly-specialized distributed control system (DCS).

Mitsubishi Electric's e-F@ctory solution ensures plant-wide seamless communication via IIoT, optimizing the system through data analysis and utilization.

System monitoring control and data utilization

Extensive visualization

SCADA Software GENESIS64™, GT SoftGOT2000, and GOT2000 provide extensive visualization with their enhanced interconnectivity with the MELSEC iQ-R Series. Advanced features such as energy management, scheduling, alarm and event management, trending, reporting, historian, and Geo-SCADA monitoring realize intuitive factory-wide control.

Multi-level redundancy ensuring continuous control

High availability

Highly reliable control systems can be easily realized minimizing the possibility of single-point failure at the visualization (SCADA), control, network, and extension cable levels, thereby avoiding system downtime and ensuring continuous control and operation of critical systems.

Embedded PID algorithms

PID control

The process CPU includes dedicated algorithms such as two-degree-of-freedom PID, sample PI, and auto-tuning support advanced process control.

One package process control software

Integrated engineering

GX Works3, the standard integrated engineering software for the MELSEC iQ-R Series, makes programming redundant process control systems relatively easy. The program editor uses function block diagram (FBD) language for process control and simplifies system configuration with its intuitive features such as process tag label (variables) sharing, simple program structure, and easy project upload/download to the process CPU.