i4TECH Pte ltd

i4TECH is a leading Systems Integrator in the industry 4.0 space, with deep expertise in MES, IIoT and Advanced Analytics. We help manufacturing companies optimize operations, increase productivity, and adopt data-driven practices to solve real manufacturing challenges in several industry verticals, such as Lifescience, CPG and Discrete manufacturing.

- Address

- 68 CIRCULAR ROAD #02-01 SINGAPORE 049422

- Website

-

https://i4-tech.io/

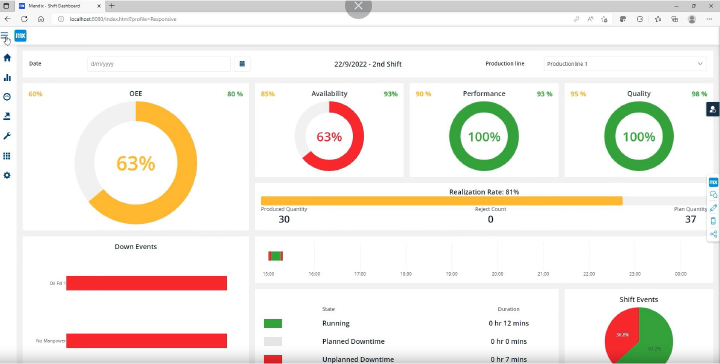

Production Management with O.E.E

Monitor overall equipment effectiveness in real-time to provide manufacturers with the visibility needed to enhance OEE and take proactive measures on the shop floor. Manually collected production data often leads to errors, causing delays and necessitating reactive measures to address bottlenecks that may have occurred hours or days prior. Standard off-the-shelf software frequently fails to align with the specific realities of the shop floor and adds complexity, especially when reconfiguring OEE for different machine lines or during product changeovers. i4TECH's adaptable OEE application enables end-users to rapidly scale across production lines and sites, simplifying complex processes and enhancing operational efficiency.

Our application supports connectivity using standard protocols such as Modbus, OPC UA, and modern lightweight protocols like MQTT.

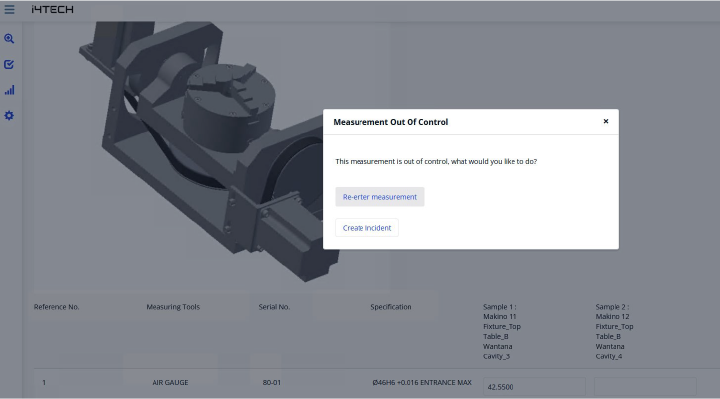

Quality Inspection and SPC

Enhance your quality control processes with i4TECH's versatile application, which facilitates both offline and online quality inspections seamlessly integrated into your manufacturing operations. Our platform delivers comprehensive reports and real-time updates on production quality, empowering your team to promptly identify and address trends that could lead to decreased quality and costly rework. With SPC (Statistical Process Control) charts featuring CP and CPk values, quality engineers receive critical insights to assess whether manufacturing processes are within control limits.

Execute quality inspections flexibly using any computer, tablet, or mobile device to direct operators and gather data directly from the shop floor. Operators can digitally record measurements, conduct sample tests, and route inspection results for approvals. This ensures all operations adhere to stringent engineering standards, maintaining high quality and compliance throughout the production process.

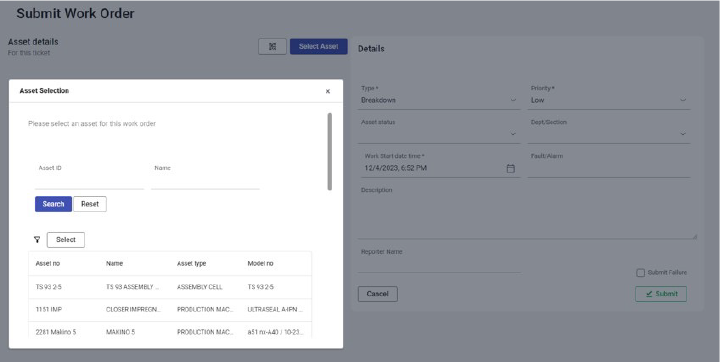

Computerized Maintenance Management System

Streamline your maintenance operations with i4TECH's advanced Computerized Maintenance Management System. This robust platform automates the assignment and scheduling of work orders based on technicians' skills, availability and location. Technicians access a personalized dashboard to view and accept daily tickets, ensuring all necessary information for successful task execution is readily available. Integration with existing ERP systems enables single-entry updates, significantly boosting operational efficiency.

Efficiently register and manage assets, and keep track of essential tools and spare parts to ensure technicians are well-prepared for their tasks. Real-time tracking of asset health and performance KPIs like Mean Time to Repair (MTTR) and Mean Time Between Failures (MTBF) allows for proactive maintenance, repairs, and other critical operations.

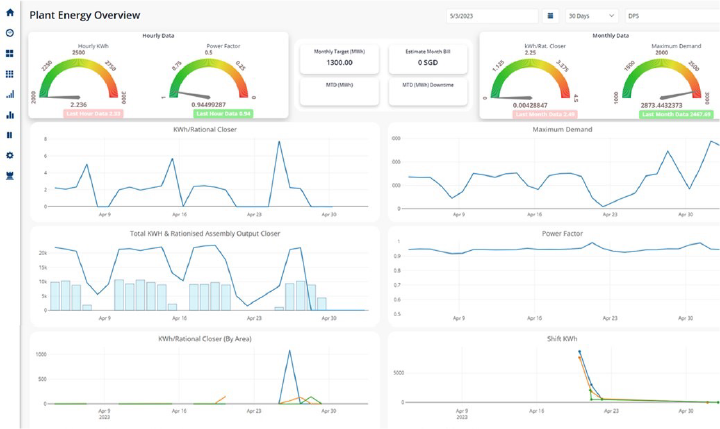

Production Energy Management

Enhance your operational efficiency with i4TECH's intuitive and customizable energy management dashboard, designed to empower energy and production managers to make smarter, data-driven decisions. This tool helps pinpoint energy wastage, reduce costs, boost sustainability, and lower carbon emissions.

Trend Analysis: Monitor consumption trends to understand the behavior of production assets and set performance thresholds tailored to your organization's KPIs.

Energy Optimization: Quickly detect potential energy savings during downtime, minimize wastage from idle machines, and manage peak load conditions to optimize energy use.

Comprehensive Integration: Seamlessly incorporate real-time data from a variety of sources, including power meters, CO2 sensors, air quality monitors, production data, and Building Management Systems (BMS).

This system provides the tools needed to not only manage but also transform how energy is used in your production environment for enhanced efficiency and sustainability

Material and Warehouse Management

Manage your production related warehouse management. business processes from material requests to inventory management in one interface.

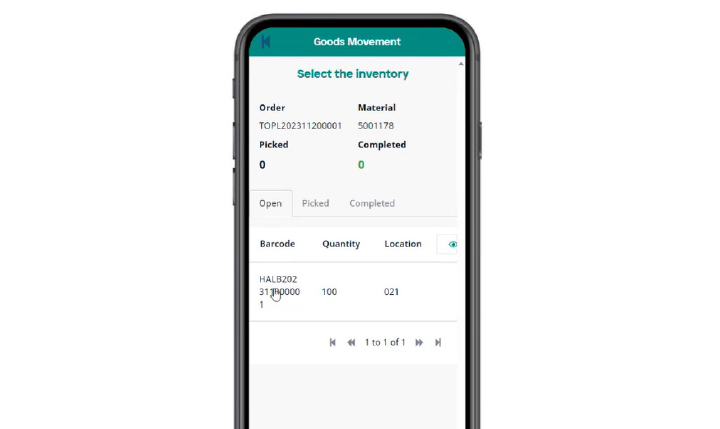

Streamlined Operations: The Smart Warehousing app enhances essential activities such as order requests, picking, and inventory management. It includes mobile applications designed for efficient inventory checks and optimized picking processes.

Seamless Integration: Easily connect to a wide range of warehouse devices and peripherals, including barcode readers and RFID systems, to ensure smooth and continuous operations.

This system not only simplifies warehouse management but also significantly improves operational efficiency and flexibility.

Recipe Management with Production Execution

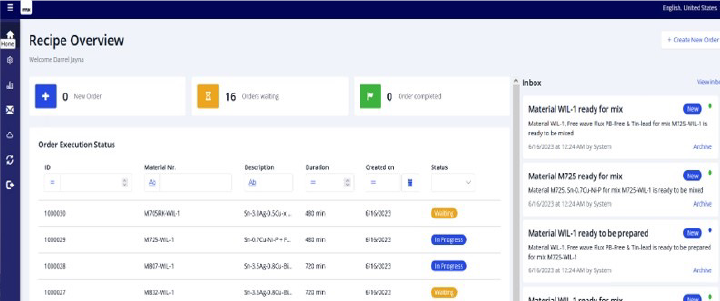

Effortlessly create and customize recipes to meet the specific requirements of various orders. Adjust ingredient quantities and processing steps to cater to different batch sizes and customer needs.

Monitor the consumption of raw materials in real-time, ensuring accurate inventory tracking. Receive automated alerts for materials nearing their expiration dates to prevent the use of expired ingredients and maintain product quality.

Generate comprehensive batch reports that provide detailed insights into each production run. Track yields, quality metrics, and any deviations from the standard recipes to ensure consistent product quality.

Utilize OPC UA protocols to transfer precise recipe parameters directly to production machinery. This integration ensures accurate execution of recipes and enhances production efficiency.

Manufacturing Execution Systems

Implementing MES software from leading MES venfors for discrete, pharamacutical and consumer packaged goods industry

Industrial Data Ops

Implementing DataOps solution from leading platform vendors to provide high quality data for analytics, visualization and application workflows. This includes machine connectivity and data collection, data processing and data contextualization and IT-OT data integration.

Industry 4.0 Application development

Ideation of use cases, prototyping, development, deployment and support of Industry 4.0 software applications, covering the entire value chain from supply chain to production.

Advanced Analytics and Generative AI deployments

Ideation of use cases, prototyping, development, deployment and support of data-driven use cases, such as process optimization, advanced process control, predictive and prescriptive analytics for industrial applications. This includes the adoption of LLM models for Generative AI applications.

Advanced Analytics, Artificial Intelligence and Generative AI services

Engaging a team of highly specialiced data scientics and domain experts, providing machine learning expertise from ML algorithm development, model training and deployment to Large Languge Model application development.

MES consulting and functional expertise

Team of MES domain experts to help clients define functional requirements, develop MES roadmap and Solution architectures. Implement and Validate MES solution and advise on MES enhancements and changes to optimize MES running currently in production.

IIOT consulting and functional expertise

Industrial Automation & OT Specialists and Data Engineers to provide comprehensive OT site assemement and machine connectivity capabilties. We provide cybersecurity risk and gap assesment as per NIST/IEC regulations and technical guidance on developing scalalable solution architectures for smart manufacturing systems on premise, cloud or hybrid.