FOCA TECHNOLOGY CO., LTD.

FOCA Technology Company is an industrial machine builder in Thailand, focused on providing services in automation technology.

We can supply standard or customized solutions based on customer requirements in the semiconductor industry

- Address

- 42/46 Moo 8 Tambol.Klongsong, Amphoe.Klongluang, Pathumthani 12120. Thailand.

Strip Fully Auto Laser Marking System

Key Features:

- Magazine loader/unloader to support max. 4 mag.

- Full auto conversion via recipe programming.

- Support max frame size L300xW100 mm.

- High speed and Accuracy by indexing.

- Frame Orientation by vision inspection.

- Fiber laser marker with dual head.

- Post-marking vision inspection.

- Vision alignment and compensate as optional.

- Easy maintenance and user-friendly interface.

- PC based control and EtherCAT communication

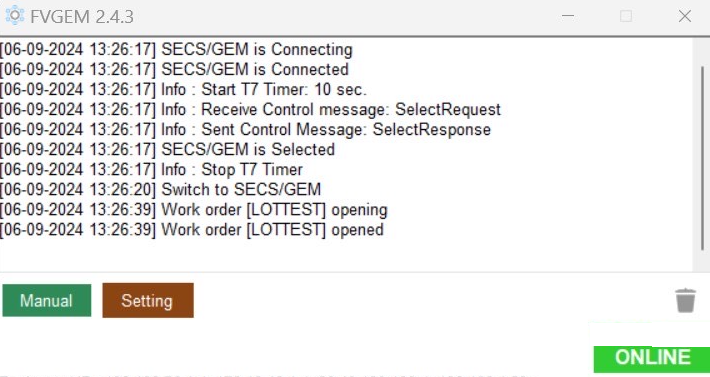

- SECS/GEM compatible.

Reel to Reel Inspection and Sorter system

Key Features:

- Vision Inspect Missing, Wrong orientations and lead etc.

- Defect visualization and reels mapping.

- Precise and high-speed device counter and sorter.

- Alarm and treatment.

- Host reel eMap interface.

- Images logging, result report and recipe management.

- Compact size and ergonomics design.

- SECS/GEM compatible

JEDEC Tray Sorter Machine

Key Features:

- JEDEC Tray autoloader/unloader/empty stacked

- Auto PnP device sorter from tray to tray

- AOI pre-sorter by vision system

- AOI post-sorter by final vision inspection

- High UPH by linear servo.

- Repeatability < 10 micron

- 2D packages sorter available.

- SECS/GEM compatible

3rd Optical Inspection System

Key Features:

- Hands free of lead frame handling

- Top view inspection 2 optional via microscope and CCD cameras.

- Dual side view inspection.

- Fully automated conversion and can programmable frame handling system

- Jam-frame elimination seamless design and force sensor detection.

- Production recipe management system.

- Compact machine and ergonomic design offers comfort working to operator.

- Lead frame package family of SO, DIP, TSSOP and QFN.

- Laser cut wire on defect unit identification as optional.

- SECS/GEM compatible and eStrip mapping system.

Wafer Ring Autoloader Inspection System

Key Features:

- Single Cassette autoloader/unloader.

- Support optical inspection via high microscope and CCD camera.

- Fully auto wafer handling system and can be programmable via recipe.

- Inspection working area support wafer size 6”and 8”

- Motorize objective lens 4 ranges (Zoom: 25x,50x,100x and 200x)

- Anti-vibration machine structure design

- Wafer lot/ID map download/unload via SECS/GEM compatible.