DER PIONIERS COMPANY LIMITED

Formerly an 7 years of experience automation engineering team specializing in providing solutions for process automation control (PLC,DCS,SCADA) together with a local Mechanical team that have more than 30 years of experience specializing in manufacturing and processing stainless steel equipment in the Beer, Dairy, and Wastewater Treatment industries. We founded DerP with the ambition to provide comprehensive solutions in the areas of factory automation and process control. Although the journey is not long, we are proud to have contributed our capabilities to the development of the Automation and Process Control industry in Vietnam. We are proud to have contributed our wisdom and energy to many projects of our customers in many fields of production, contributing to increasing the productivity as well as the value of our customers' products.

- Address

- L17-11, 17th Floor, Vincom Center Building, 72 Le Thanh Ton Street, Ben Nghe Ward, District 1, Ho Chi Minh City, Vietnam

- Website

-

https://derpioniers.com/company

Stainless-steel Tanks

Install storage tanks and pipelines to transfer liquid to the packaging lines.

Install mixers, silos, and pipelines for processes such as dosing, CIP (clean-in-place), heat exchange, etc.

Stainless steel is easy to clean and maintain, making it ideal for food and pharmaceutical applications. It can withstand high and low temperatures, depending on the specific grade of stainless steel.

Stainless-steel Tanks

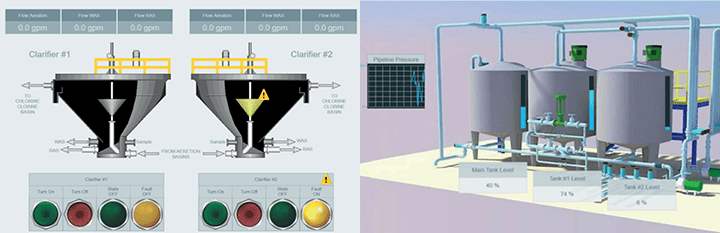

We provide comprehensive solutions in the field of wastewater treatment, beer, food and beverage.

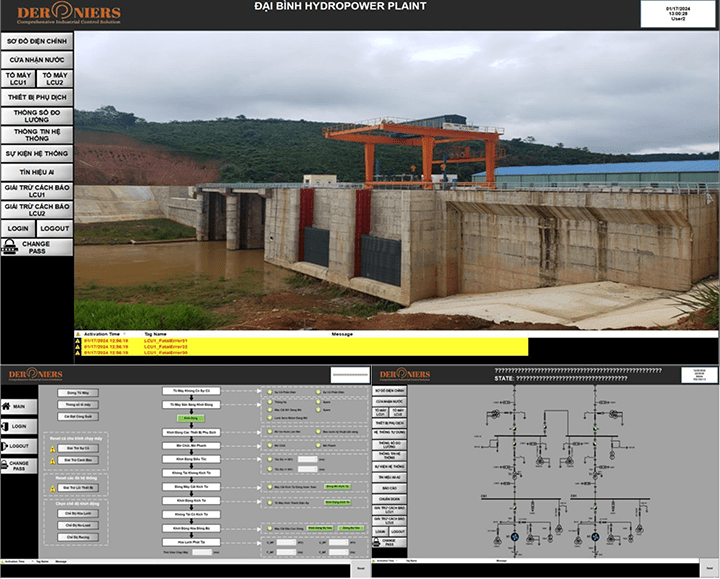

SCADA for Dai Binh Hydro Power Plant

Hydroelectric plant monitoring and control system

Factory utility management system

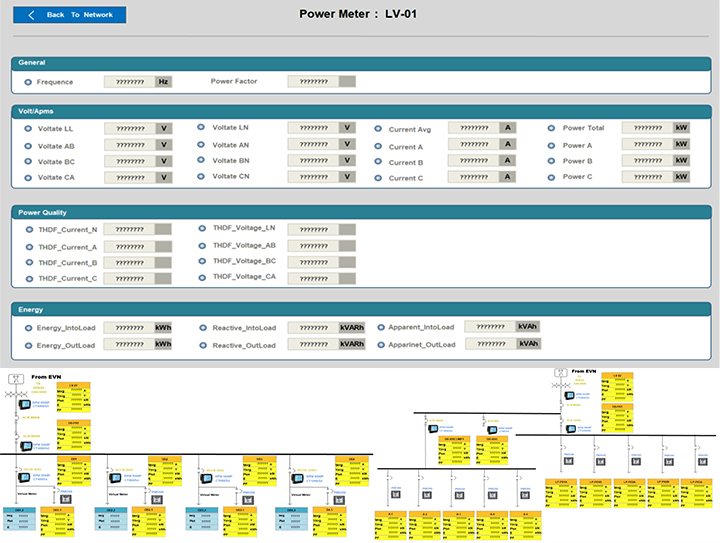

Power management system

Building management system

Systems continuously collect data from power meters installed at different points in the power grid. This data includes parameters such as voltage, current, power factor, frequency, and energy consumption. These parameters are usually displayed in real-time on the SCADA interface. Engineers and operators can monitor these parameters to ensure that the power system is operating within safe limits and to detect any abnormalities or faults

Installation and repair service

Machine equipment and programming services

PLC programming service

Robot programming service