ViSCO Technologies (Thailand) Co., Ltd.

We are an expert group in the field of visual inspections and machine vision system. We are not just a manufacturer. Instead, we are a visual inspection and machine vision system manufacturer that combines knowledge of and experience related to image processing algorithms, optical technology, electronics, and machinery in order to provide comprehensive consulting as a development engineering company.

- Address

- 54 BB Building 13th floor,Room1313, Sukhumvit21Road(Asoke),

Klongtoey-Nua, Wattana, Bangkok, 10110,THAILAND

VTV-9000mini

The VTV-9000mini is a small housing model of the VTV-9000 machine vision system, supporting from 0.3M camera up to 65M, and also offers a high-speed image acquisition model.

< Model Lineup >

- Standard 4 camera model

- High-speed capture 2 camera model

Super Focusing Cameras 12MP Monochrome

By imaging from an angle, defects such as scratches and dents can be seen more clearly.

However, if the image is taken from an angle with a standard camera in the manner of a visual inspection, the captured image will only be partially in focus, making it unsuitable for inspection.

The "Super Focusing camera" is a solution to this problem.

In addition to realizing high-precision inspection, it also contributes to cost reduction at the inspection site.

VTV-QCS / VDA

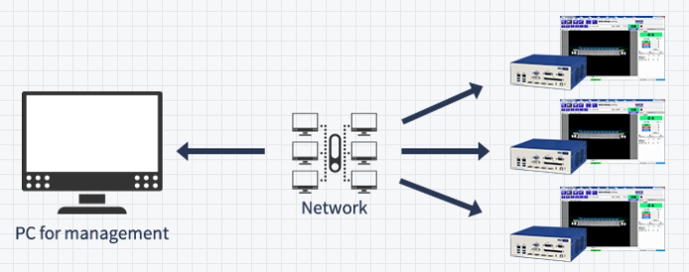

VTV-QCS is software that can be used to check the VTV-9000 operation status or unify the management of inspection data through a PC via LAN

even when you are not on-site at the FA line.

VDA (ViSCO data analyzer) is a monitoring software tool that is used to make charts (graphs) of the inspection results of a VTV-9000 system connected to a network in real time.

Training

Even after our products are purchased, to ensure the possibility of problem-free operation at the inspection site, we provide private training customized for each customer, including everyone from first-time to experienced users.

Currently, web-based training is also available.