Simulation tools MELSOFT Gemini

Usages of 3D Simulator MELSOFT Gemini

3D Simulator has a variety of different usages.

Method1

Production design

To build a line with high productivity

Line layout verification

Able to verify and visualize productivity before actual operation

Possible to build a line with high productivity!

Method2

Machine design

To prevent rework due to miscommunication between machine design and control design

Machine specification verification

Able to create models for simulation from 3DCAD and share machine operations in animation form

Significant reduction of labor time for rework and better DR efficiency!

Method3

Pre-adjustment/ confirmation

On-site machine adjustment takes an exponential amount of time and start-up is significantly delayed

Control program verification

Able to verify mechanical operations in a digital space in advance using a control program

Shorter on-site adjustment period!

Method4

Service & maintenance

To swiftly recover from equipment faults

Problem verification

Able to reproduce the status of lines and machines remotely

Swift shop floor recovery is possible!

Method5

Sales

To convey the value of the equipment we make to customers

Communication support

Able to show how products work in various forms (3D, VR, animation)

Smooth mutual understanding and speedy business talks!

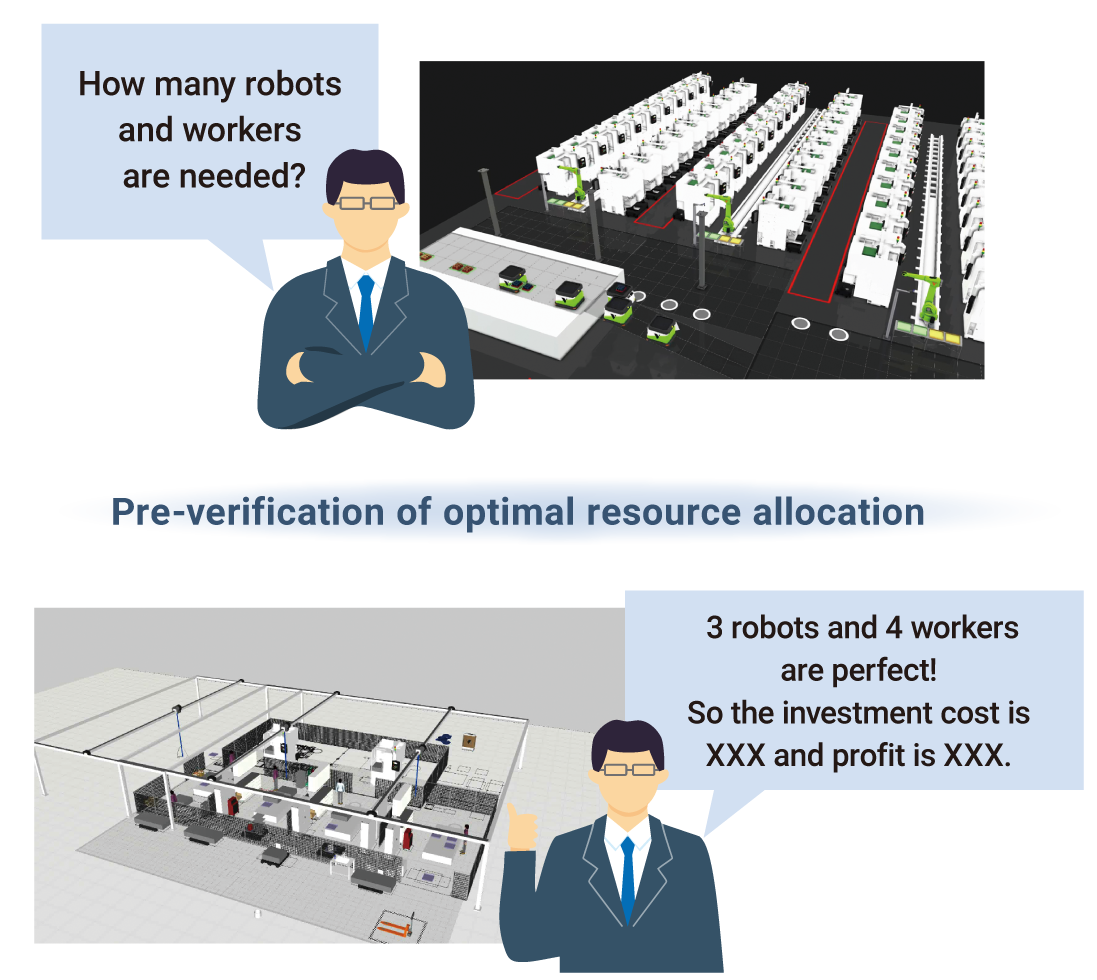

Method6

Management

To increase return-on-investment (ROI) when installing new production equipment or expanding

Support for trial calculation of investment cost for equipment/workers

Able to trial calculate investment cost required for equipment and workers based on simulation results

Optimal investment is possible!

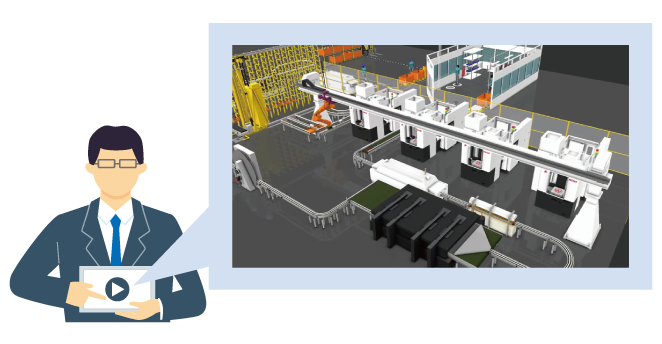

Utilization Method 1

Line layout verification

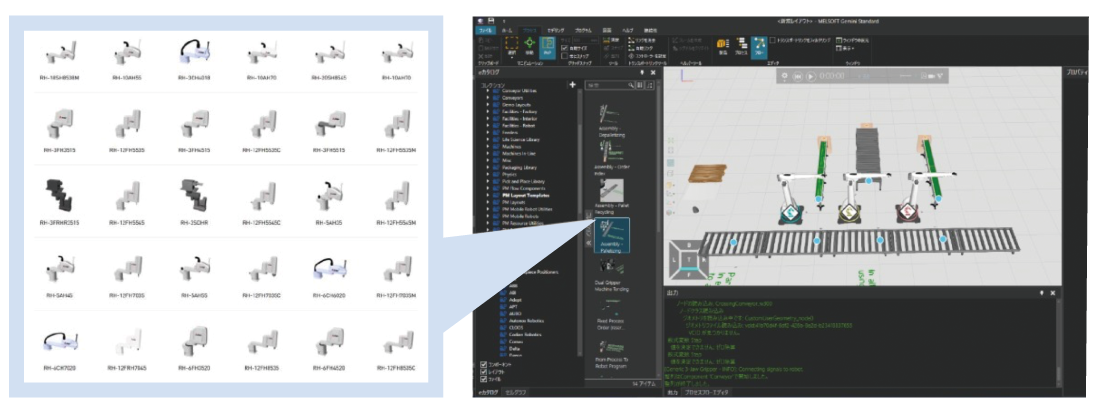

Build & verify layouts from the eCatalog

Layouts can be built and verified by simply dragging and dropping the necessary parts for line verification from the library and performing easy settings. Components that can be used in eCatalog

Visualize & analyze using a chart/statistics function

Simulation results can be visualized and analyzed to identify bottlenecks and changes in operating ratio.

Productive line set up and verification is made easy through arranging models

from an abundant eCatalog and utilizing a statistical analysis function

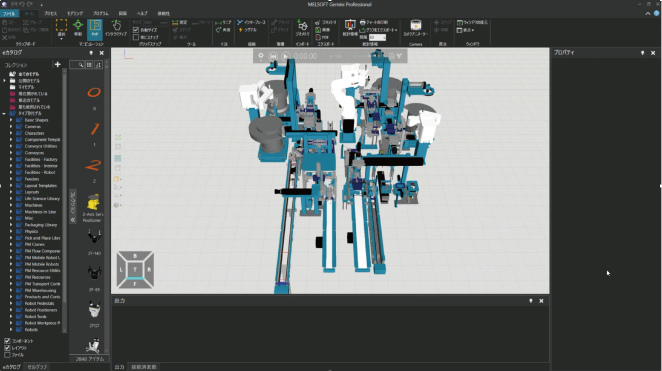

Utilization Method 2

Machine Specification Verification

Operations can be set up by importing 3DCAD data, setting up the mechanism, then using the script in MELSOFT Gemini. This makes it possible to create and simulate machine operations even if ladders and other programming are incomplete. This streamlines the task of alignment conventionally using 2D drawings and timing charts.

"Significant reduction of labor time for rework" is possible

by sharing machine operations and reducing miscommunication between designers

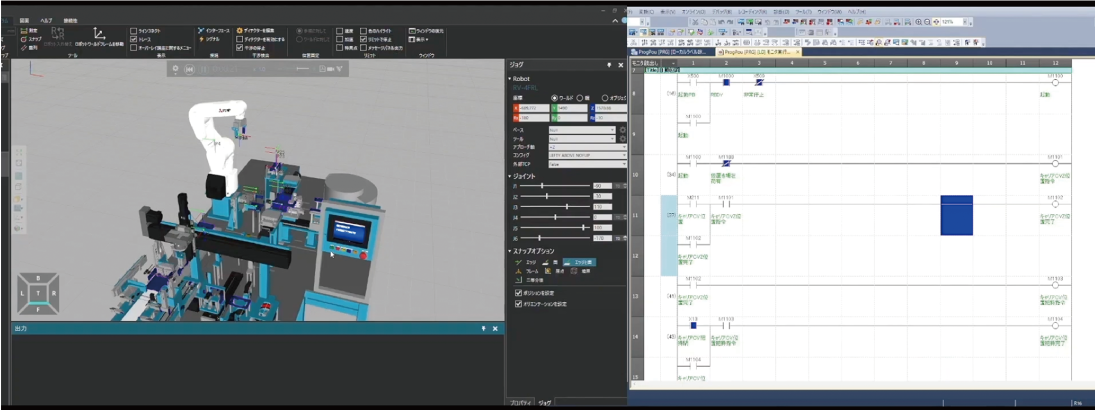

Utilization Method 3

Control program verification

Direct connection to various simulators and FA equipment made by Mitsubishi Electric improves the accuracy of mechanical collision checks. Through connection to other companies’ equipment and simulators via an OPC Server, control logic verification is possible regardless of the equipment or machine.

"Reduced on-site adjustment time" by improving

the level of control logic completeness beforehand

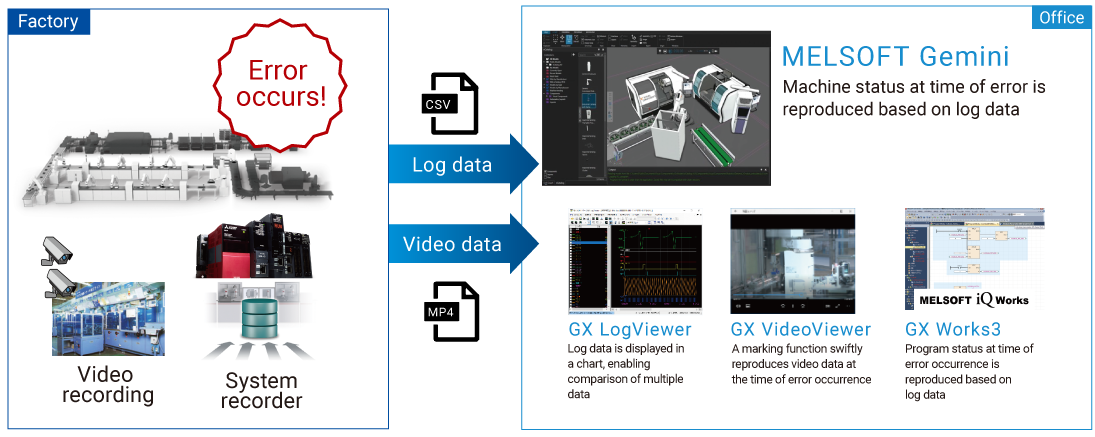

Utilization Method 4

Problem verification

Status at time of error is reproduced as a 3D model based on log data.

Swifter troubleshooting is possible by combining ladder monitor display, waveform display, and image data display.

Equipment operations can be reproduced in. MELSOFT Gemini based on log data and troubleshooting can be performed remotely,

thereby making early shop floor recovery possible

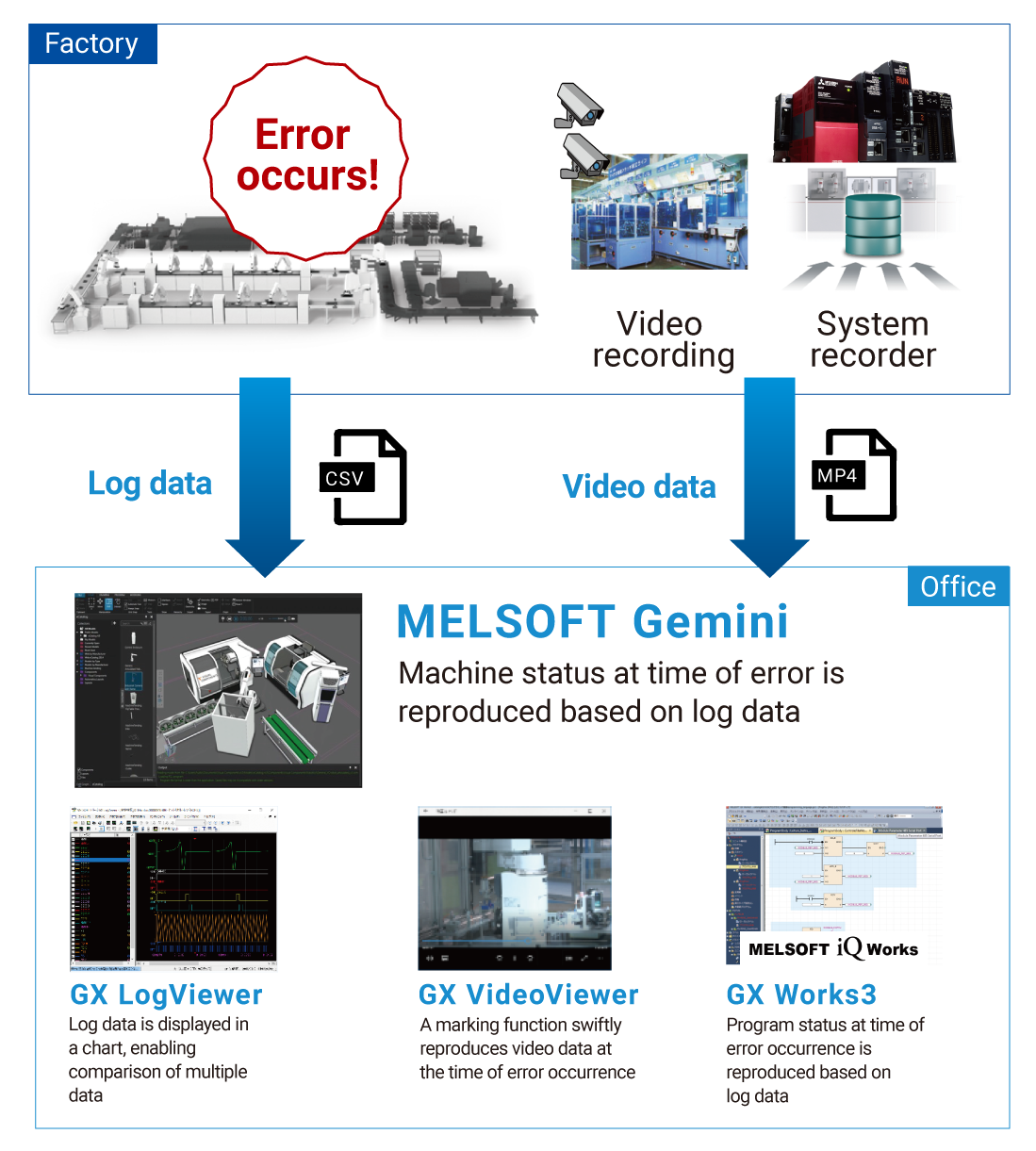

Utilization Method 5

Communication support

When proposing machines and systems developed in-house to customers, by showing them how products work on 3D Simulator, information can be shared without misunderstanding.

"Smooth mutual understanding and speedy business talks" are

possible by showing how products work in various forms (3D, VR, animation)

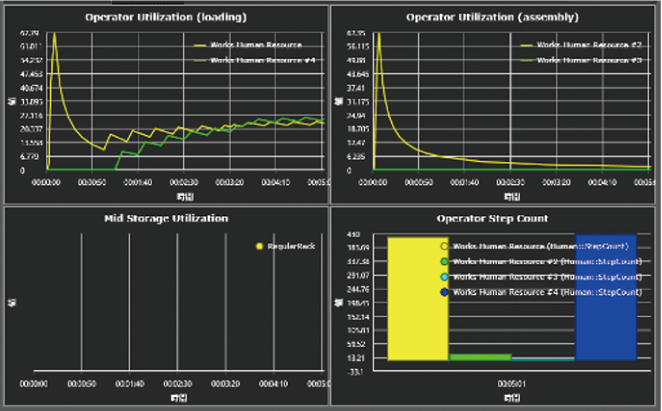

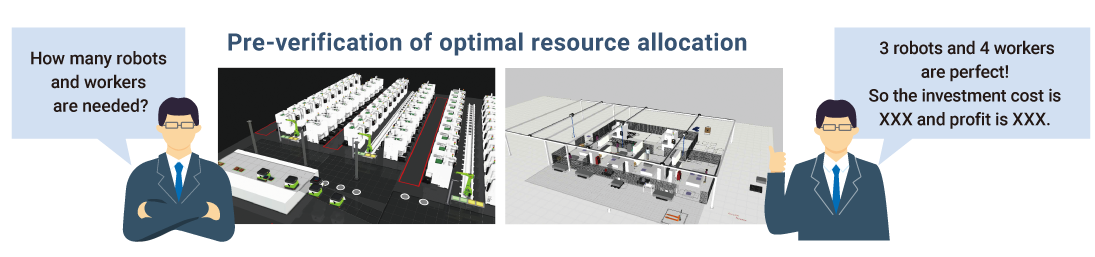

Utilization Method 6

Support for Trial Calculation of Investment Cost for Equipment/Workers

When installing new production equipment or expanding existing lines, verification via simulation of multiple patterns makes it possible to grasp the necessary number of robots, processing machines and AGVs, as well as the necessary number of workers, thus enabling the trial calculation of optimal investment cost.

Optimal investment is possible! by trial calculating investment cost required for

equipment and workers based on simulation results