Products

MELSOFT VIXIO

MELSOFT VIXIO application examples

Here are some application examples of MELSOFT VIXIO.

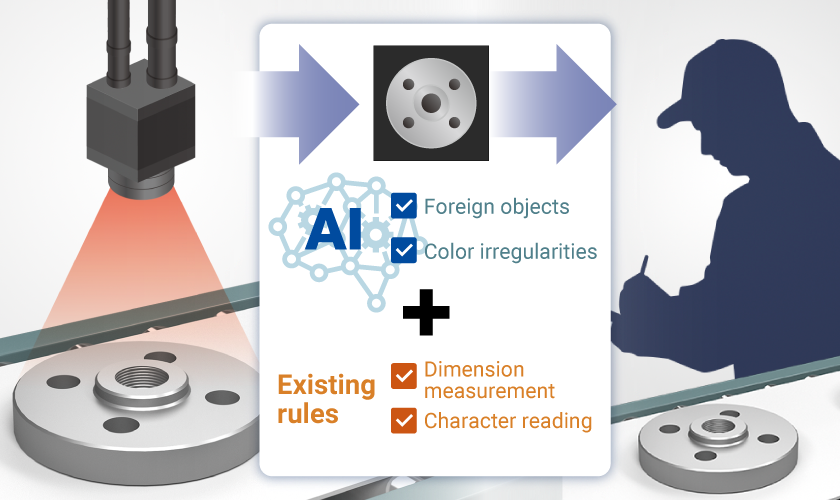

CASE1

Combination of rule-based and AI-based inspections improves the accuracy of the inspection process

Before

Rule-based-only inspection

When rule-based inspection is applied to items for which rules are difficult to define, numerous mis-detections occur.

After

Combination of rule-based and AI-based inspections

Introducing MELSOFT VIXIO AI inspection and using it together with existing rule-based inspection improves inspection accuracy.

CASE2

AI replaces primary screening by human eyes, reducing time and equalizing inspection quiality

Before

Sorting by human eyes and detailed inspection of defective products

Products identified as “possible defectives” by human eyes in the primary sorting must be also checked by the person in charge of quality assurance, which requires task labor.

After

Perform primary screening with AI

Checking products identified in primary screening based on AI judgment results (heat map) reduces task labor.

CASE3

Reduce inspector workload by combining human and AI inspection

Before

Visual inspection process (by human eyes) by only one person

One person in charge of inspection visually checks all products, which leads to overlooking of defective products due to heavy workload.

After

Double check by AI and human eyes

The introduction of double-checking reduces the risk of overlooking defective products and ensures consistency of quality between operators.