Products

MELSOFT VIXIO

What is MELSOFT VIXIO?

MELSOFT VIXIO is a visual inspection software that allows users to use AI without any specialized knowledge.

Concerns in the inspection process

- Labor shortages increase the burden on inspectors

- Generational changes in inspectors make consistent visual inspection difficult

- Even though inspection is rule-based, overdetection is increasing

It would be good to introduce AI if it wasn’t so difficult to start without specialized knowledge.

The solution -

Visual Inspection Software

Featuring a high-speed, high-precision AI algorithm ideal for factory automation

AI introduction challenge

The limited number of defective product images complicates accuracy improvement. Generating AI models requires extensive image learning, making the process time consuming and inefficient.

With MELSOFT VIXIO

Easily generate AI models with high-speed, high-accuracy AI.

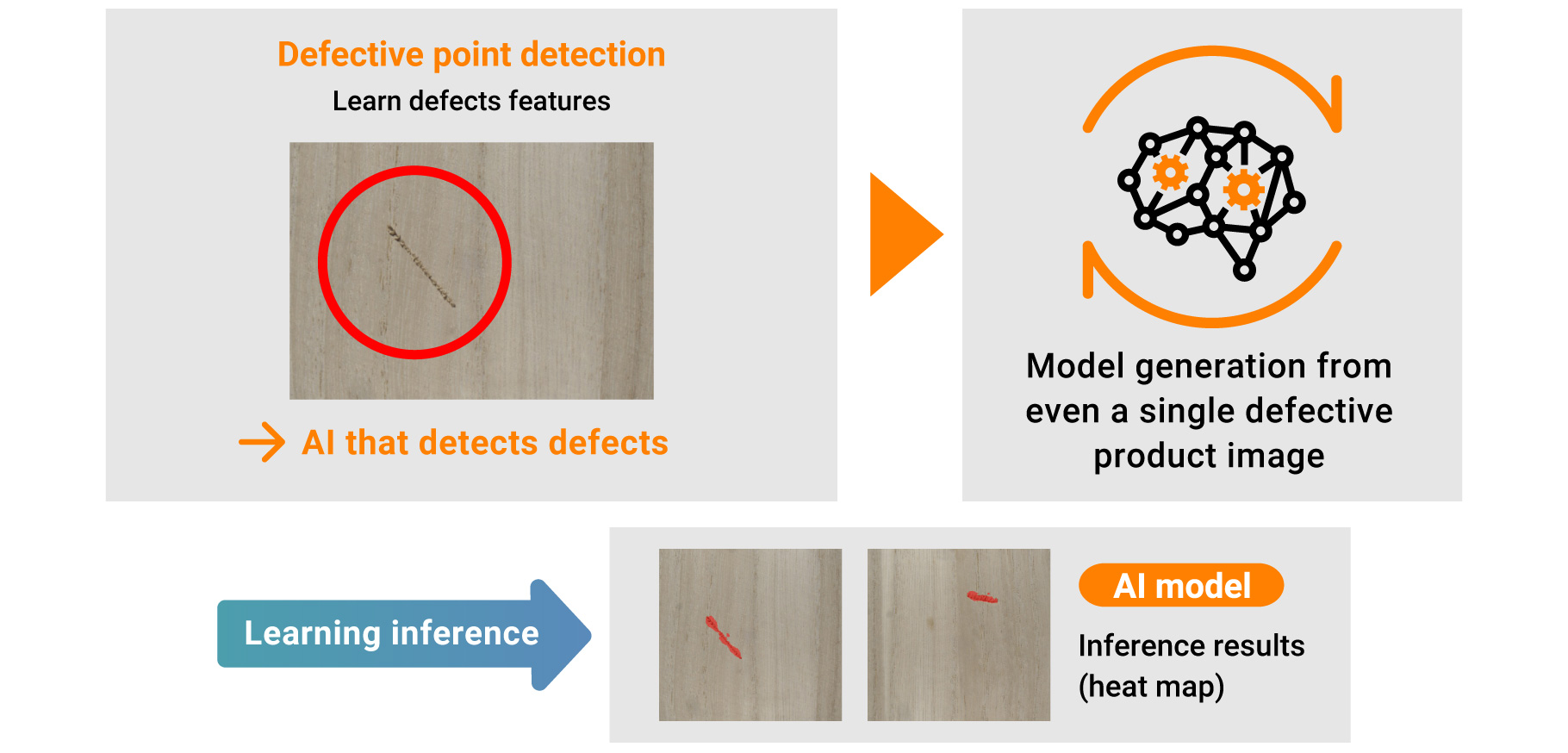

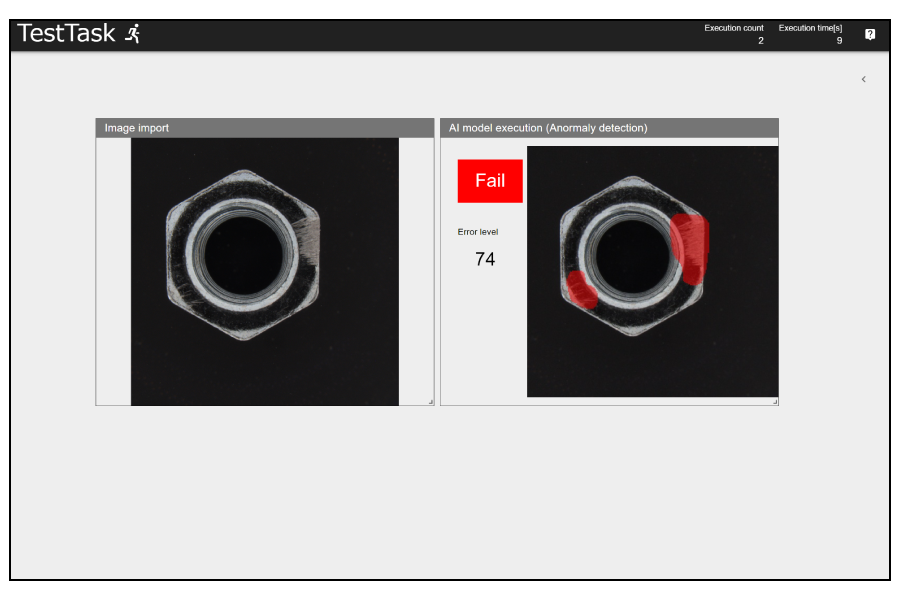

Anomaly detection

Detect “Different from usual”

Point

Even unexpected defects can be detected.

Defective point

detection

Detect specific abnormality patterns

Point

Detection of similar defects even in different locations or with different sizes is possible.

Simple operation settings without programming

AI introduction challenge

Even if an AI model could be generated, specialized programming is required to implement it in the system.

With MELSOFT VIXIO

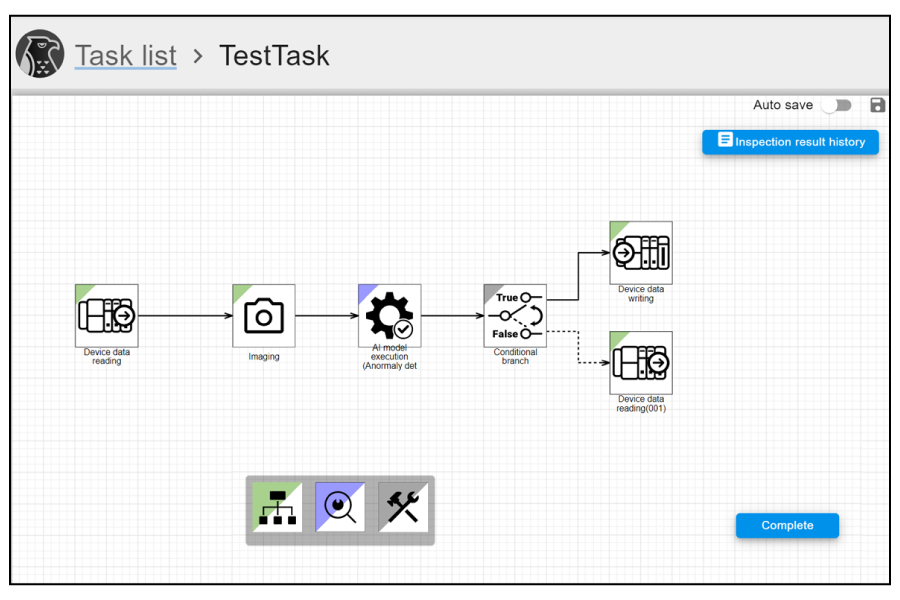

Easily set up tasks in a flowchart format. Settings from model generation to monitor screen creation can be performed with a single tool.

Easy system construction

All functions necessary to construct an AI visual inspection system can be easily set up without programming.

Setting the overall operation

Point

Set the overall operation flow in a flowchart format.

Camera settings

Point

GigE Vision® Area Scan Camera settings can be configured in the camera’s various settings.

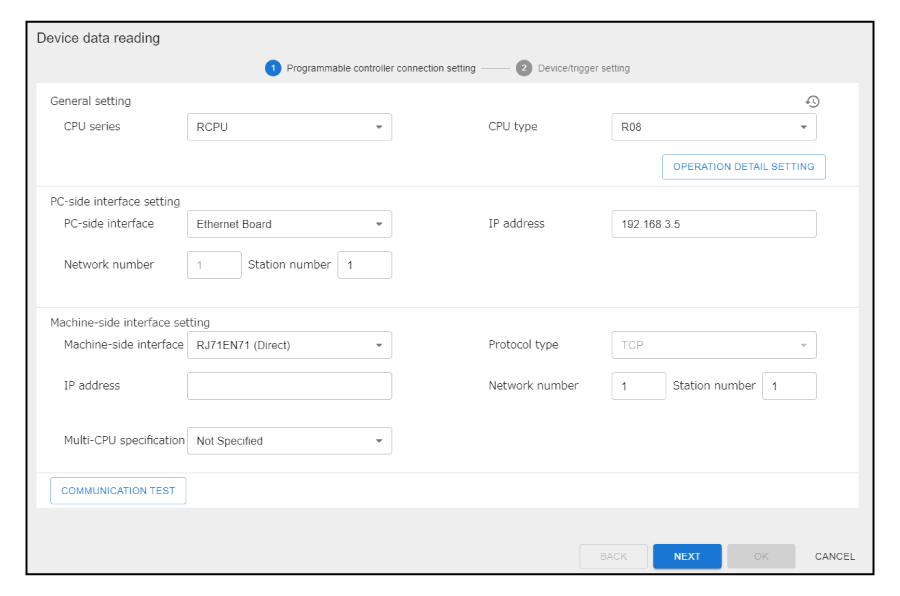

Settings for communication with programmable controllers

Point

Easy data exchange with various programmable controllers

Inspection monitor screen

Point

A monitor screen can be created by arranging the display elements of multiple monitors in a dashboard format.

Improved traceability

AI introduction challenge

Ensuring traceability is difficult because different types of data are saved using separate tools.

With MELSOFT VIXIO

Inspection date/time, programmable controller data, captured image, and inspection results are automatically linked and saved together in a group, for easy traceability.

Automatic linking and traceability

Data handled in inspection tasks can be easily linked and saved together in a batch.

Point

After creating an inspection task flow, simply select the data to save. Various programmable controller data such as manufacturing information, inspection results, and captured images can be automatically saved when the task is executed.