FA Application Package Rotary Machine Vibration Diagnosis

Terminology of the vibration analysis

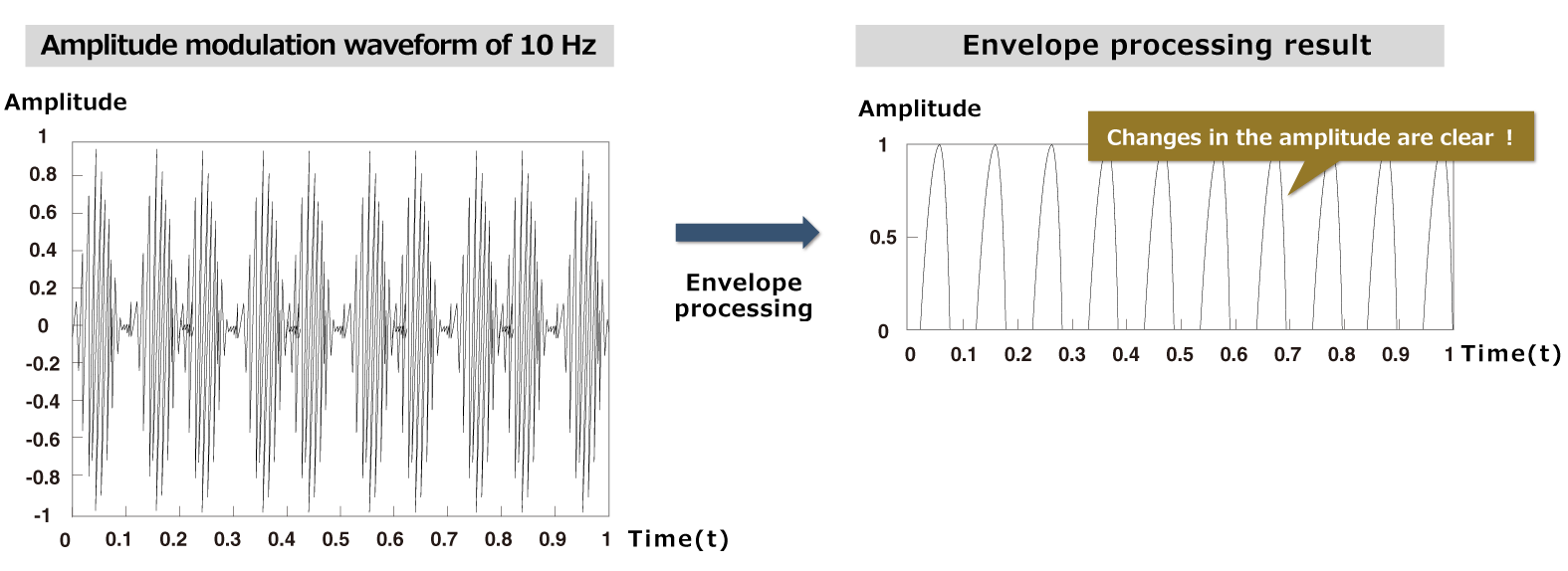

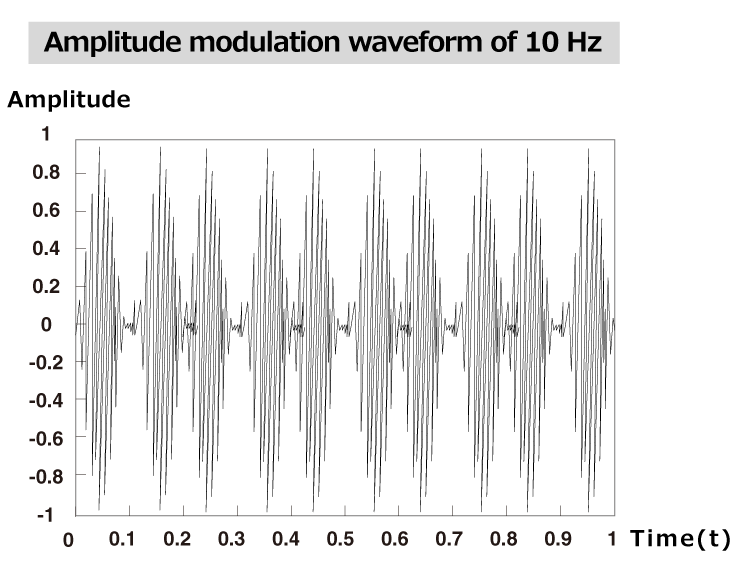

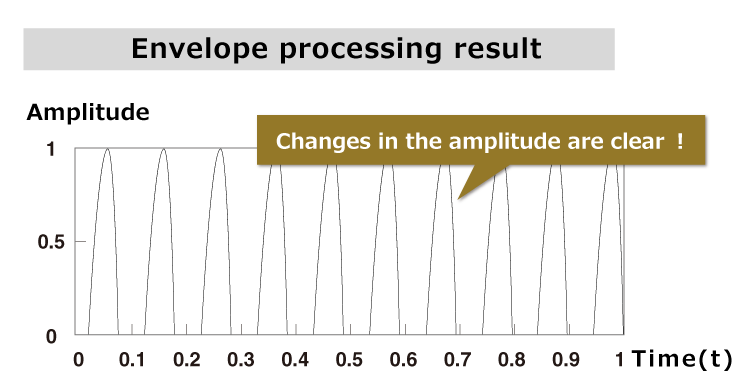

Envelope

Envelope processing is a process to extract the outline of absolute amplitude values. It is used to examine the periodicity of impact vibration, such as the vibration caused by damage to the bearing.

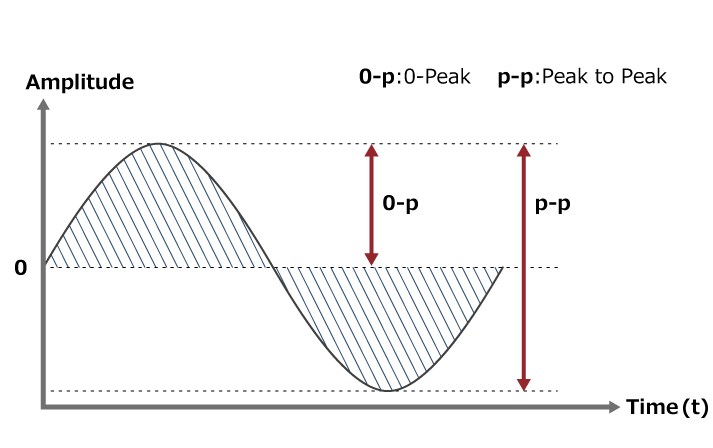

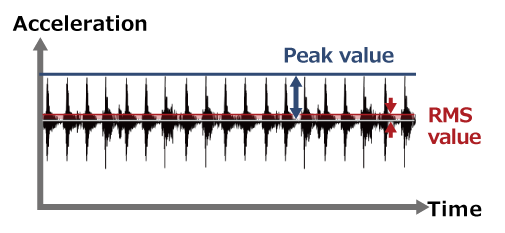

Peak value

The maximum value of amplitude in a waveform for a certain period. The peak value is represented as Peak to Peak and 0-Peak.

It is used for evaluating the impact vibration and vibration waveform with small variations.

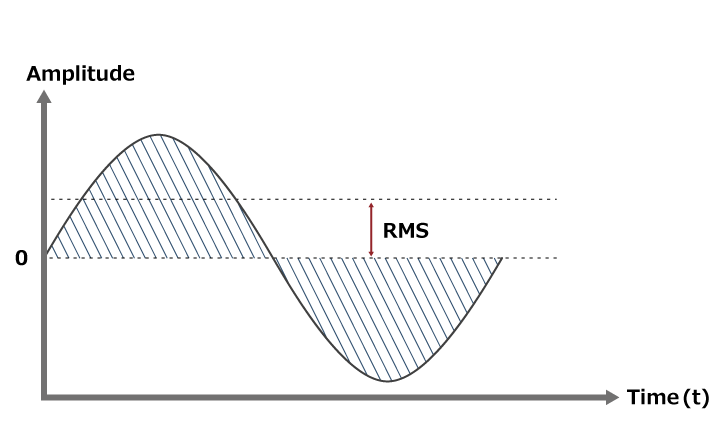

RMS(effective value)

The square root of mean square for each instantaneous value within a certain period in the time-domain waveform. It indicates the average amplitude of the time-domain waveform.

It is used for evaluating the vibration waveform with few impact vibrations.

The velocity RMS is used for total judgment of the equipment condition. The acceleration RMS is used for calculation of crest factor.

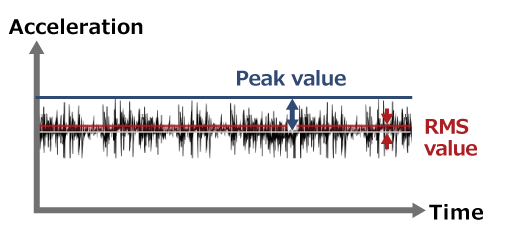

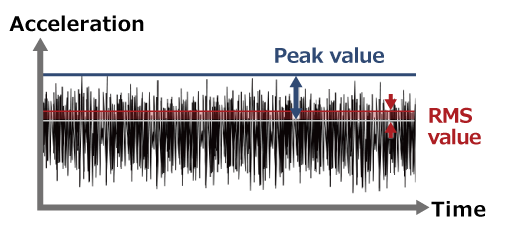

Crest factor(CF)

A ratio of RMS value and peak value of time-domain waveform. (Crest factor = peak value/RMS value)

While the peak value and RMS value vary according to the rotation speed, the crest factor is less likely to vary but increases due to impact vibration.

Therefore, the crest factor is used for detecting impact vibration such as damage on a bearing.

Vibration state |

Time-domain waveform |

Crest factor value |

|---|---|---|

Normal |

|

(CF << 5) |

Motor load increased due to |

|

(CF ≈ 6) |

Impact vibration due to damage |

|

(CF >> 5) |

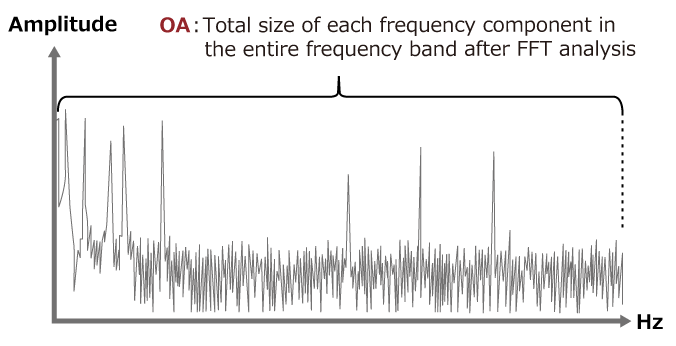

Overall (OA)

The total size of each frequency component in the entire frequency band after FFT analysis.

Theoretically, OA equals to RMS value of the waveform before FFT analysis. It is used to monitor the amplitude in the entire frequency band after FFT analysis.

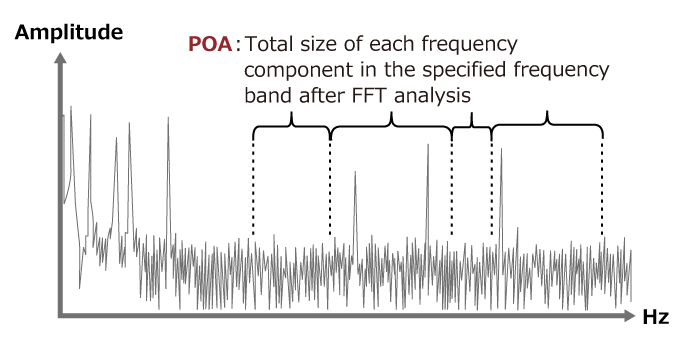

Partial overall (POA)

The total size of each frequency component in the specified frequency band after FFT analysis. It is used to monitor the amplitude in the specified frequency band after FFT analysis.

Terminology for the MT method

Item (Input field for MT method)

The characteristic value extracted from the source information (such as vibration) used to generate a unit space or calculate the Mahalanobis distance.

"iQ Monozukuri Rotary Machine Vibration Diagnosis" uses the POA value of vibration and other items.

If any unnecessary item is included in the unit space, it may affect the accuracy of error judgment.

Unit space

Reference data (normal data) group for calculating the Mahalanobis distance.

Sample

It refers to a set of data for each item measured under normal conditions, which is required to generate the unit space of the MT method.

It is also called sample data.

Mahalanobis distance

An index that shows the amount of deviation from the reference data group.