Code Reader Features

Read various codes

The code reader is equipped with 2-D code reading algorithm PowerGrid and 1-D code image processing algorithm HotBarsⅡ. PowerGrid technology provides reliable reading of challenging 2-D codes which exhibit damage to or complete elimination of the finder pattern, clocking pattern, and quiet zone. In addition, HotBarsⅡ delivers reading of reflected, damaged or poorly printed 1-D codes as small as 0.8 pixels per module.

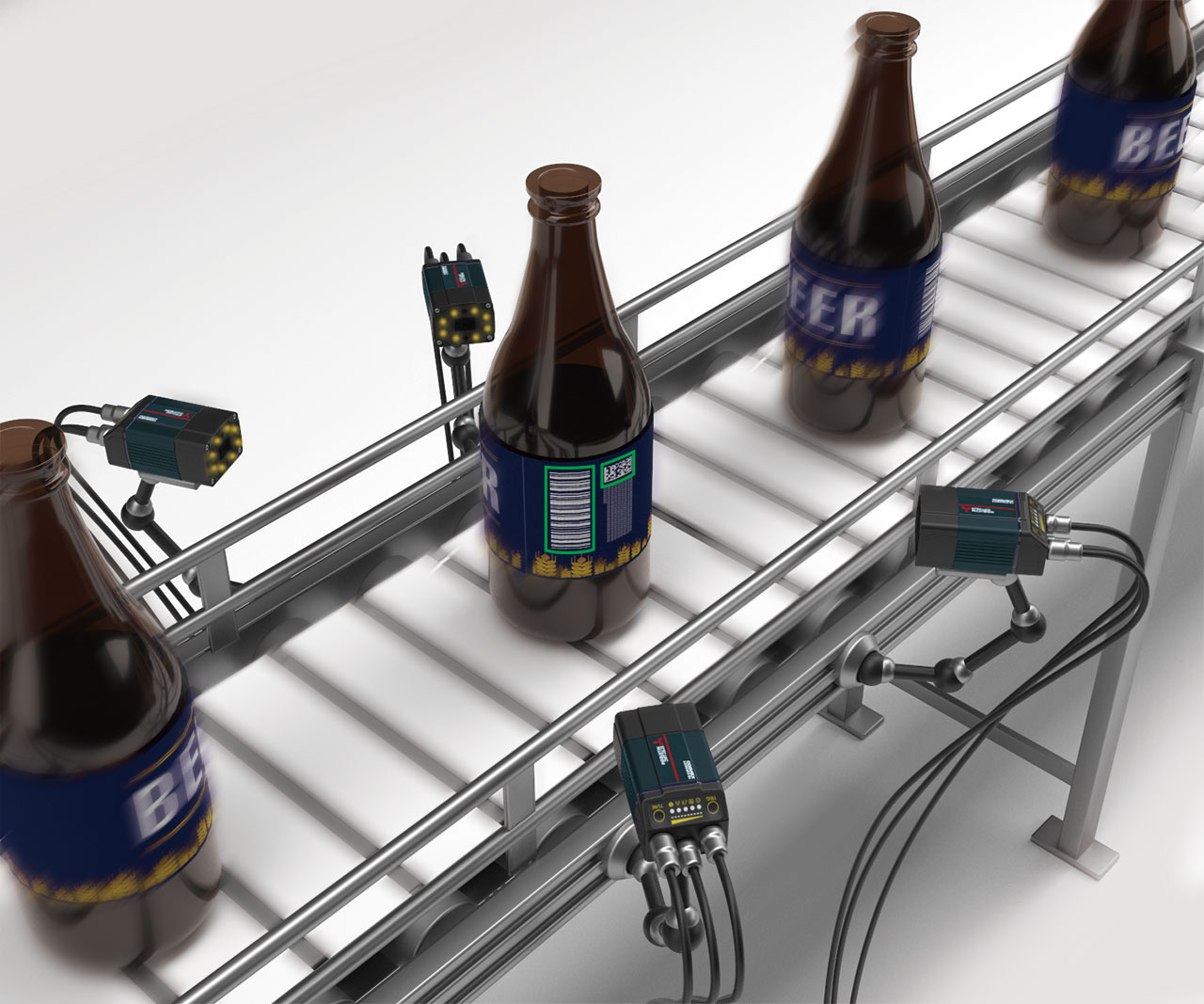

Reliably read codes with difficult conditions

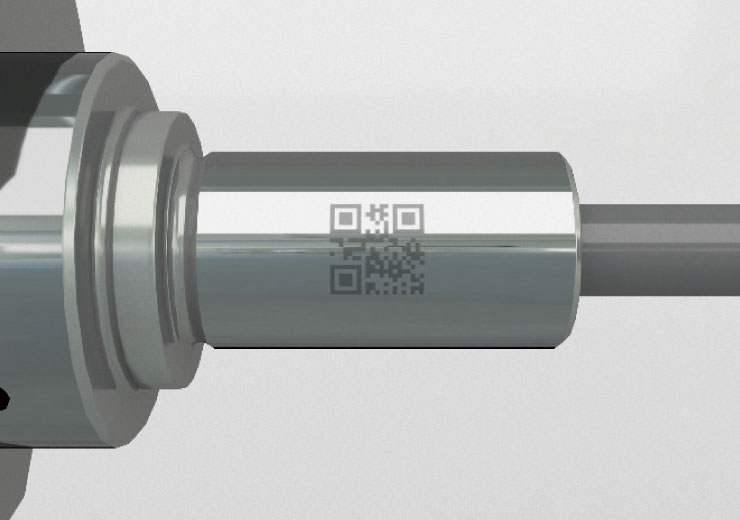

A combination of high-powered light, polarized front cover and liquid lens provides a good reading condition. Codes at long working distances, on high-speed application, on round, shiny, highly reflective, or specular surfaces can be reliably read.

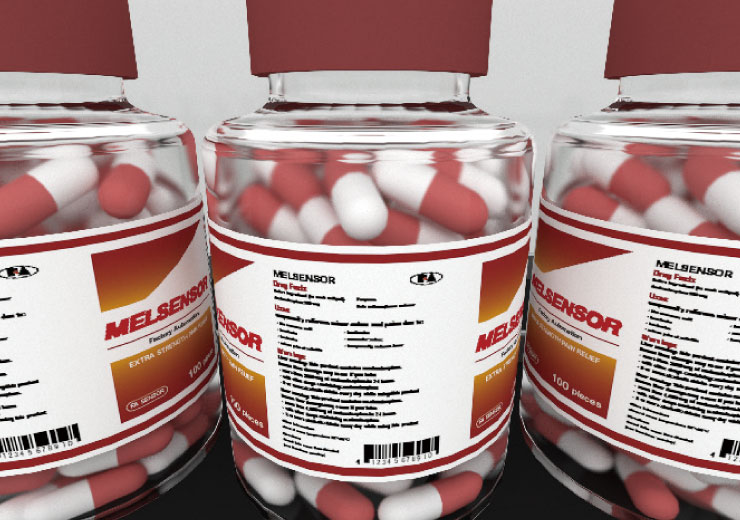

Codes on the round surface

Codes on the shiny and highly reflective surface

Codes moving at high speed

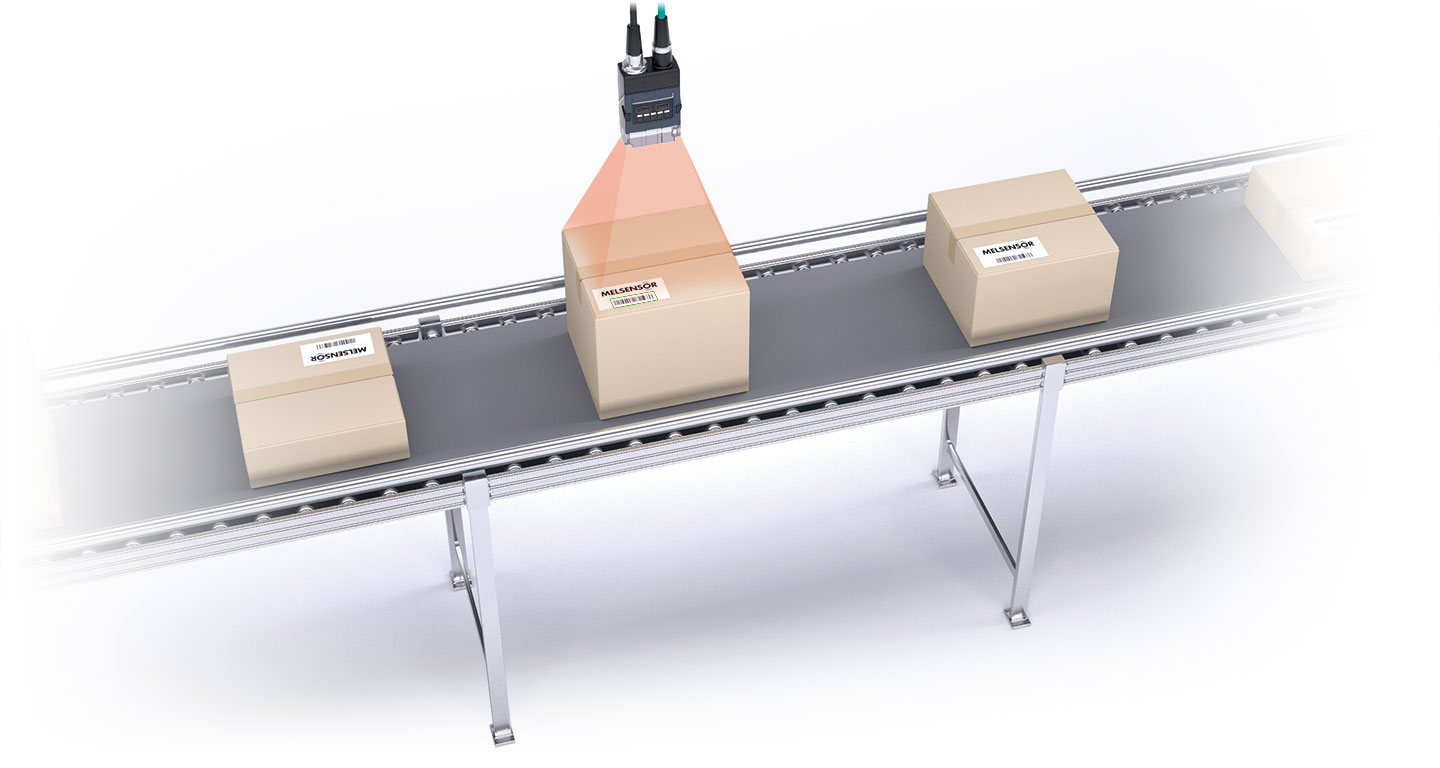

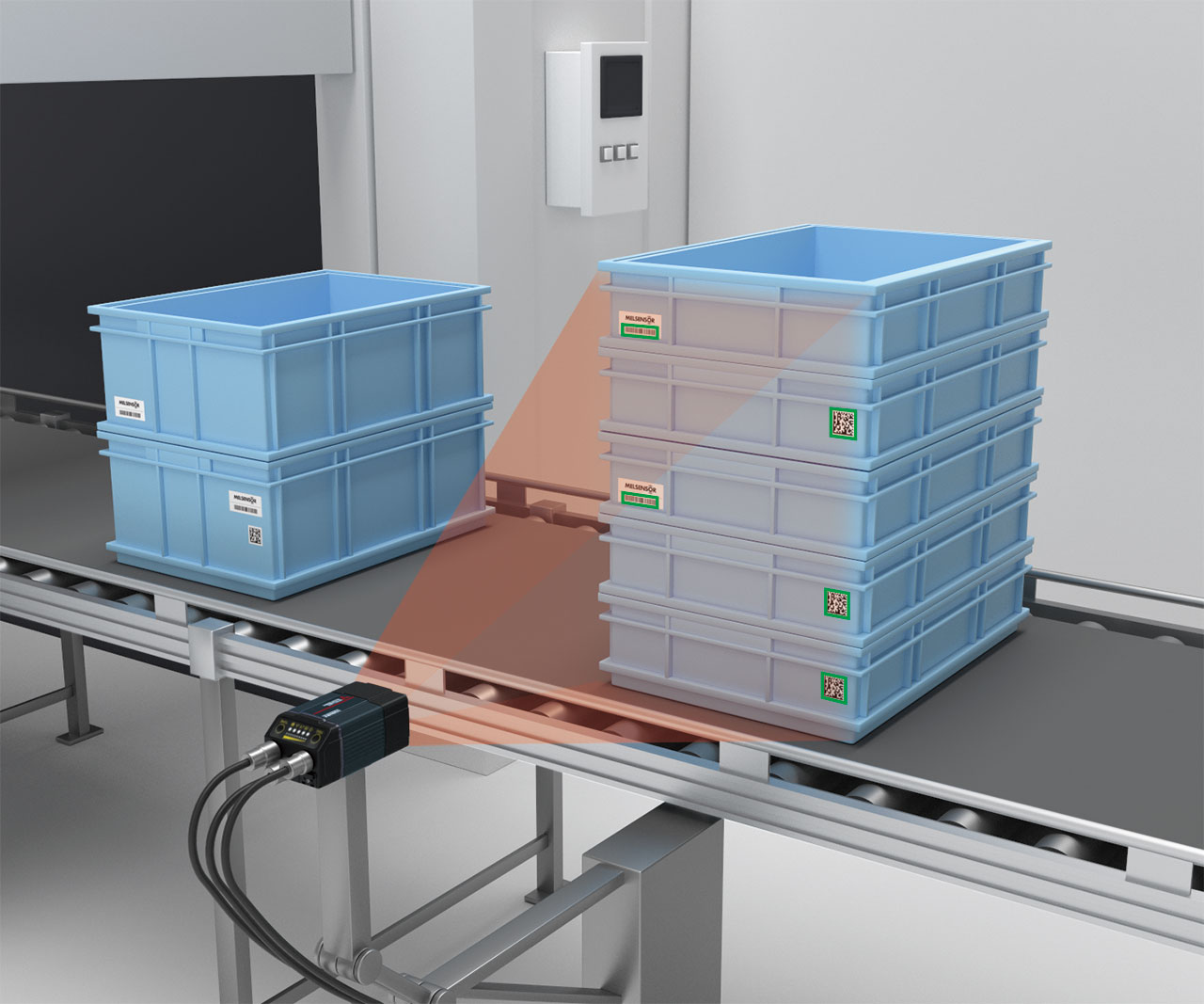

Codes at different places and heights

With a wide field-of-view and unique algorithm, the code reader can read codes in different places and depths.

This is ideal for codes at different reading distances such as cartons with varying heights on the moving conveyor.

Easy installation reduces setup cost

Embedded autofocus function

Pressing a button on the code reader quickly sets the optimum focus automatically. Manual focus setting is unnecessary, simplifying the setup.

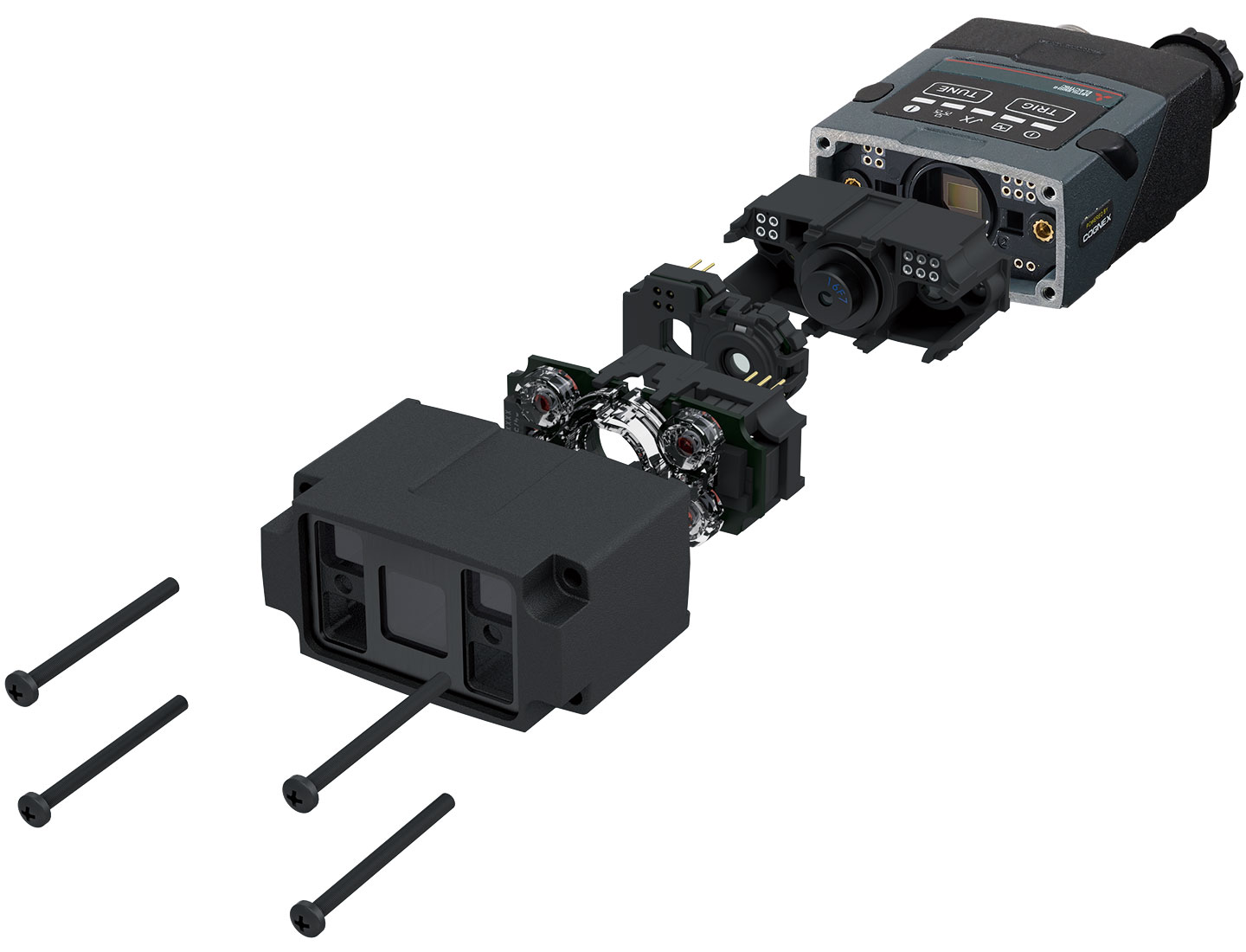

Integrated code reader

- High-power illumination is integrated

Four high-powered red LED illuminations provide an optimum illumination condition. The code reader has integrated lighting and does not require angle adjustment of illumination. Additionally, hardware cost can be reduced by eliminating the need for separate illumination. - Liquid lens

The code reader uses liquid lenses which do not have any moving parts that can wear out or fail, thereby reducing maintenance cost.

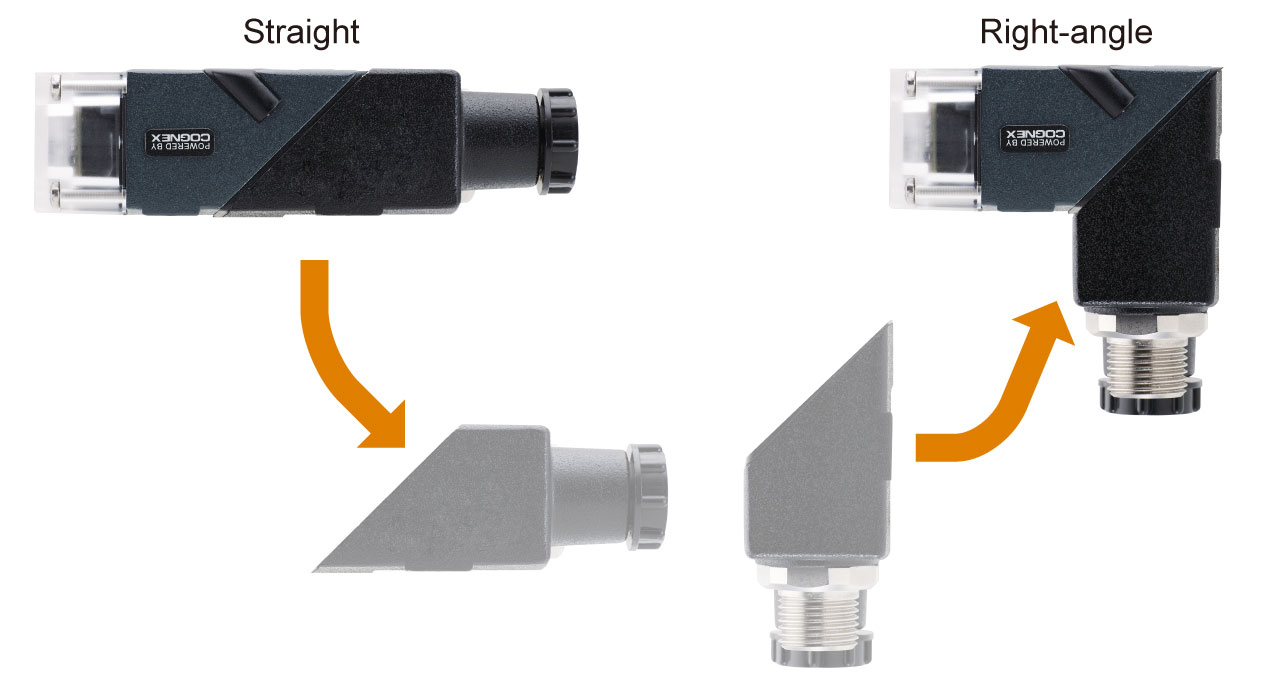

Customizable according to installation conditions

Configuration can be changed according to the installation space

The configuration can be changed between in-line and right-angle. By changing the configuration according to the installation space, the code reader can be installed by the wall or in tight spaces where wiring orientation is constrained.

Compact palm size

The CF26-SR is a compact size with 44.0 × 22.5 × 79.3 (mm) and can be used in a tight installation space.

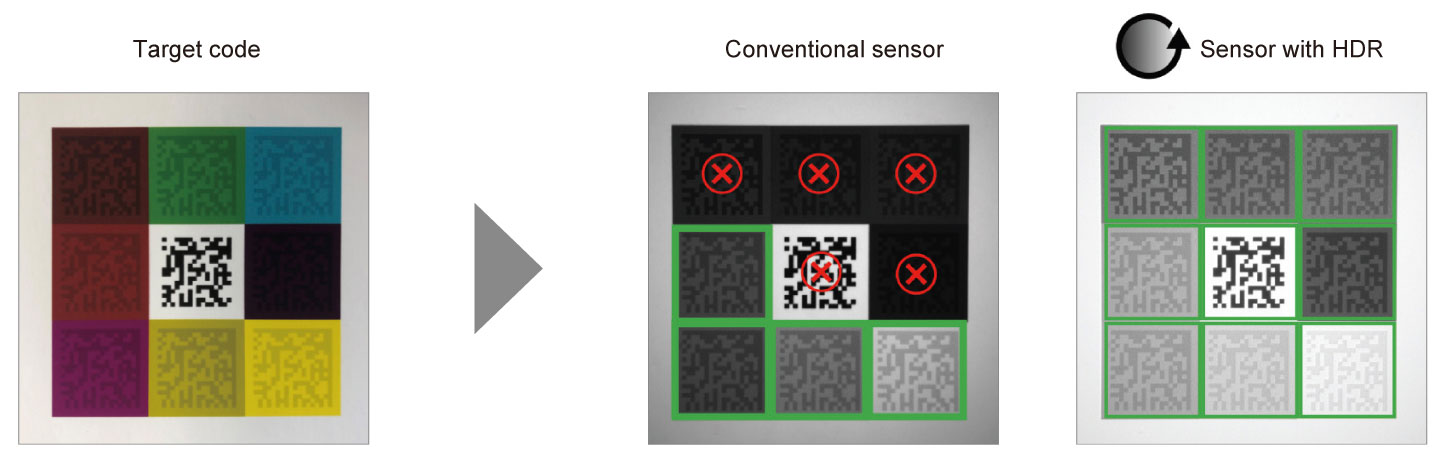

High Dynamic Range (HDR) image processing

HDR imaging uses the latest CMOS image sensor technology to globally enhance image quality, resulting in greater depth-of-field, faster line speeds, and improved code handling.

With HDR technology enhancing contrast, the CF37 can read difficult codes which are unreadable with a conventional sensor resulting in low contrast images.

High resolution

The CF37 achieves higher resolution and a wider field-of-view as compared with the CF26. With its greater field-of-view coverage, one sensor can read multiple codes simultaneously as well as codes on the objects with different heights.

High-speed decoding

Equipped with a multi-core processor and high-speed engine, high-speed code reading performance has been further improved. This is useful for applications containing high-speed conveyors where product codes must be read in quick concession.