Energy Measuring UnitsEcoMonitorLight

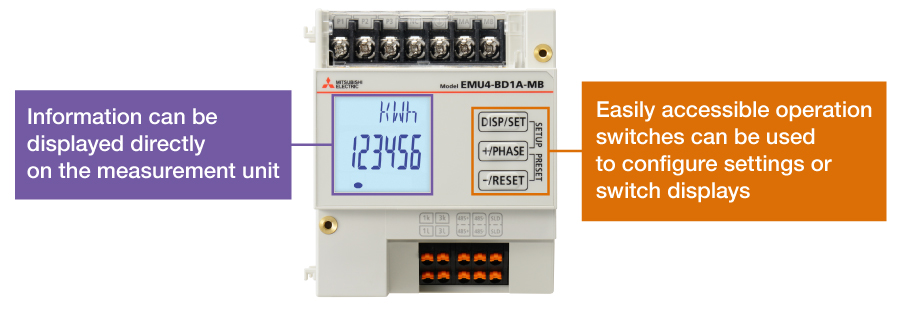

Easy Measurement and Installation

The built-in LCD screen makes it possible to view settings, measurements, and other information necessary for energy measurement with no additional equipment required.

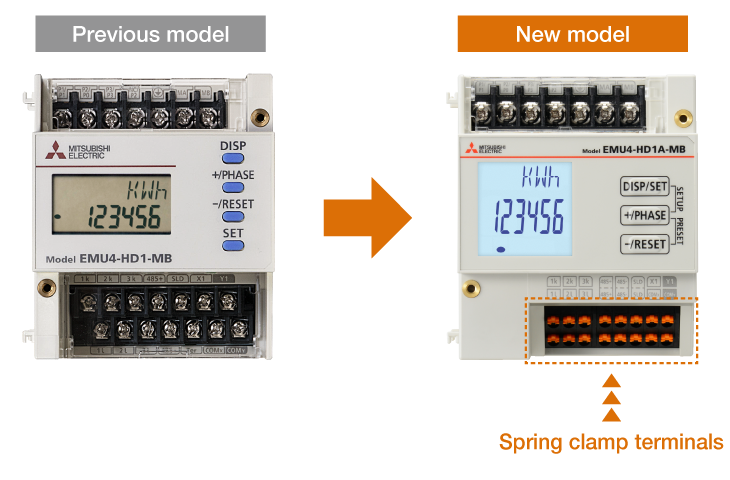

Spring Clamp Terminal Blocks

The spring clamp terminal blocks help improve efficiency, including by eliminating the need to tighten screws.

Automatic Identification of Phase Type and Rated Voltage

Automatic determination of the phase type and rated voltage is possible by analyzing the measured voltage (magnitude and phase), allowing for estimation of setting values.

*1:Accurate estimates may not be possible if the current phase is significantly out of phase or if there is excessive noise, so users must confirm that the estimated setting values and circuit conditions are appropriate for the application.

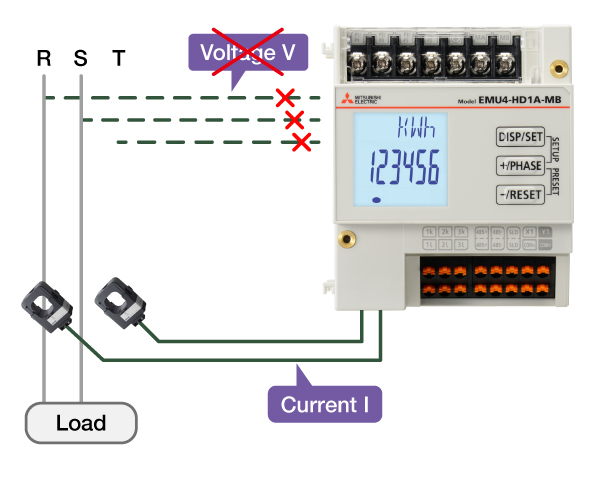

Easy Measurement with No Voltage Input Required

Measure even where voltage wiring can’t be installed

This function measures power using only the current input and assuming a fixed voltage (e.g., 220 V).

*1:Auxiliary power input required. (Auxiliary power rating: 100 to 240 V)

Production Equipment Status Monitoring

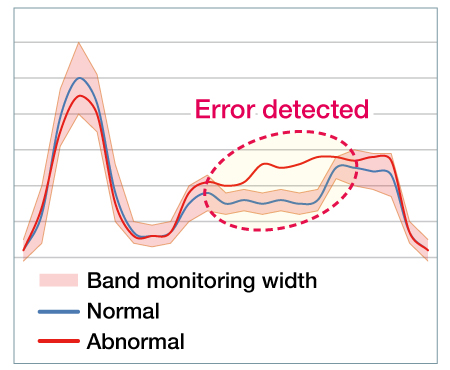

Band monitoring function

*1:Available on high-performance models only. Cannot be used simultaneously with the alarm frequency monitoring function.

Monitoring load currents associated with blade deterioration to detect pattern deviations

This function monitors the degree of deviation from the normal load current waveform to monitor equipment with repeated operations. The monitored values of the waveform band are used to determine normal and abnormal load current waveforms.

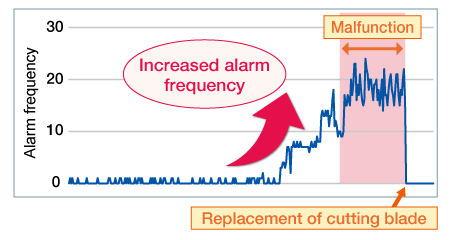

Alarm frequency monitoring function

Monitoring load currents associated with blade deterioration to detect alarm frequency

In addition to conventional upper and lower limit alarm functions, the alarm frequency monitoring function makes it possible to track the number of alarms (upper and lower limit alarms) that occur. Analyzing per-hour alarm occurrence trends makes it possible to monitor the status of equipment.