Energy Measuring UnitsEcoMonitorPlus

Economical Extendibility

Building block method for economical extendibility

Basic configuration

Number of measurement points

Structure

Reduced wiring

Preventative Equipment Maintenance

Predictive monitoring of equipment failure as a preventative maintenance tool

Applicable products

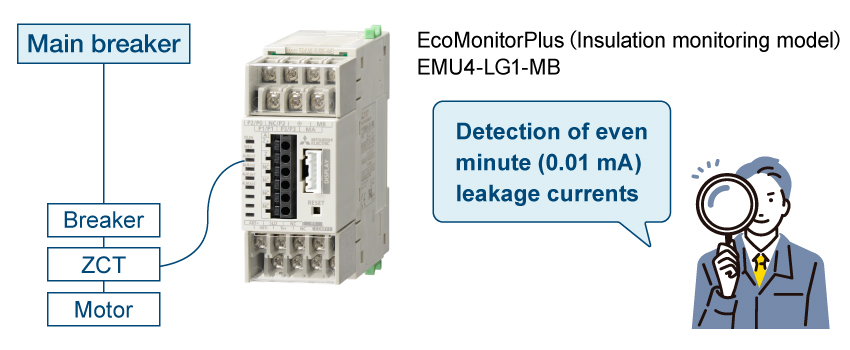

Insulation monitoring model

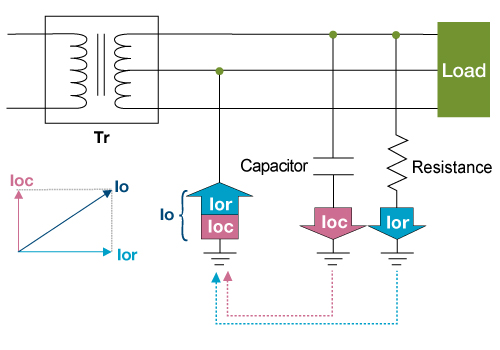

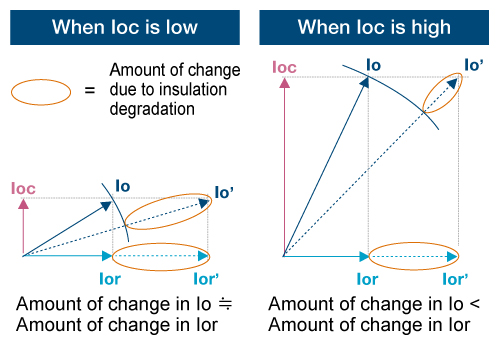

Leakage current measurement method (Ior method)

Even for inverter circuits with a large capacitor-component leak current (Ioc), which is difficult to monitor using the conventional Io method, removing the Ioc amount makes it possible to accurately monitor the leakage current due to insulation degradation using the resistive leakage current (Ior).

Ior ・・・ Leakage current (resistive leakage current) due to insulation degradation

Ioc ・・・ Leakage current even with good insulation (leakage current from electrostatic capacity)

Io ・・・・ Composite leakage current of Ior and Ioc (vector composition)

Ioc is higher in equipment with long wiring distances or with inverter devices or various filters installed, so detecting insulation degradation (due to small changes in Io) becomes difficult and Ior measurement is more effective.

*1:Accurate measurement is not possible on the secondary side of inverters and servo amplifiers.

*2:Measurement is possible with single-phase 2-wire, single-phase 3-wire, and three-phase 3-wire delta circuits. For three-phase 3-wire star circuits, three-phase 4-wire circuits, and special grounding circuits such as high-resistance grounding circuits and capacitor-grounding circuits, only Io measurement is possible.

High-sensitivity mode (Measurement resolution: 0.01 mA)

High-sensitivity mode ensures that even slight equipment fluctuations and motor or other device load degradation conditions in production equipment are reliably identified.

Detailed trend monitoring

Applicable products

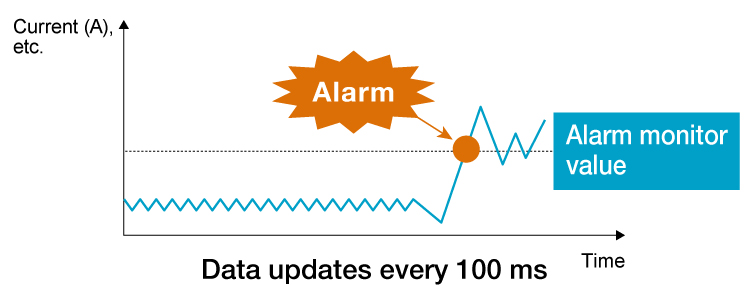

Energy measurement model

Real-time monitoring of failure conditions with data updates every 100 ms

Ensure reliable detection of increased load current and power fluctuations caused by equipment degradation or pump/motor malfunctions.

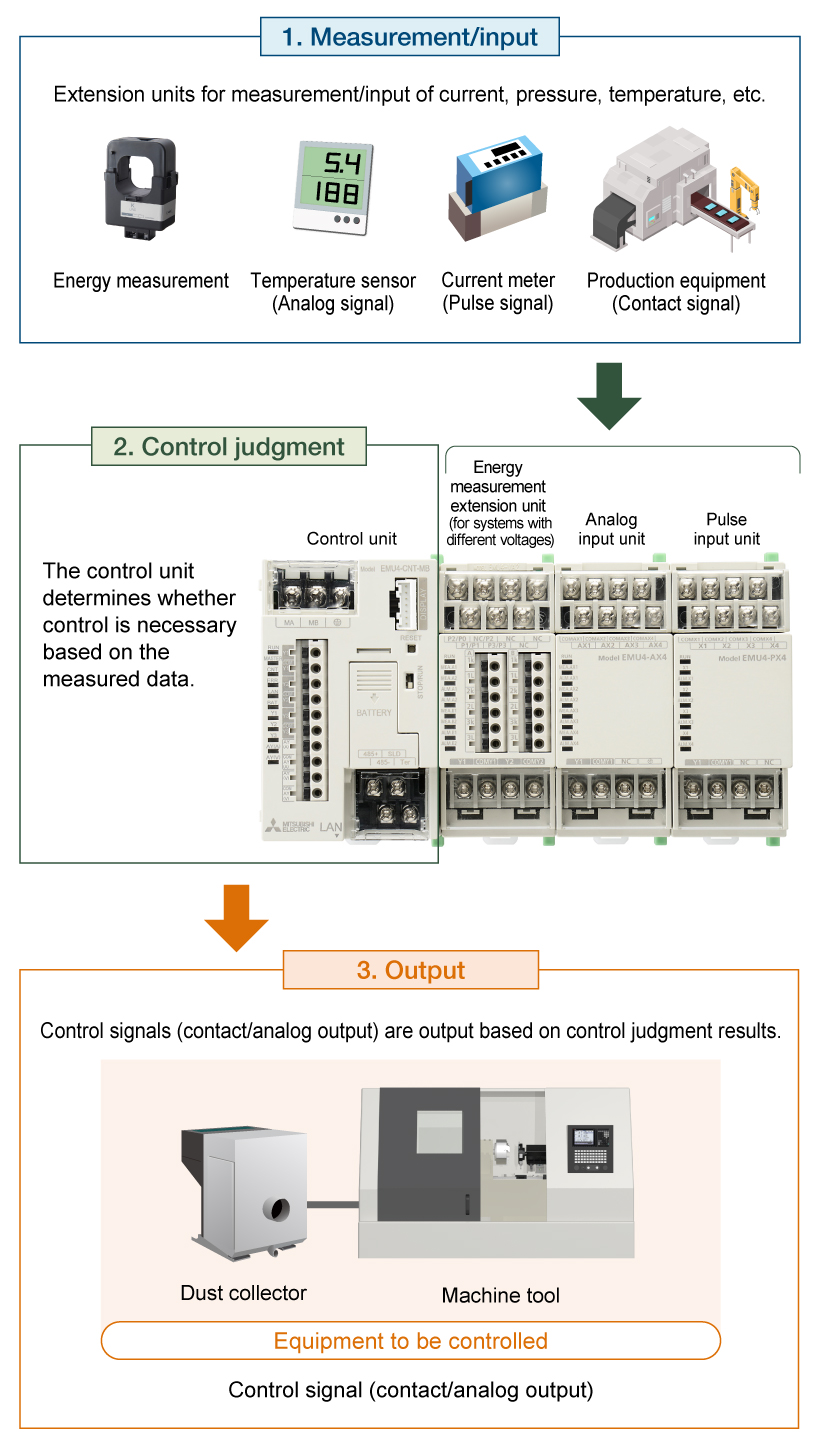

Energy Saving Control

Energy Saving Control of ancillary utility and production equipment

Improve equipment energy savings using units with control functionality

Using units equipped with a function to turn equipment on or off according to measured values makes it possible to improve the energy savings of ancillary utility and production equipment in factories. Control units can be easily configured from a PC using the dedicated engineering tool.

Control function overview