Human-Machine Interfaces(HMIs)-GOT GOT SIMPLE Series

GOT SIMPLE Series remote solutions

Safety precautions

When iQ Monozukuri products or the VNC Server function are used to perform remote control of control equipment, the field operator may not notice the remote control, possibly leading to an accident. In addition, a communication delay or interruption may occur depending on the network environment, and remote control of control equipment cannot be performed normally in some cases. Before using these functions to perform remote control, fully grasp the circumstances of the field site and ensure safety.

Monitor from remote locations

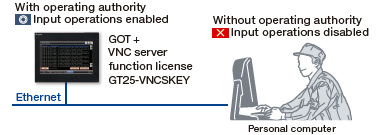

VNC server function*1 *2

Monitor production remotely

Remotely view the GOT screen from information devices such as a PC and tablet. No dedicated screens are required.

- *1A separate license (GT25-VNCSKEY-□) is required.

- *2One client can connect to one GOT at the same time.

On a PC in your office

Same functions as GOT

Utility functions including the backup/restoration function and the device monitor are also supported on computers and tablets.

On a tablet from a remote location

Safe operation avoiding simultaneous operations

Authorization function prevents accidents that might be caused by simultaneous operations by multiple operators.

Application examples

Check the alarm without visiting the shop floor

From a remote office, you can easily monitor the alarms. Check the alarm and corrective actions in detail, and you can solve the problem quickly and reduce downtime.

Easily startup large equipment

When starting up and adjusting large-scale equipment, you may have to work away from the GOT. You can now check the GOT screen using a tablet from a remote location so that all the work can be done by a single operator efficiently.

Specification details and restrictions

For the supported connection types and necessary option devices, please refer to the

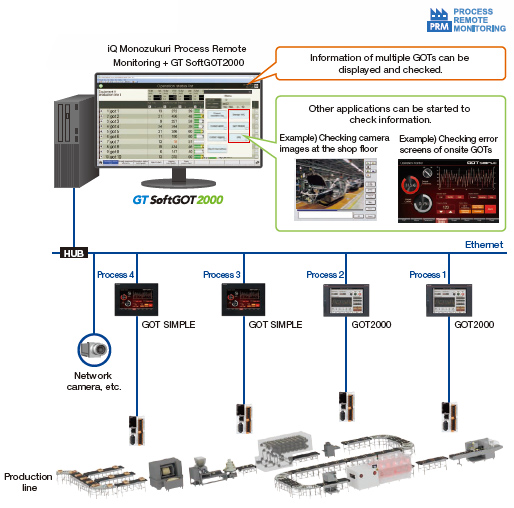

Improve manufacturing process and productivity of the whole production

iQ Monozukuri Process Remote Monitoring*1

Easily monitor multiple devices from a remote office

IoT technologies can be easily introduced to the shop floor, and the information of multiple equipment can be collected, visualized, and managed collectively. Manufacturing process and productivity of the whole production can be improved by analyzing the data displayed on GT SoftGOT2000*2. The operation status of the shop floor and the information such as operation logs and alarms can be collected from each device via an onsite GOT.

- *1iQ Monozukuri Process Remote Monitoring application package is required separately. For more details, please refer to the iQ Monozukuri Process Remote Monitoring catalog.

- *2A license key (GT27-SGTKEY-U) is required separately.

Easily implement production visualization system

The template project for GT SoftGOT2000 makes it easy to startup systems.

Share the information of the shop floor with pictures and text

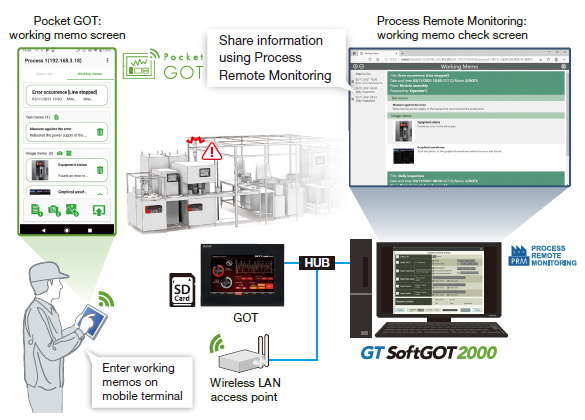

Pocket GOT mobile app: Working memo function

(Interaction function with the iQ Monozukuri Process Remote Monitoring)

By installing the Pocket GOT mobile app on

a mobile terminal, working memos can be created to share the information such as the daily check results of on-site equipment and the status report at the error occurrence.

The working memos can save text, pictures taken, and images saved in the mobile terminal.

The created working memos can be sent and saved to the connected GOT. iQ Monozukuri Process Remote Monitoring collects the working memos saved in the GOT, allowing you to check them collectively on a PC and to create reports for each date, time, and place.

- *Pocket GOT can be used on iPhone, iPad [NEW] , or Android™ devices.