Human-Machine Interfaces(HMIs)-GOT GOT SIMPLE Series

GOT Drive Control (Inverter) Interactive Solutions

Challenges that cannot be resolved just with the inverter can now be resolved with GOT SIMPLE and inverter interactive functions.

The GOT Drive enhanced functionality is designed to eliminate need for additional hardware, software and suits customer's applications to realize central monitoring, speed up system startup, improve predictive maintenance and troubleshooting.

System configurations

See Supported models and versions for details.

With GOT, the inverter's parameters can be adjusted with the control panel closed

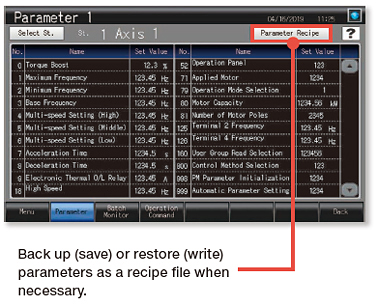

Parameter settings (simple mode)

Use the GOT on the front of the control panel to adjust the inverter's simple mode parameters. The parameter names can be confirmed on a list, so the required parameters can be easily found and set.

Parameter Setting screen*1

- *1Parameters and devices to be monitored can be set and displayed on a screen. These are screen creation examples.

With GOT, the inverter's parameters can be monitored in a batch with the control panel closed

Batch monitor

The inverter's current values such as the output frequency, output current, and output voltage can be monitored with the GOT without preparing the PC or directly confirming the inverter.

Batch Monitor screen*1

- *1Parameters and devices to be monitored can be set and displayed on a screen. These are screen creation examples.

With GOT, the replacement timing of the inverter's components can be displayed and predictive maintenance can be performed

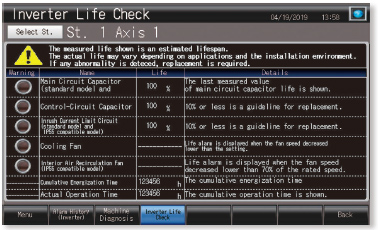

Inverter life diagnosis

GOT can be used to monitor the operation status of the inverter's components (main circuit capacitor, control circuit capacitor, etc.) and confirm the replacement timing. Perform predictive maintenance by replacing parts before the inverter fails.

Inverter Life Diagnosis screen*1

- *1Parameters and devices to be monitored can be set and displayed on a screen. These are screen creation examples.