MELSERVO-J4 Series Rotary Servo Motor

Product lines

- •Ultra-large capacity servo motors with functional safety

HG-JR_K24W0C 400 V class: 110 kW, 150 kW, 180 kW, 200 kW, 220 kW - •Drive units for the ultra-large capacity servo motors

MR-J4-DU_KB4-RJ100 400 V class: 45 kW and 55 kW

Features

- •Servo motors with functional safety

Safety level is Category 4 PL e, SIL 3 with a combination with MR-D30 functional safety unit.

- •Ultra-large capacity servo systems can be configured with multiple drive units driving the servo motor parallelly.

Ideal for increasing machine output and replacing conventional hydraulic systems

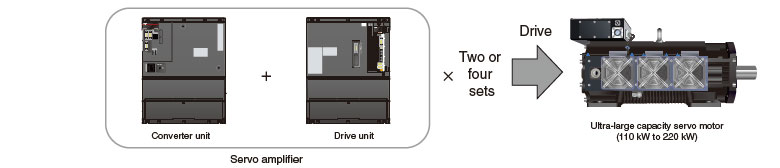

The ultra-large capacity servo motor is driven by parallelly connected two or four sets of MR-CV55K4 power regeneration converter units and MR-J4-DU_KB4-RJ100 drive units.

Using power regeneration system, the converter units effectively use regenerative power and support a power saving system.

•Example of parallel drive system configuration

Parallel Drive System

The converter unit and drive unit are used as a combination. Two or four sets of these parallelly drive the ultra-large capacity servo motor of 110 kW to 220 kW.

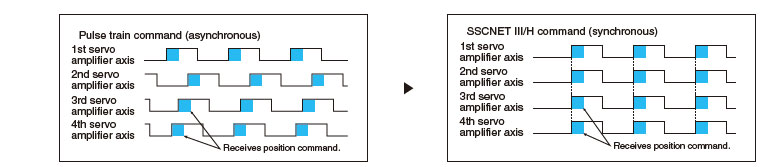

Highly accurate synchronous communication of SSCNET III/H enables a large-capacity parallel drive system.

•Timing of servo amplifier processing

![]()

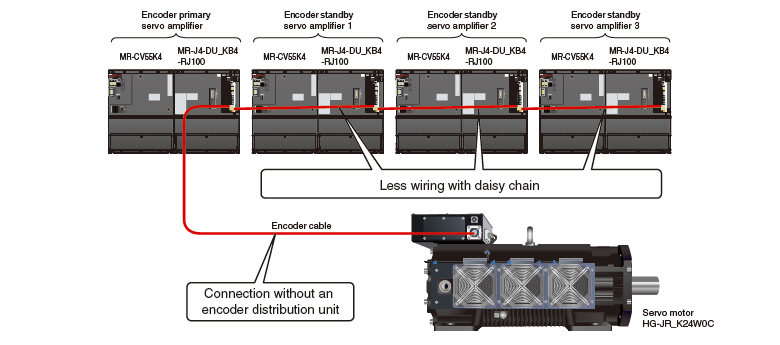

Simple Encoder Connection

The drive units and the servo motor offer easy, cost-effective connection with less cables. The drive units are connected with daisy chain encoder cables, and encoder information is sent from the encoder primary servo amplifier to all of the encoder standby servo amplifiers without an encoder distribution unit.

In addition, thermistor signal wires are included in the encoder cable, and thus additional wiring for thermistor signal is no more necessary. The simple connection helps reduce complication and errors.

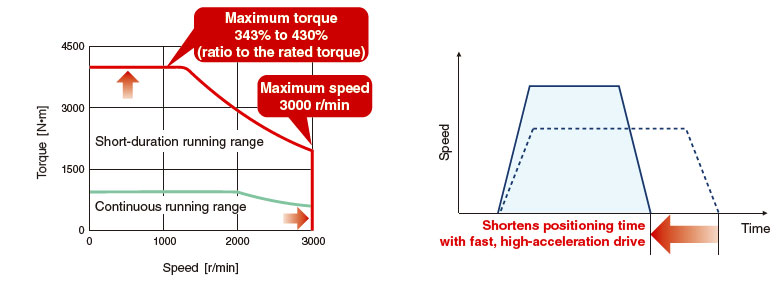

High-Speed, High-Torque Servo Motors

The rotor structure of the servo motor is optimized to provide high-speed, high-torque operation. The fast, high-acceleration drive shortens positioning time and boosts your productivity.

- * As an example of HG-JR220K24W0C

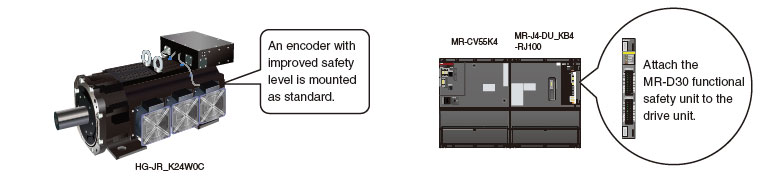

Increased Safety Level

The HG-JR_K24W0C servo motors are equipped with an encoder with improved safety level.

Use of the drive unit, MR-D30 functional safety unit, and the servo motor with functional safety provide the safety level up to Category 4 PL e, SIL 3 and the following functions: Safe torque off, Safe stop 1, Safe stop 2, Safe operating stop, Safely-limited speed, Safe brake control, and Safe speed monitor.

- * Refer to "MR-J4-DU_B4-RJ100 Drive Unit Instruction Manual" for details on the use of MR-D30 functional safety unit combined with the drive unit.

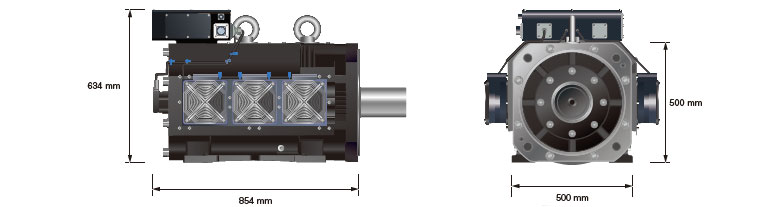

Industry's Shortest Class

Cooling fans are mounted on the sides of the servo motor, making the motor length shorter than ever. The industry's shortest class has been achieved.

- * As an example of HG-JR220K24W0C

Application Examples

A wide capacity range of the ultra-large servo motors supports an increase of machine output and replacement of your conventional hydraulic system with an electric system.

Press Machines

Molding machines

Loaders, unloaders, and feeders

Material handling systems

Vibration testing machines

Spin coaters