MELSERVO-J4 Series Servo Amplifier

Multi-Axis Servo Amplifier in Harmony with Eco-Friendly Society

2-axis/3-axis Types for Energy-Saving and Miniaturized Machine

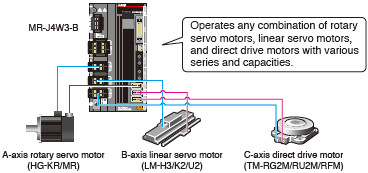

2-axis and 3-axis servo amplifiers are available for operating two and three servo motors, respectively. These servo amplifiers enable energy-saving, compact machine. Different types of servo motors including rotary servo motors, linear servo motors, and direct drive motors are freely combined as long as the servo motors are compatible with the servo amplifier*.

- * For the combination, refer to "Combinations of Multi-Axis Servo Amplifier and Servo Motors".

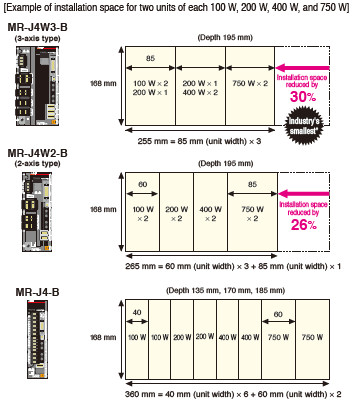

Space-Saving with Industry's Smallest* 3-axis Type

2-axis servo amplifier MR-J4W2-B requires 26% less installation space than two units of MR-J4-B. 3-axis servo amplifier MR-J4W3-B requires 30% less installation space than three units of MR-J4-B.

* Based on Mitsubishi Electric research as of February, 2019

Reduced Wiring by Approx. 50% with 3-axis Type

The three axes of 3-axis servo amplifier MR-J4W3-B use the same connections for main and control circuit power, peripheral equipment, control signal wire, etc. Thus, the number of wirings and devices is greatly reduced.

Optimal Energy-conservative System for Your System

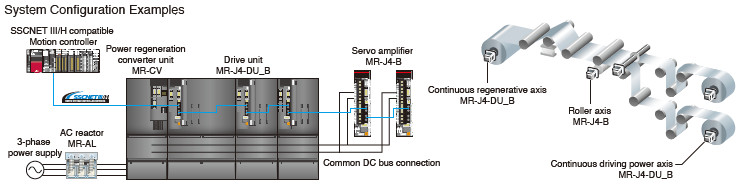

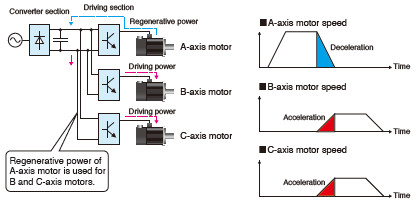

Energy-conservation with Common DC Bus Connection

When multiple servo amplifiers and drive units are connected to the MR-CV power regeneration converter unit by a common DC bus connection, the regenerative power of one axis is used for driving other axes, contributing to energy-conservation.

The multi-axis servo amplifier has the same effect.

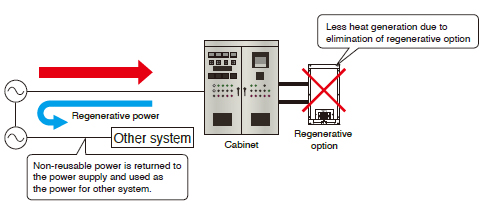

Further Energy-conservation with Power Regeneration System

The MR-CV power regeneration converter unit has a power regeneration system which returns the regenerative power back to the power supply, enabling the regenerative power to be used for other systems for further energy-conservation.

In addition, when the MR-CV power regeneration converter unit is used, a regenerative option is not required, and thus, the total heat generation in a system will be decreased.

Advanced Function and Performance for More Energy-conservation

Reduced energy loss of servo amplifier and servo motor

[Servo amplifier] Efficiency is increased by the use of a new power module.

[Servo motor] Motor efficiency is increased by optimized design of magnetic circuit.

Energy-conservation due to the improved machine performance

The servo amplifiers and the servo motors with the industry-leading level of high performance reduce machine cycle time and operation time, resulting less energy consumption.

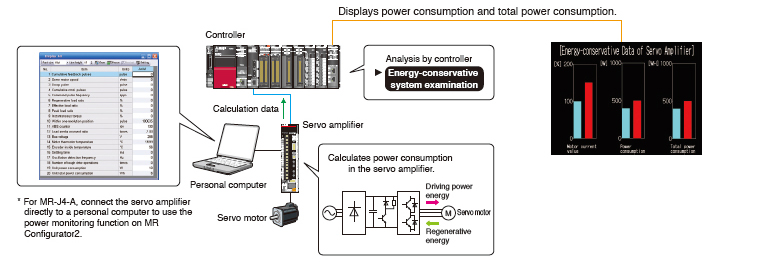

Power Monitoring Function

Driving/regenerative power is calculated from the data such as speed and current in the servo amplifier, and MR Configurator2 monitors the operation data including power consumption. In a system of CC-Link IE Field Network or SSCNET III/H, the data are transmitted to a controller, and the power consumption is analyzed and displayed.

Energy-conservation Achieved by LM-H3 Linear Servo Motor Series

Reduced motor driving power

LM-H3 has achieved a reduction of 25%* in motor driving current due to a new magnetic design with optimized magnet form, contributing to power conservation for machines. The motor coil is lighter by approximately 12%* as compared to the prior model, which also contributes to saving energy for driving the moving part.

- * For 720 N rated linear servo motor

Space saving

For LM-H3, widths of the motor coil and the magnet are reduced by 10% from the prior model. Increased thrust to current ratio results in using the servo amplifier in smaller capacity, contributing to more compact machine (the reduction of materials).

Environment

Expanded Environmental Conditions

Capable of operating at an altitude of up to 2000 m.

Compatible with power supply voltage of 240 V AC for global use.

Complies with Restriction of the Use of certain Hazardous Substances in Electrical and Electronic Equipment (RoHS) - Directive

Servo amplifiers with special coating-specification are now available. This servo amplifier has an improved corrosion resistance in environments with corrosive gas concentrations, conforming to IEC 60721-3-3:1994 Class 3C2. For details, contact your local office.