Inverters-FREQROL Product Features Equipment maintenance

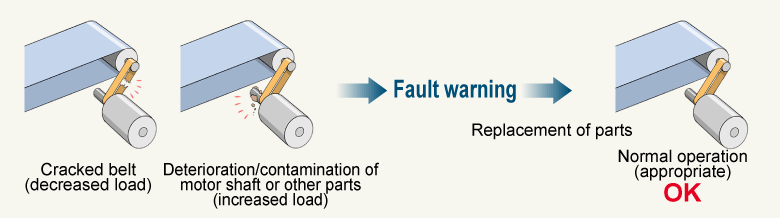

Conveyor belt fault detection

Current detection function

- Faults caused by deteriorated motor shaft (increased load) or cracks in the belt (decreased load) can be detected through the motor output current.

- If the output current exceeds the predetermined value, a signal is output to inform the user of the faulty device.

- By using parameter settings, the inverter can be stopped when a signal is output at the point a fault occurs.

▪ Fault detection and warning output

| Pr. | Name | Description |

|---|---|---|

| 150 | Output current detection level | Set the reference value of normal load characteristics. |

| 152 | Zero current detection level | Set the maximum frequency of the load characteristics fault detection range. |

| 190 to 196 | Output terminal function selection*1 |

When "12" is set, the Y12 signal is output if the output current exceeds the setting value of Pr.150. |

| When "13" is set, the Y12 signal is output if the output current falls below the setting value of Pr.152. |

*1Set Pr.167 accordingly to stop the inverter when a signal is output due to a fault.

〈Applicable models〉

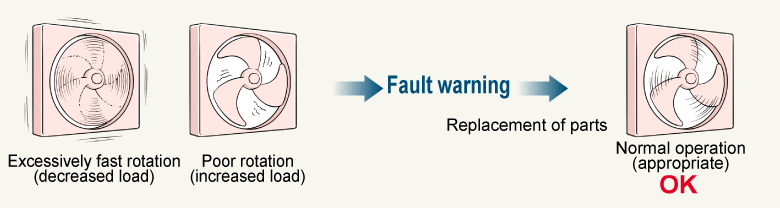

Fan and pump fault detection

Load characteristics fault detection

- The relationship between the speed and torque under normal operation is recorded. (Automatic data acquisition is possible.)

- During actual operation, motor torque is detected and a warning is output if the load exceeds or falls below the predetermined values.

- It is possible to activate the cleaning function by using fault detection as a trigger.

▪ Fault detection and warning output

| Pr. | Name | Description |

|---|---|---|

| 1481 to 1485 | Load characteristics load reference 1 to 5 | Used to set the reference value of normal load characteristics. |

| 1486 | Load characteristics maximum frequency | Used to set the upper frequency limit of the load characteristics fault detection range. |

| 1487 | Load characteristics minimum frequency | Used to set the lower frequency limit of the load characteristics fault detection range. |

| 1488 | Upper limit warning detection width | Used to set the detection range when the upper limit load fault warning is output. |

| 1489 | Lower limit warning detection width | Used to set the detection range of when the lower limit load fault warning is output. |

| 1490 | Upper limit fault detection width | Used to set the detection range of when output is shut off when the upper limit load fault occurs. |

| 1491 | Lower limit fault detection width | Used to set the detection range of when output is shut off when the lower limit load fault occurs. |

〈Applicable models〉

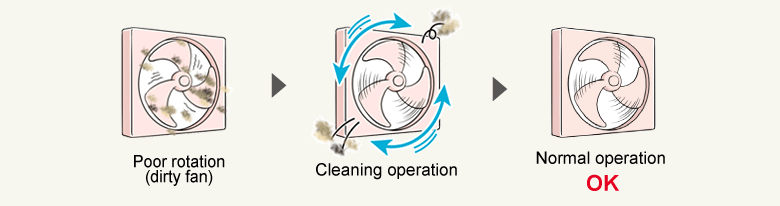

Cleaning function

Dirt and foreign matter on the impellers of fans and pumps can be removed by repeating forward/reverse rotation and stopping of the motor.

This function (working together with the load characteristics fault detection function) can also be started automatically when overload is detected.

This function is intended for uses in which reverse rotation will not cause problems.

〈Applicable models〉

Inverter life diagnosis

Life diagnosis function

The degree of deterioration of the main circuit capacitor, control circuit capacitor, and inrush current limit circuit can be monitored.

With inverter self-diagnostics, a warning when parts have reached their service life is output so that parts or inverters can be replaced before faults

occur.

| Part | How service life is checked | Judgment level | Replacement method |

|---|---|---|---|

| Main circuit capacitor |

With the motor connected but not running, DC voltage is applied to the motor at inverter power OFF and the capacitor's capacity is measured. |

Below 85% of the capacitor's original capacity. (10-year service life) |

Replaced by our after service team (contact your sales representative) |

| Control circuit capacitor |

The life is calculated from the energization time and temperature, and is counted down from 100%. |

Capacitor service life below 1 year. (10-year service life) |

|

| Inrush current limit circuit |

The number of contact ON times is counted down from 100%. |

Capacitor service life below 1 year. (10-year service life) |

|

| Cooling fan | The speed of the cooling fan is constantly monitored and any reduction in speed is detected. |

When fan speed falls below 50%. (10-year service life) |

User replaceable |

〈Applicable models〉

Using FR Configurator2, easy-to-use software assisting anything from setup to maintenance, much more useful functions are available for users.

A free trial version with limited functions is available for download via the

following link.

Parts service life data is displayed in a dedicated window.

A warning icon is shown in the alarm field of the parts recommended for replacement.

paired with a GOT

enclosure

By connecting a computer to the USB port on the front panel of the GOT, the

service life of multiple inverters can be checked using FR Configurator2 via the GOT.