Motion Control Software SWM-G Features

- Concept

- Features

- Numerous Motion Control Functions

- Covering a Wide Range of Multi-Axis Applications

- Integrated Test Tool SWM-G Operating Station

- Multiple Servo Amplifier Settings and Adjustments

- Free Trial Version SWM-G-W

- Sample Program

- Sample Libraries

- CC-Link IE TSN

- Servo Amplifier MELSERVO-J5/MELSERVO-JET

- Specifications

- Related Link

Concept

Features

Installed on a personal computer, SWM-G Motion Control Software can perform motion and network control.

- Supports a CC-Link IE TSN servo control system with the personal computer where RTX64 (real-time extension) is installed.

(RTX64 is included with SWM-G.) - Meets various application needs by offering various types of motion control, such as positioning, synchronous, cam, speed, and torque control using API library for motion control.

- Utilizes network control to connect and set various device stations (remote I/O modules, etc.) and TCP/IP devices.

SWM-G

- Maximum number of control axes: 128

- Minimum operation cycle: 125 μs

- Programming language: Visual C ++®

- USB key (license):

- MR-SWMG16-U: 16 axes

- MR-SWMG32-U: 32 axes

- MR-SWMG64-U: 64 axes

- MR-SWMG128-U: 128 axes

SWM-G-N1

- Maximum number of control axes: 128

- Minimum operation cycle: 125 μs

- Programming language: Visual C ++®

- USB key (license):

- MR-SWMG16N1-U: 16 axes

- MR-SWMG32N1-U: 32 axes

- MR-SWMG64N1-U: 64 axes

- MR-SWMG128N1-U: 128 axes

SWM-G-W

- Maximum number of control axes: 64

- Programming language: Visual C ++®

Numerous Motion Control Functions

Positioning Control

In this method, an axis can be accelerated gradually through adjusting jerk so that the vibrations of the machine can be minimized.

In the example above, the constant positive jerk is applied at the start of the operation to achieve smooth acceleration.

When the axis is shifted to the constant-speed operation, the same amount of negative jerk is applied.

Adjusting jerk in this way achieves smooth acceleration/deceleration while also shortening the time it takes to reach the target speed.

The speed creates a S-curve shape.

The triggered motion is a type of command that delays the execution of the motion command until the specified trigger condition is satisfied.

Axes can be started automatically based on the specified conditions by using this command, reducing the cycle time of conveyor systems, etc.

In the operation example above, right after the axis 2 starts execution of normal motion commands, the axis 1 executes the triggered motion command (delaying the execution of the command until the condition is satisfied).

When the condition is satisfied (start trigger ON) during the axis 2 operation, the axis 1 starts executing the motion command.

Motion Control Software enables tandem operation where the same commands can be outputted to master and following axes.

After the master and following axes pass their respective dogs, the gantry home position return stops both of the axes at the Z-phase of the master axis.

This method enables two or more axes to execute home position return simultaneously, supporting gantry systems.

A Wide Variety of Features

The hot connect enables a topology change during operation without requesting a communication stop.

The user application disconnects and reconnects the network through API library.

The controller obtains the status data of servo amplifiers, such as machine diagnosis information and encoder temperature,

via CC-Link IE TSN. This enables visualization of machine status.

The output signal is turned on when a specified condition is satisfied. This function can be used as an alternative to a limit switch.

The current value of the servo motor can be read when the touch probe signal is inputted.

Software and hardware touch probes are available.

Select the touch probe according to your application.

The set offset is applied at regularly spaced command positions. The position error of ball screws can be compensated, improving the operation accuracy.

The set offset is applied when the axis changes the travel direction.

The backlash of ball screws can be compensated, which improves operation accuracy of machines.

The controller offers 24 types of acceleration/deceleration methods, such as trapezoidal, S-curve, jerk ratio, parabolic, sine curve, time acceleration trapezoidal, etc.

Select the method according to your application.

Covering a Wide Range of Multi-Axis Applications

- SWM-G Motion Control Software is available in 16 to 128-axis control models, enabling multi-axis synchronization of various scales of machines.

- A CPU core of the industrial personal computer is assigned for running SWM-G processing, and that enables SWM-G to perform a high-speed, real-time operation without being affected by the operation on Windows®.

Integrated Test Tool SWM-G Operating Station

This tool provides a variety of features - parameter settings required for application development and the test operation for JOG, inching, and positioning operations. In addition, each axis status and sampled waveforms can be displayed to help user check the start timing and the operation pattern.

[Parameter setting]

- Set/check parameters of each axis on the list.

- Import/export a setting file from/to the personal computer.

[Communication setting]

- Set IP address, axis No., and communication cycle of remote stations.

- Import/export a setting file from/to the personal computer.

- Remote stations are automatically set depending on the communication status.

[Communication monitor of master station]

- The communication monitor shows a list of communication setting of the master station.

- Check the communication status on the system status.

[Communication monitor of remote stations]

- Check the network status and IP address of remote stations.

[Details of remote station status]

- Check details of network status of remote stations, and perform a communication test.

[Single-axis control]

- Perform a test operation for single-axis control.

- A repeat operation is available, which is often used for a test operation.

Multiple Servo Amplifier Settings and Adjustments

MR Configurator2 enables users to easily set and adjust multiple servo amplifiers through CC-Link IE TSN which enables mixing of TCP/IP communication and other communications.

Using MR Configurator2 with the integrated test tool, users can adjust servo amplifiers while checking the servo amplifier communication status.

- Supports MR-J5-G

- Manages a multi-axis system as one project

- Parameters and the machine diagnosis can be set for all axes in a batch on MR Configurator2.

*MR Configurator2 is not included with SWM-G Motion Control Software.

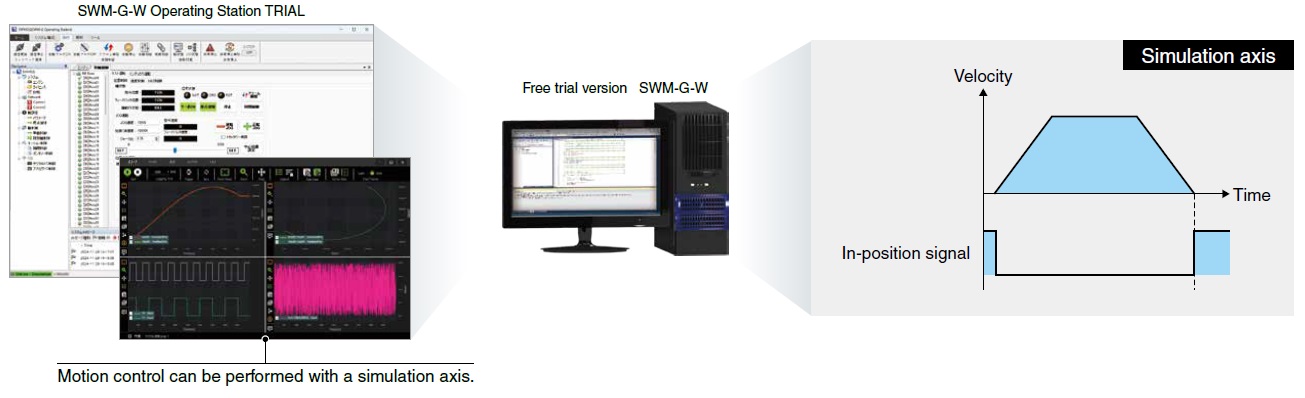

Free Trial Version SWM-G-W

Using the Free Trial Version SWM-G-W without a USB Key (License)

SWM-G-W is a free trial version that can be used for an unlimited period without a USB key (license). The simulation axis can be operated, and the created programs can be used on SWM-G/SWM-G-N1. It operates on Windows® and does not occupy CPU cores.

| Free trial version SWM-G-W | SWM-G(-N1) | |

|---|---|---|

| USB key (license) | Not required | Required |

| RTX | - | Included |

| Maximum number of control axes | 64 axes | 128 axes |

| Servo amplifier | - | MR-J5-G(-N1) |

| Simulation axis | Included | Included |

Motion Control with Simulation Axes

Programs can be checked with simulation axes.

This enables a program check without servo amplifiers from the debugging stage, shortening the startup time.

Sample Program

This tool provides a variety of features - parameter settings required for application development and the test operation for JOG, inching, and positioning operations. In addition, each axis status and sampled waveforms can be displayed to help user check the start timing and the operation pattern.

Sample Libraries

API library for SWM-G Motion Control Software.

- ■API Library Linked with SoftGOT

-

- The API library enables users to easily exchange data of SWM-G Motion Control Software and SoftGOT2000.

- ■API Library Linked with Mitsubishi Electric Products

-

- The API library enables users to set parameters for CC-Link IE TSN-compatible analog I/O modules and servo amplifiers

(MELSERVO-J5 series).

- The API library enables users to set parameters for CC-Link IE TSN-compatible analog I/O modules and servo amplifiers

Open integrated networking across the manufacturing enterprise

CC-Link IE TSN supports TCP/IP communications and applies it to industrial architectures through its support of TSN enabling real-time communications.

With its flexible system architecture and extensive setup and troubleshooting features make CC-Link IE TSN ideal for building an IIoT infrastructure across the manufacturing enterprise.

- *TSN: Time Sensitive Networking

- *IIoT: Industrial Internet of Things

Servo Amplifier MELSERVO-J5/MELSERVO-JET

The MELSERVO-J5 series high-performance, industry-leading servo amplifiers

feature a unique control engine that is more powerful than ever before.

These servo amplifiers can connect to CC-Link IE TSN to perform high-speed, high-precision control.

Each multi-axis servo amplifier drives a maximum of either two or three servo motors (depending on the model of servo amplifier chosen), simplifying wiring and enabling a compact machine at a lower cost.

The MELSERVO-JET series high-performance servo amplifiers feature a unique control engine that is more powerful than ever before.

These servo amplifiers can connect to CC-Link IE TSN to perform high-speed, high-precision control.

The servo amplifiers support linear servo motors in addition to the rotary motors.

EtherCAT® is supported by MR-JET-G-N1.

Specifications

| Motion Control Software | |||||

|---|---|---|---|---|---|

| SWM-G(-N1)*3 | |||||

| Maximum number of control axes *1 | 16 axes, 32 axes, 64 axes, 128 axes | ||||

| Communication cycle (operation cycle settings) [μs] |

125, 250, 500, 1000, 2000, 4000, 8000 | ||||

| Network | CC-Link IE TSN, EtherCAT®*3 | ||||

| CC-Link IE TSN class | B | ||||

| Communication specifications | Mixture of hot connect, SDO communication, TCP/IP communication | ||||

| Development environment | • Microsoft® Visual Studio® 2017, 2019, 2022 • Programming languages supported by API library: C/C++, .NET (C#, VB.NET, etc.) |

||||

| Functions | Control method | Position, speed, torque | |||

| Positioning | Up to 128 axes simultaneously (absolute value command, relative value command), override | ||||

| Acceleration/deceleration processing |

Trapezoidal, S-curve, jerk ratio, parabolic, sine, time acceleration trapezoidal, etc. (24 types) |

||||

| Interpolation | 2- to 4-axis linear interpolation, 2-axis/3-axis circular interpolation, 3-axis helical interpolation, PVT | ||||

| Continuous path | Combination of linear and circular interpolation, spline interpolation, pre-read speed automatic control, linear/circular continuous path with rotation stage | ||||

| JOG operation | Provided | ||||

| Real-time control | Event, triggered motion, position synchronous output | ||||

| Synchronous control | Simple synchronization, synchronous gear ratio, synchronous phase offset, synchronous compensation, dynamic establishment/cancellation of synchronization, multiple pairs (up to 64 pairs) of synchronization between 1 axis and multiple axes (synchronous group) |

||||

| Electronic cam | Cam curves of eight systems can be defined, cam curve per communication cycle, phase operation, clutch |

||||

| Home position return *2 | Home position return using the Z-phase, home position sensor, limit sensor, limit proximity sensor, external input signal, mechanical end, and gantry axis can be performed. |

||||

| I/O size | Input: 8000 bytes, output: 8000 bytes | ||||

| Compensation function | Backlash/pitch error compensation, plane strain (straightness) compensation | ||||

| Auxiliary function | Touch probe, logging | ||||

- *1.The maximum number of control axes differs among the USB keys for Motion Control Software.

- *2.SWM-G does not support the home position return mode of the servo amplifier.

- *3.SWM-G-N1 is also compatible with EtherCAT®.