Motion module Product Outline

Concept

These Motion modules with multiple-core processors enable to configure a high-speed, large system by supporting the CC-Link IE TSN real-time open network.

- Performs positioning control such as linear interpolation using function blocks. The programming is easy: users just need to set positioning data to the function blocks.

- Connects to various modules such as servo amplifiers and I/O modules via CC-Link IE TSN. This connectivity allows you to configure a servo system more flexibly.

- Supports a consistent engineering environment that is capable of handling tasks ranging from system design to debugging and maintenance.

Selection of mode

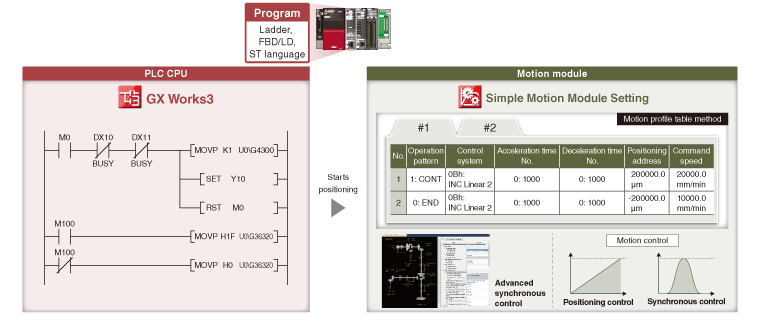

You can select the appropriate mode from the two operating modes, considering the programming language or project heritage, etc.

- ●Positioning control can be easily performed with motion profile tables. Synchronous control can be executed only with parameter settings.

- ●Remote devices are connected via CC-Link IE TSN and programmed from PLC CPUs.

- ●Data that is synchronized with the motion operation cycle can be collected with the digital oscilloscope. The collected data is displayed in waveforms for operation verification.

[An example of programming by a PLC CPU]

More details of the Simple Motion mode

- ●Supports ST language for programming while a PLC CPU supports ladder, FBD/LD, and ST language.

- ●Utilizes the library of PLCopen® Motion Control FBs, which are compliant with international standards, for programming.

- ●Enables users to analyze the operation status with logging data on GX LogViewer, improving debug efficiency.

[An example of programming by PLC CPU

(Programming by PLC CPU only) ]

![[An example of programming by PLC CPU (Programming by PLC CPU only) ]](./assets/img/feat_fb-01.png)

A PLC CPU program starts operation of the Motion module, eliminating the need for users to create another program for the Motion module, reducing programming burden.

[An example of programming by each module

(Programming by PLC CPU and Motion modules) ]

![[An example of programming by each module (Programming by PLC CPU and Motion modules) ]](./assets/img/feat_fb-02.png)

Motion modules can execute operations in place of the PLC CPU. This reduces the operation burden on the PLC CPU and results in a shorter cycle time.

Open integrated networking across the manufacturing enterprise

CC-Link IE TSN supports TCP/IP communications and applies it to industrial architectures through its support of TSN enabling real-time communications.

With its flexible system architecture and extensive setup and troubleshooting features make CC-Link IE TSN ideal for building an IIoT infrastructure across the manufacturing enterprise.

- * TSN: Time Sensitive Networking

- * IIoT: Industrial Internet of Things

Servo Amplifier MELSERVO-J5/MELSERVO-JET

The MELSERVO-J5 series high-performance, industry leading servo amplifiers feature a unique control engine that is more powerful than ever before.

These servo amplifiers can connect to CC-Link IE TSN to perform high-speed, high-precision control.

MR-J5W-G/MR-J5W-B multi-axis servo amplifiers and MR-J5D-G4 drive units simplify wiring and enable a compact machine.

*1.MR-J5-G/MR-J5D1-G4 support 31.25 μs.

The MELSERVO-JET series high-performance servo amplifiers feature a unique control engine that is more powerful than ever before.

These servo amplifiers can connect to CC-Link IE TSN to perform high-speed, high-precision control.

The servo amplifiers support linear servo motors in addition to the rotary motors.