Controllers MELSEC iQ-R Series Product features -Energy measuring-

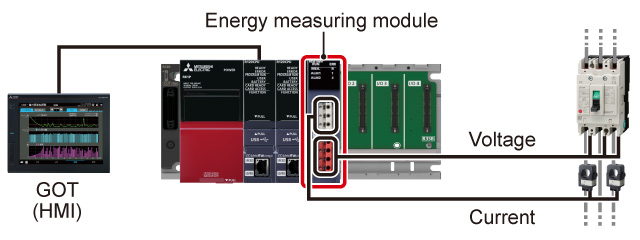

Energy measuring module

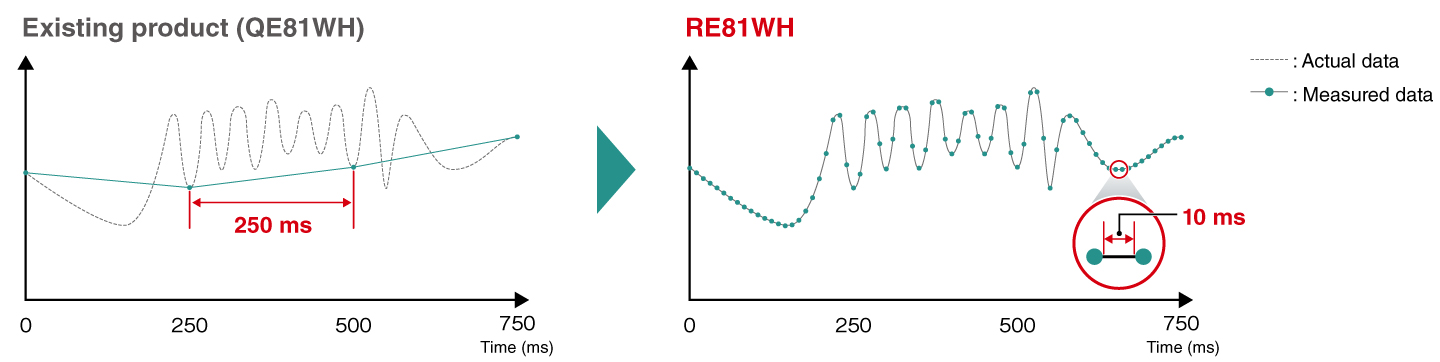

The energy measuring module can process measured data at a refresh cycle of 10 ms and is ideal for energy saving and predictive maintenance at the manufacturing site.

Features<sup>Highly detailed energy measurements by simple setting and installation</sup>

- Easy installation and setting

- Highly detailed measuring

- By directly installing the module on a vacant slot of the base unit, measurement functions can be added without changing the layout in the control panel

- Setup is easily done with the engineering software GX Works3 without having to develop a program

- Highly detailed energy measuring at a refresh cycle of 10 ms, which is ideal for manufacturing equipment for beverage and semiconductor industries

Visualize CO2 emissions and other data in coordination with e-F@ctory starter package

- CO2 emissions management

- Visualization

- CO2 emissions, specific energy consumption, production volume, and electric energy can be easily checked with free sample projects of programmable controller and GOT (HMI)

- CO2 emissions are displayed on the GOT (HMI) allowing real-time monitoring on the shop floor. This will help raise awareness of CO2 emission reduction in manufacturing

- Electric energy and production volume data are saved for energy loss analysis per production line and equipment process

Specifications<sup>Energy measuring module specifications</sup>

| Item | RE81WH |

|---|---|

| Number of measurable circuits | 1 |

| Phase-wire systems | Single-phase 2-wire, single-phase 3-wire, three-phase 3-wire common |

| Current circuit (A AC) | 5, 50, 100, 250, 400, 600*1 5*2 |

| Voltage circuit | |

| Single-phase 2-wire, three-phase 3-wire (V AC) | 110, 220 common*3 |

| Single-phase 3-wire (V AC) | 110 (1-2 lines, 2-3 lines), 220 (1-3 lines) |

| Measurement specifications | |

| Data refreshing cycle (ms) | 10…10000*4 |

| Measurement items | Current, current demand, voltage, electric power, electric power demand, reactive power, apparent power, harmonic current, harmonic voltage, frequency, power factor, electric energy, reactive energy |

- *1.A value when a dedicated split-type current sensor is used. Each value indicates current sensor's primary current value.

- *2.A value when a dedicated 5 A current sensor is used. A 5 A current sensor is used with two-stage configuration in combination with a current transformer (CT). Primary current value can be set up to 6000 A.

- *3.Up to 6600 V can be set in combination with a voltage transformer (VT).

- *4.Can be set in increments of 10 ms.