It sped the process up tremendously

First released March, 2022

“With the new system, we can look at the report and we can go right to the problem areas. It allows us to make improvements right away.”

Tony Ingram, Senior Staff Engineer, FCC (Adams), LLC.

FCC (ADAMS), LLC- Car parts manufacturer, US -

Plant Increases Efficiency with Mitsubishi Electric

In manufacturing, speed and accuracy are paramount. Anything that slows down production can have a significant effect on a company's bottom line. When manufacturer FCC (Adams) wanted to improve its efficiency, reporting ability, simplify visualization on the production line, and become more cost-effective. Mitsubishi Electric Automation was able to help the company achieve its goals in spectacular fashion.

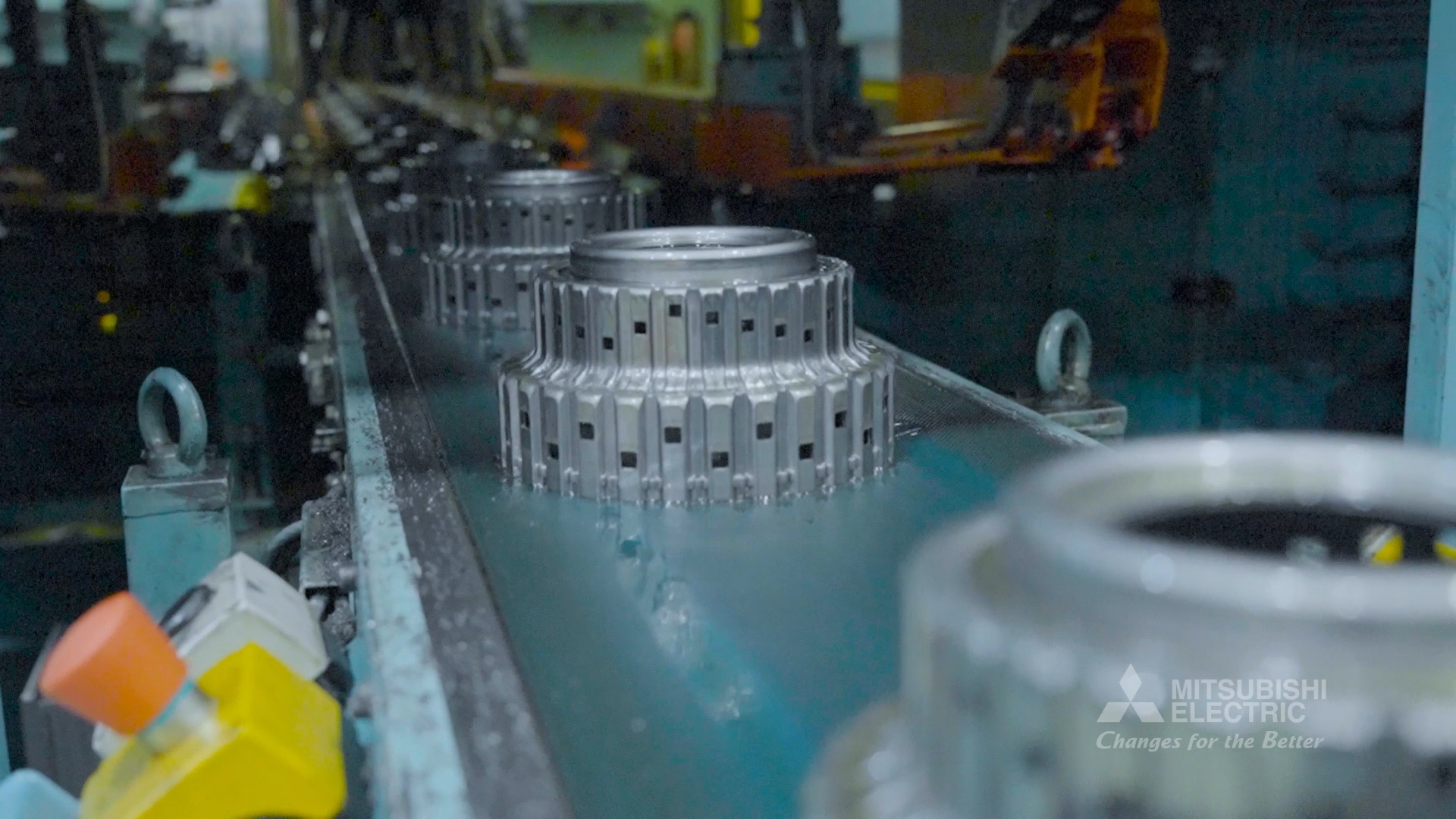

Headquartered in rural Berne, Indiana, FCC (Adams) creates automatic transmission clutch assemblies and components for major automotive companies in the United States and around the world. The company does everything from development of products, such as friction materials, to assembly.

Pen-and-Paper Processes Inhibit Productivity

FCC (Adams) wanted to modernize the way it collected and reported on production line data. The manufacturer has four main production lines, each containing several dozen stations. The data collection procedure at the time was completely manual, requiring station operators to record manufacturing problems or line issues throughout the day on paper forms, which were then processed by an employee, typing handwritten data into an Excel spreadsheet. This process left a wide margin for human error, whilst production reports were typically delivered to production manager Miyuki Lash, 24 hours later or more.

During daily production meetings, the team was limited in its ability to discuss specific issues and problems from the previous production day, due to the lag in reporting. Managers wanted the ability to react more quickly to areas that needed attention, such as station downtime or which machines were kicking out too often.

After learning about the possibilities of data collection solutions, Mitoshi Sawaki, Assistant Chief Engineer, and others informed company leaders of the opportunities this could deliver, and the manufacturer began to make plans to implement changes on the production floor.

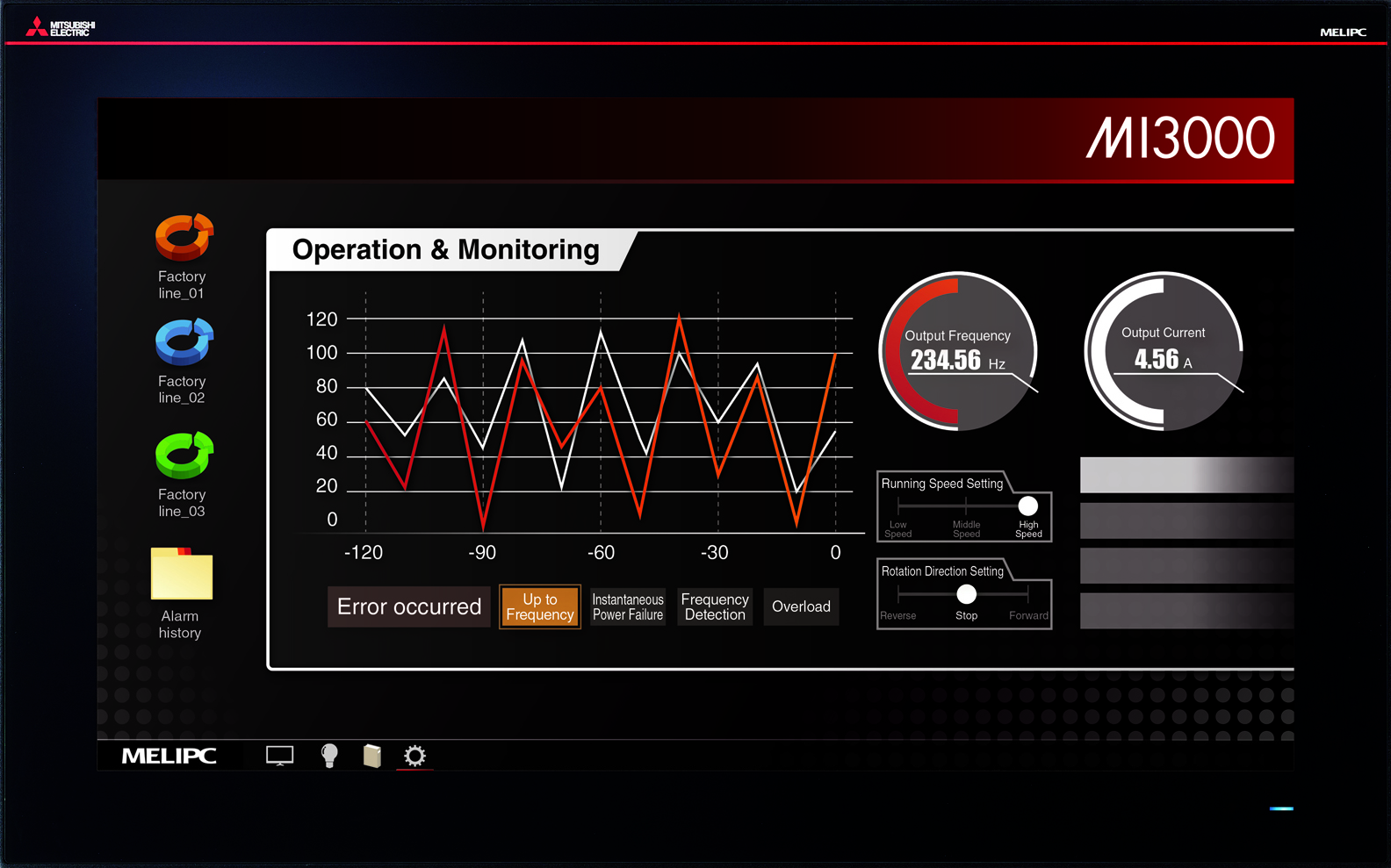

When connected to the assembly line, the MI3000 Industrial Computer provides automated, real-time visualization of the entire process, including any alarms or issues on the line itself.

Industrial PC Provides Real-Time Data Access

FCC (Adams) is a long-standing customer of Mitsubishi Electric and has been using Mitsubishi Electric PLCs, servos, and other products for years. Because of their consistent reliability, discussing a new data collection solution with them was a natural choice.

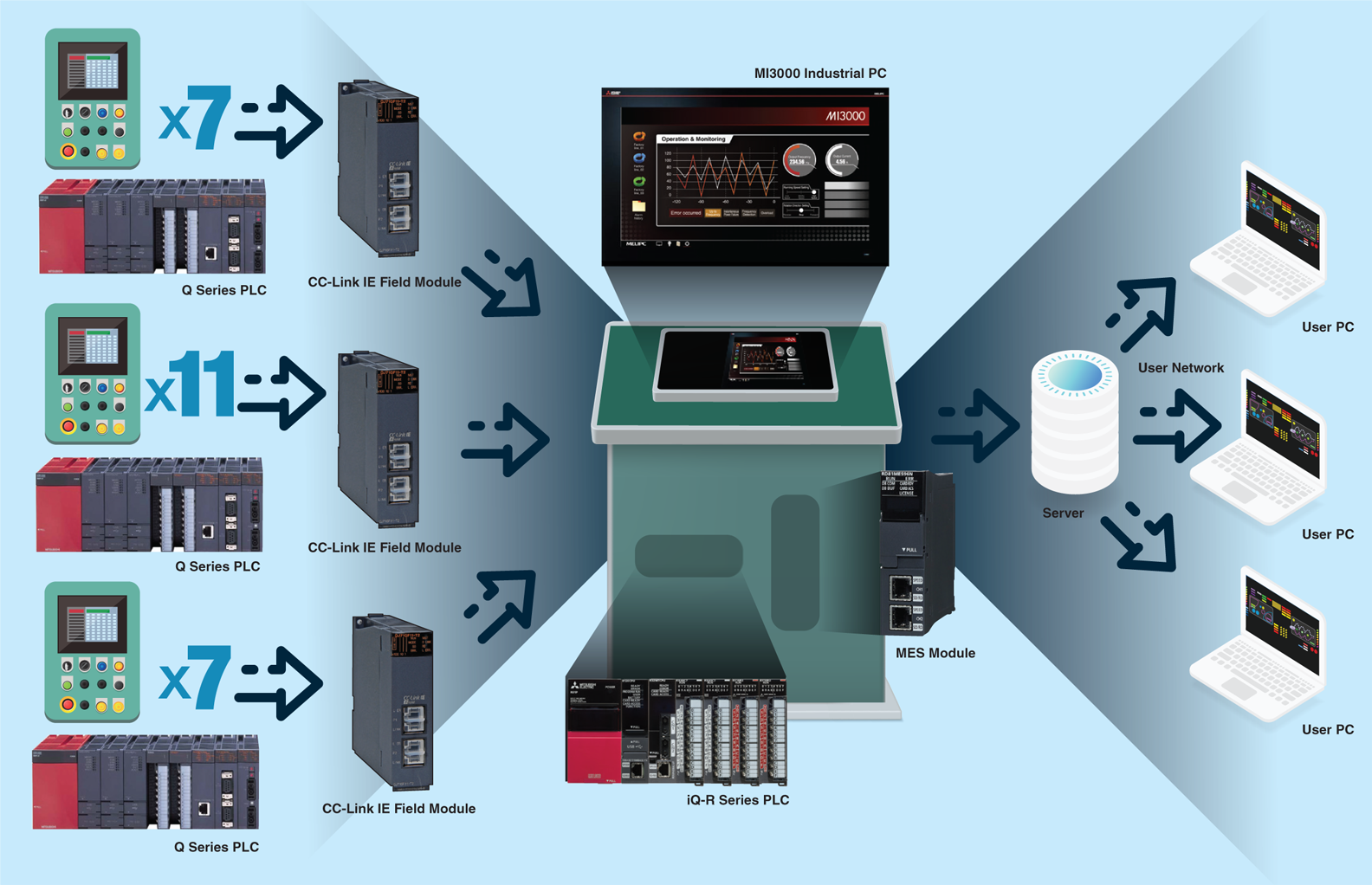

Mitsubishi Electric sales representative Daisuke Kumagai introduced the FCC (Adams) engineering team to the capabilities of the Mitsubishi Electric MI3000 Series industrial computer combined with the CC-Link IE Field Network.

These days, production Line 1 at FCC (Adams) is more efficient than ever ... production managers can see right where issues are occurring and address them quickly.

When connected to the assembly line, the MI3000 provides automated, real-time visualization of the entire process, including any alarms or issues on the line itself. It collects data seamlessly and compiles it into any number of reports as defined by the user.

The CC-Link network provides a full 10Mbit/s performance across the whole network, regardless of device type, eliminating hidden bottlenecks and allowing manufacturers to integrate a wide variety of automation components into a single, seamless automation system.

Mr. Sawaki said the team liked the Mitsubishi Electric solution for several reasons:

- It was a one-time purchase with no additional maintenance fees after installation.

- It offered an easy learning curve, thanks to the company’s high familiarity with Mitsubishi Electric network architecture and PLC software.

- It’s a flexible solution that can accommodate future design changes at FCC (Adams).

- The Mitsubishi Electric team were more than willing to fine-tune and optimize the solution after installation to meet FCC (Adams)’ specific needs.

- It allows flexible data output formats.

- Easy programming allowed us to pinpoint the specific data points for collection.

After FCC (Adams) contracted Mitsubishi Electric, the project commenced quickly and installation on Line 1 was completed in about a week. The solution was tailored to meet FCC (Adams) project specifications and system architecture to measure target production, actual production, efficiency (in %), and downtime, among other parameters. Once the system was tuned and optimized, everything changed.

Empowered to Do More, with Less

System Configuration Infographic

Today, production Line 1 is more efficient than ever. With automatic visualization of data in real time, production manager Lash can see where issues are occurring and address them immediately, reducing any lengthy unplanned downtime to a minimum.

"We went from basically using pencil and paper to having an accurate data collection system that helps us understand the issues that we have on a daily basis"

Tony Ingram, Senior Staff Engineer, FCC (Adams), LLC.

Senior staff engineer Tony Ingram says, "We were able to simplify our process through this, versus doing all this hands-on and going out to the machine and doing the recording and everything. Now it's right there, a few clicks on the computer and you've got the information you need."

It used to take at least two people to gather the line data and compile it into a report. Now just one person can manage the entire process and still have time to focus on other tasks.

"With assembly, there are a lot of component parts," says Lash. "We used to have a lot of discrepancy in our inventory counts, but now, even with one less person, we've been able to keep up a proper count and reduce losses."

Lash and Ingram agree on the three biggest benefits of the Mitsubishi Electric solution:

- 1.They're getting more accurate information about the line performance because it's no longer a manual process and subject to human error.

- 2.Line operators are working more efficiently because issues are addressed immediately.

- 3.The team is seeing significant time-savings in completing and reacting to necessary reports.

Now FCC (Adams) can automatically record operating status, alarm history, test results and other metrics on its machines and lines. The solution has allowed them to streamline, manage, and organize their data in a way that made it more readily usable.

Ingram says, "We went from basically using pencil and paper to having an accurate data collection system that helps us understand the issues that we have on a daily basis."

FCC (Adams) has expressed interest in automating their other three lines to reduce the amount of manual work and boost efficiency there, too.

Products and Solutions

FCC (ADAMS), LLC.

- Automatic transmission clutch assemblies and components manufacturer in US. In-house manufacturing capabilities include transfer press stamping / forming, Grob forming, flow-forming, aluminum die casting, electron beam welding, machining and assembly.

- URL : https://www.fcc-net.co.jp/en/