Supply Chain Management (Procurement)

Procurement Policy and Supplier Criteria

The Mitsubishi Electric Group mitigates procurement risks along the supply chain by providing an explanation of the Group’s Procurement Policy to suppliers and ensuring proper evaluation of suppliers based on selection and evaluation criteria.

The criteria for evaluating suppliers include not only quality, cost, delivery schedules and services, but also initiatives in response to environmental regulations and sustainability. As a basic policy, the Group preferentially procures materials from suppliers who rank high in our comprehensive evaluation.

In order to enhance the objectivity and transparency of human rights and environmental initiatives throughout the supply chain, in February 2022, we joined the Responsible Business Alliance (RBA), an alliance that promotes corporate social responsibility in global supply chains. We commit to progressively aligning our operations with the provisions of the RBA Code of Conduct, a global standard, to promote continuous improvement of our sustainability efforts.

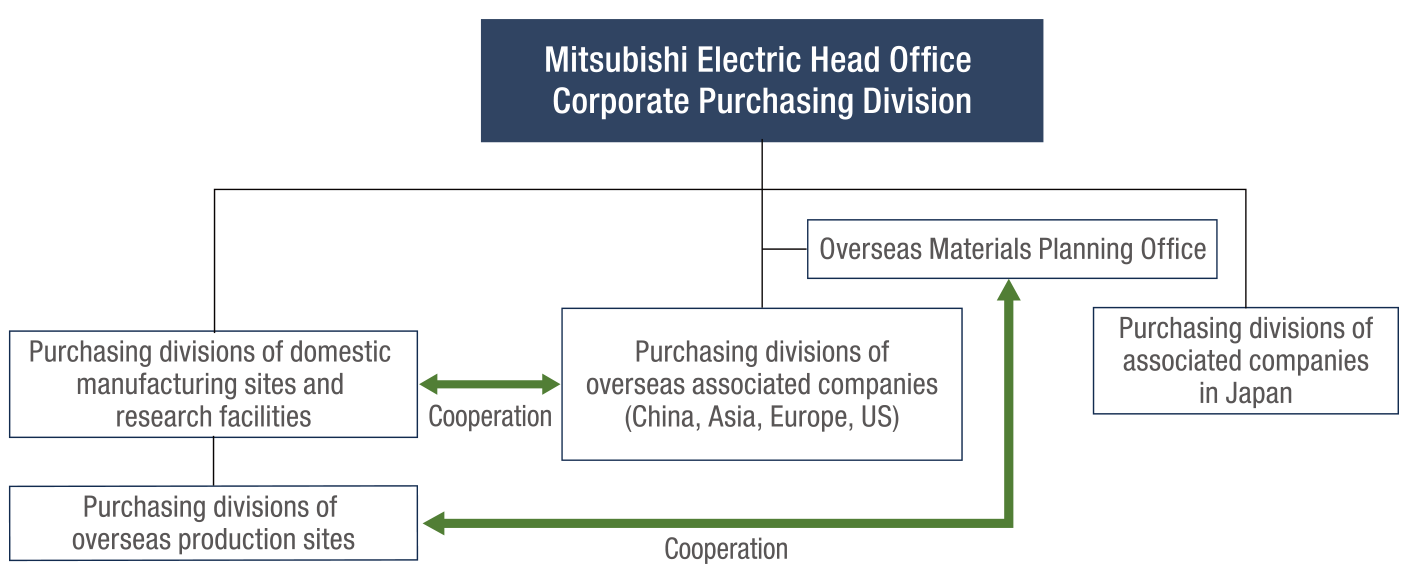

Framework for Promotion of Procurement Supply Chain Management

Under the framework shown below, the Mitsubishi Electric Group works on six priority activities to promote a more vigilant supply chain management.

Framework for promotion of procurement supply chain management

Framework for promotion of procurement supply chain management

Six Priority Activities

- Establishing a framework for strengthening stable procurement

- Further strengthening the cost planning activity

- Expanding centralized purchasing

- Strengthening procurement quality control

- Strengthening a procurement platform for supporting relevant activities and measures

- Strengthening global optimal procurement

In cooperation with the Materials Planning Office in regional corporate offices in China, Asia, Europe and the Americas, we implement purchasing strategies through conferences of procurement officers and other such meetings to promote global optimal procurement.

In addition to this initiative, we will also promote activities to mitigate any perceived risks regarding a range of issues related to labor practices and environmental problems in the procurement supply chain and thereby strengthen our business continuity plan (BCP).

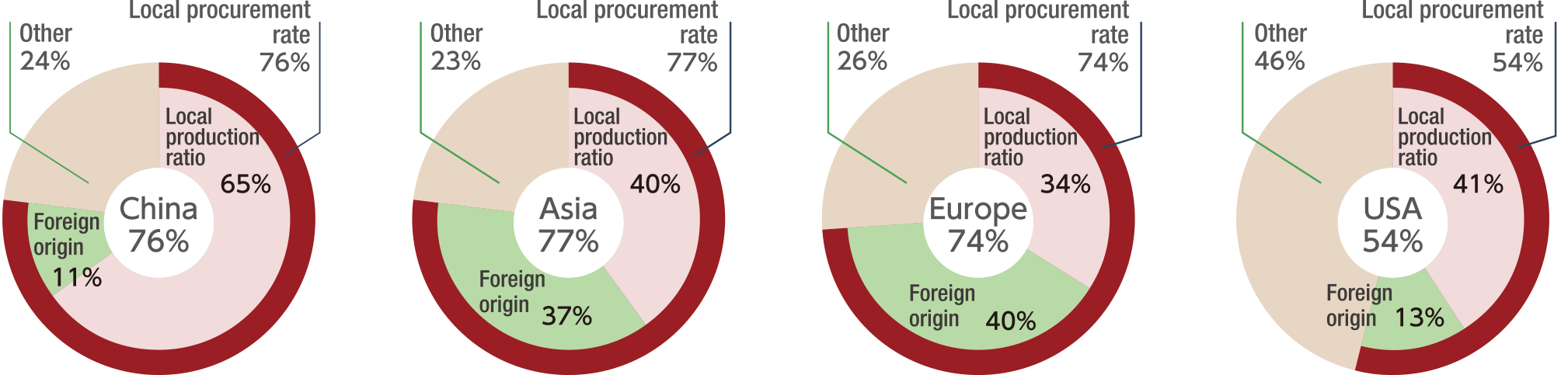

Local procurement rate* in the major regions (Mitsubishi Electric Group)

Local procurement rate* in the major regions (Mitsubishi Electric Group)

- Materials, parts, etc. (regardless of country of origin) that are procured by overseas production sites at their own discretion. Of these, the procurement ratio of items produced in the country of the overseas site is defined as the local production ratio, and the procurement ratio of items produced in countries other than the country of the overseas site is defined as foreign origin.

Mid- to Long-Term Priority Activity Objectives

Continuing Activities to Identify and Address Risks Involving Major Human Rights Violations (Forced Labor, Hazardous or Dangerous Labor, and Child Labor) in the Supply Chain

The Mitsubishi Electric Group asks its major suppliers to complete an annual questionnaire survey to determine, on an individual basis, the presence of especially major human rights violations risks, such as forced labor, dangerous or hazardous labor, and child labor. Through this process, we continuously strive to identify suppliers with high risk. In the Mitsubishi Electric Group Supply Chain Code of Conduct, we also include reduction of the number of excessive working hours and the right to a minimum wage, and we will continue to confirm this by means of the survey form.

Transitioning to RBA-Compliant Initiatives

Mitsubishi Electric joined the RBA in February 2022. In fiscal 2024, we established the Mitsubishi Electric Group Supply Chain Code of Conduct in alignment with the RBA Code of Conduct and held two explanatory sessions in June and November for approximately 800 supplier companies.

Online explanatory session for suppliers

Online explanatory session for suppliers

Establishing a Grievance Mechanism for the Entire Supply Chain

We joined the Japan Center for Engagement and Remedy on Business and Human Rights (JaCER) to strengthen our “grievance mechanism” for receiving and resolving grievances in the supply chain, and we have added a grievance point of contact.

Initiatives to Decarbonize Procurement Supply Chain Activities

The Environmental Sustainability Vision 2050 aims to achieve decarbonization in the entire value chain. We will grasp the level of reduction in CO2 emissions generated during production by suppliers and call for further reductions. In fiscal 2024, we conducted a survey on the status of carbon neutral initiatives and greenhouse gas emissions of our major suppliers. Based on the survey results, we will improve the accuracy of “greenhouse gas emissions in the value chain.”

Strengthening Sustainability Initiatives along the Procurement Supply Chain

Initiatives to Address Social Issues

From 2009, the status of sustainability initiatives has been included in the survey items, and a survey is also made of issues such as human rights, labor practices, safety and health, legal compliance, and product safety. In 2018, we also established the CSR Procurement Guidelines derived from the RBA Code of Conduct formulated and published by the RBA. In February 2023, we newly established the Mitsubishi Electric Group Supply Chain Code of Conduct, which is compliant with the RBA Code of Conduct. We confirm suppliers’ agreement with our Supply Chain Code of Conduct and supplier surveys.

Initiatives to Address Environmental Issues

Since 2006, the Mitsubishi Electric Group has been evaluating the progress of suppliers’ initiatives to address environmental issues under the Green Accreditation System. Based on the Green Accreditation Guideline, the System involves a survey of each supplier’s progress in acquiring environmental management system certification, the supplier’s status of compliance with laws and regulations related to the environment, and its management of chemical substances contained in components and materials they deliver to our company. Starting in 2024, we ensure proper evaluation of the progress of suppliers’ efforts to address environmental problems using survey forms that are compliant with the RBA Code of Conduct. Suppliers identified as being at risk are provided with appropriate advice and are requested to make corrections to mitigate any risk.

Toward Responsible Minerals Procurement

The Mitsubishi Electric Group aims for transparency in its procurement supply chain to avoid any affiliation with armed groups that trade in conflict minerals* as their source of funding. We also recognize the possibilities of human rights violations occurring in the severe labor conditions in cobalt mining sites as a major problem. The Group adheres to the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, and removes certain minerals from the procurement supply chain in situations where their procurement encourages or contributes to serious human rights violations or environmental destruction.

- Conflict minerals refer to gold, tin, tantalum, tungsten, and other minerals that have been determined by the U.S. State Department to be a source of support for armed groups when mined in OECD-defined conflict-affected and high-risk areas.

Report of Survey Results of Restrictions on Conflict Minerals

Mitsubishi Electric takes part in the Responsible Minerals Trade Working Group of the Japan Electronics and Information Technology Industries Association (JEITA) and addresses restrictions on conflict minerals in cooperation with other industry organizations. Surveys are conducted using the survey form (CMRT*1 and EMRT*2) that is commonly used in the automobile, electric, and electronic industries. In fiscal 2024, surveys were carried out on 1,178 suppliers, and responses in survey form were obtained from 927. As a result of the survey, 349 smelters were identified. Of the identified smelters, 219 were RMAP*3 compliant. We will continue to promote RMAP compliance among smelters through industry activities.

- 1 Conflict Minerals (tin, tantalum, tungsten, and gold) Reporting Template issued by the Responsible Minerals Initiative

- 2 Cobalt/Mica Reporting Template by the Responsible Minerals Initiative

- 3 Responsible Minerals Assurance Process: A program in which a third party certifies that the minerals processed by a smelter come from sources that are not complicit in conflicts or human rights abuses

Requests to Suppliers

The Mitsubishi Electric Group asks its suppliers to understand and comply with the Group’s Procurement Policy and Supply Chain Code of Conduct, and to inform their supply chains of these policies. Additionally, new suppliers are asked to understand the Group’s Supply Chain Code of Conduct and submit a written agreement to comply with it.

Evaluation Status of Suppliers’ Initiatives to Address Sustainability Issues

Basic Policy on Supplier Surveys

The Mitsubishi Electric Group verifies the progress of suppliers’ initiatives to respond to the requirements outlined in the Green Accreditation Guideline and the Mitsubishi Electric Group Supply Chain Code of Conduct by requesting major suppliers who fall within the top 80% in terms of purchase amounts to complete a survey form every year. In response to our suppliers’ replies to these surveys, we provide feedback about the results of the evaluation. We also communicate with suppliers who have scored low in any one of the survey items, to request the necessary corrections. This is done through individual meetings and other such means. The survey form has been revised in 2024 following the formulation of the Mitsubishi Electric Group Supply Chain Code of Conduct.

Activity Results

The supplier survey, launched in fiscal 2007 for suppliers in Japan, was expanded in fiscal 2018 to include overseas suppliers. Starting in fiscal 2025, we will conduct supplier surveys and remediation activities using the new RBA surveys. In fiscal 2024, we prepared for this implementation by providing explanations to suppliers.

Survey on Foreign Technical Intern Trainees

In fiscal 2020, Mitsubishi Electric conducted a survey of 390 main subcontract factories in the Mitsubishi Electric Group’s production activity on foreign technical intern trainees and obtained responses from all the companies surveyed. Among the companies surveyed, 136 companies hire technical intern trainees, and we confirmed with the suppliers as to whether they are certified as “excellent implementing organizations”* and the presence or absence of risks associated with implementing training (50 suppliers have been accredited as “excellent implementing organizations”). As a result of the survey, it was found that 24 out of 86 companies that have not been accredited as “excellent implementing organizations” are required to make improvements, which include displaying important signs for health and safety, such as hazardous materials and evacuation routes, in a language that trainees can understand. However, none of the suppliers were in violation of the Act on Proper Technical Intern Training and Protection of Technical Intern Trainees, the Labor Standards Act, etc.

We will provide guidance on items to be improved as well as continue promoting activities on an ongoing basis for preventing the violation of human rights of foreign technical intern trainees.

- An accreditation system administered by the Organization for Technical Intern Training (OTIT). A total score for a track record of acquiring the skills, the acceptance system, employment conditions of technical intern trainees, presence or absence of violations of laws and regulations, and consultation and support system for technical intern trainees of at least 60% of the full marks conforms to the criteria for the excellent implementing organizations. When a company is accredited as an excellent implementing organization, the intern training period is extended and the quota for the number of trainees accepted is increased.

Communication with Suppliers

At the Head Office and each business site, the Mitsubishi Electric Group periodically holds briefings for suppliers and exchange opinions to facilitate a full understanding of the Group’s Procurement Policy and the Mitsubishi Electric Group Supply Chain Code of Conduct among suppliers and gain their agreement. To promote sustainability initiatives at our suppliers, we also communicate with them in the areas of support for business continuity planning (BCP)* activities, management of chemical substances according to regulations such as the EU RoHS Directive, and compliance (including export control, information security and management, the Act against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors, etc.)

- Being prepared for any disaster or other emergency situation by planning how to minimize damage to the company and how to continue or restore business activities.

Initiatives for Strengthened Partnership with Suppliers

Mitsubishi Electric also participated in the Declaration of Partnership Building introduced in response to the discussion in the Council on Promoting Partnership Building for Cultivating the Future hosted by the Cabinet Office and the Ministry of Economy, Trade and Industry, and Mitsubishi Electric announced its declaration on July 1, 2020.

We have been conducting a supplier satisfaction questionnaire survey since fiscal 2021 aimed at improving business practices with suppliers and further strengthening the partnership based on the policy of building mutually-beneficial relationships as stated in the Declaration of Partnership Building.

In 2023, we conducted a survey following from the previous year with a total of 16 questions covering Mitsubishi Electric’s business attitude, ethics, compliance, and other topics in an attributed survey form for each supplier using a website.

We aggregate the responses from supplier questionnaires and analyze each survey item by comparing it with the results from the previous fiscal year, and we use the results to extract areas to be improved, to analyze causes, and to correct Mitsubishi Electric’s business attitude.

We will continue to conduct this activity in the future to utilize it to find potential issues in transactions with suppliers and to further promote improvement by taking the results seriously.

Value Engineering (VE) Activities with Suppliers

The Mitsubishi Electric Group engages in joint development from the initial stages to the development of parts and materials, and works in partnership with suppliers to engage in Value Engineering (VE) activities with the aim of adopting advanced technological products, recycling resources, and reducing the consumption of materials.

Through these activities, we reduce the input of materials and minimize environmental burden by making products more compact and lightweight, and build a win-win relationship that leads to increased sales and enhanced technology capabilities for both Mitsubishi Electric and our partners.

We also give awards to suppliers whose achievements are especially significant.

Mitsubishi Electric proactively conducts this activity to suppliers not only in Japan but also overseas, including in the UK, US, China, Thailand, Indonesia, Mexico, India, and Colombia. We also promote internal and external human capital development, such as by conferring an instructor’s certificate on those who have taken a written test and participated in the VE program in VE lectures, and demonstrated a certain level of knowledge.

VE lecture in China

VE lecture in China

VE lecture in Thailand

VE lecture in Thailand

Providing Learning Programs on Procurement Laws and Regulations

The Mitsubishi Electric Group offers various learning programs on laws and regulations related to the operations of employees in charge of procurement activities. In Japan for example, we hold lectures on laws and regulations that particularly pertain to procurement activities, such as the Anti-Monopoly Act, the Act against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors, and the Construction Business Act, and we provide guidance and training to ensure thorough compliance. Guidance and education are also provided overseas. Based on the Code of Conduct and check sheets, learning programs strictly teach employees not to become involved in bribery, embezzlement, or any other form of action that goes against the principle of fair trade. Compliance education related to procurement is also held for local employees in charge of procurement operations overseas. In addition, the Group is further strengthening sustainable procurement initiatives by sharing information on activities and guidance at each business site and holding regular learning sessions on sustainable procurement for employees of procurement departments.

Learning session on sustainable procurement for procurement department employees

Learning session on sustainable procurement for procurement department employees